A bonded lead-carbon composite negative electrode

A lead-carbon composite and bonded technology, applied in the direction of lead-acid battery electrodes, structural parts, battery electrodes, etc., can solve the problems of poor mechanical strength of negative electrode active materials, affecting charge and discharge cycle life, and inconvenient addition, etc., to achieve Improved service life, small internal resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

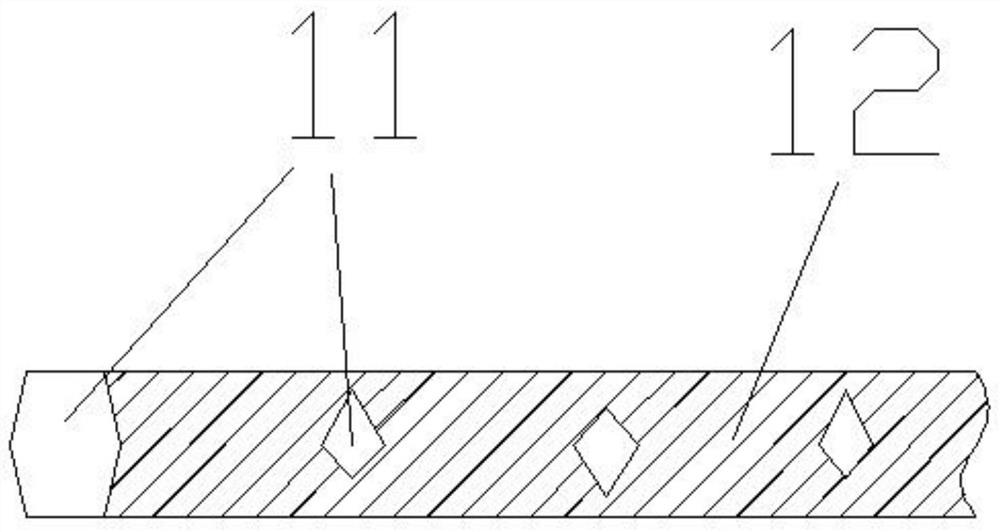

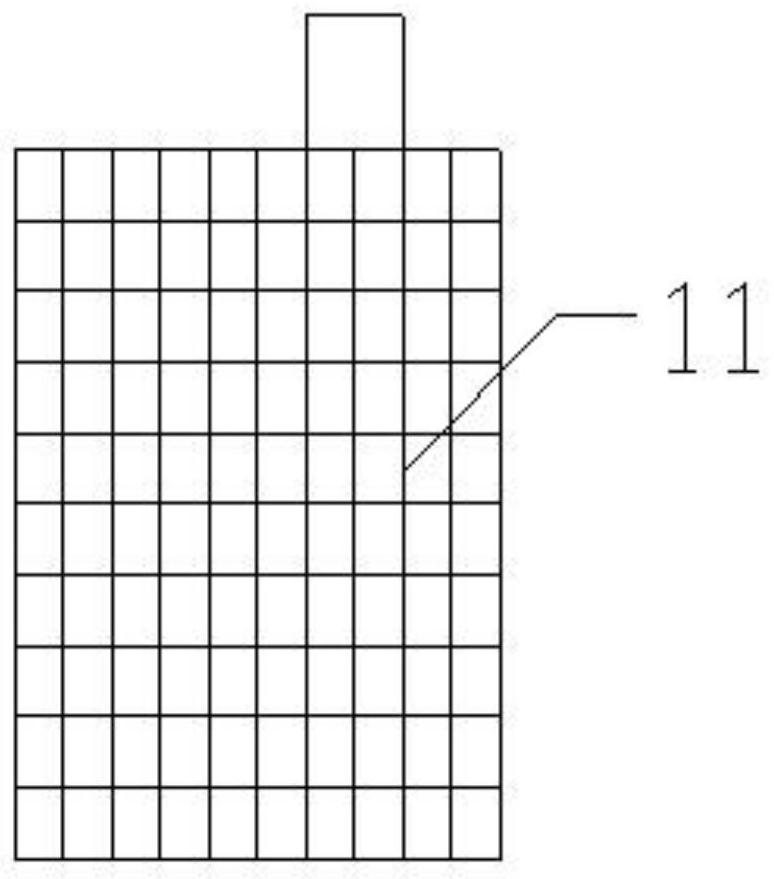

[0036] Example 1: Combining figure 1 , figure 2 and image 3As shown, the lead-carbon composite negative plate of this embodiment has a size of 68mm×44mm×3.0mm, and its specific composition and manufacturing method are as follows: evenly coat the lead-carbon composite material 12 on the current collector 11 (ie, the negative electrode grid). , and then repeated surface drying and rolling to form a dense material structure, and then secondary curing, that is, continuous curing for 12 hours at a temperature of 60°C and a humidity of 85%; then at 60°C and a humidity of less than 50% Next, continue to dry the negative plate for 24 hours. Such as Figure 4 As shown, in the finished lead-carbon composite negative electrode, in the negative electrode lead paste powder (active material) 121, carbon material 122 exists in an embedded manner.

[0037] The size of the current collector 11 is: 67mm×43mm×1.7mm, and it is made of a lead-calcium-tin alloy with a calcium content of 0.09%...

Embodiment 2

[0047] Embodiment 2: The lead-carbon composite material 12 is made up of negative electrode lead paste powder 121, carbon material 122 and water-soluble binder prepared through semi-curing and drying, and their respective mass percentages are: negative electrode lead paste powder Material 97.5%, carbon material 0.5%, polyvinyl alcohol 2%, among them, carbon material is activated carbon powder (commercialized product), parameter index: specific surface area 1500m 2 / g, mesoporosity greater than 40%, particle size 5 μm; its preparation method is: the negative electrode lead paste powder 121 that is prepared through semi-curing, add carbon material 122, water-soluble binder and appropriate amount of deionized water, use planetary The mixer mixes evenly to make an apparent density of 3.9g / cm 3 mortar material.

[0048] In the present invention, the semi-cured negative electrode lead paste powder 121 is to press the prepared negative electrode lead paste into a strip with a thickn...

Embodiment 3

[0050] Embodiment 3: The described lead-carbon composite material 12 is made up of negative electrode lead paste powder 121, carbon material 122 and water-soluble binder prepared through semi-curing and drying, and their respective mass percentages are: negative electrode lead paste powder Material 87%, carbon material 8%, CMC (carboxymethyl cellulose) 2.5%, polyvinyl alcohol 2.5%. The preparation method is as follows: add carbon material 122, water-soluble binder and appropriate amount of deionized water to the negative electrode paste powder 121 prepared by semi-curing, and mix evenly with a planetary mixer to make an apparent density of 3.95g / cm 3 mortar material.

[0051] The carbon material is modified carbon particles prepared by adding conductive agent and binder to activated carbon, and the weight ratio of each component is as follows: 55% of activated carbon, 5% of carbon nanotubes, 5% of carbon nanofibers, 5% of carbon black %, graphite powder 15%, acetylene black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com