Cleaning system and cleaning method of dry-jet wet spinning spinneret plate for preparing polyacrylonitrile protofilaments

A technology of polyacrylonitrile, dry spray and wet spinning, applied in spinneret assembly, textile and papermaking, etc., can solve the problems of poor cleaning effect, long cleaning time, affecting the spinning quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

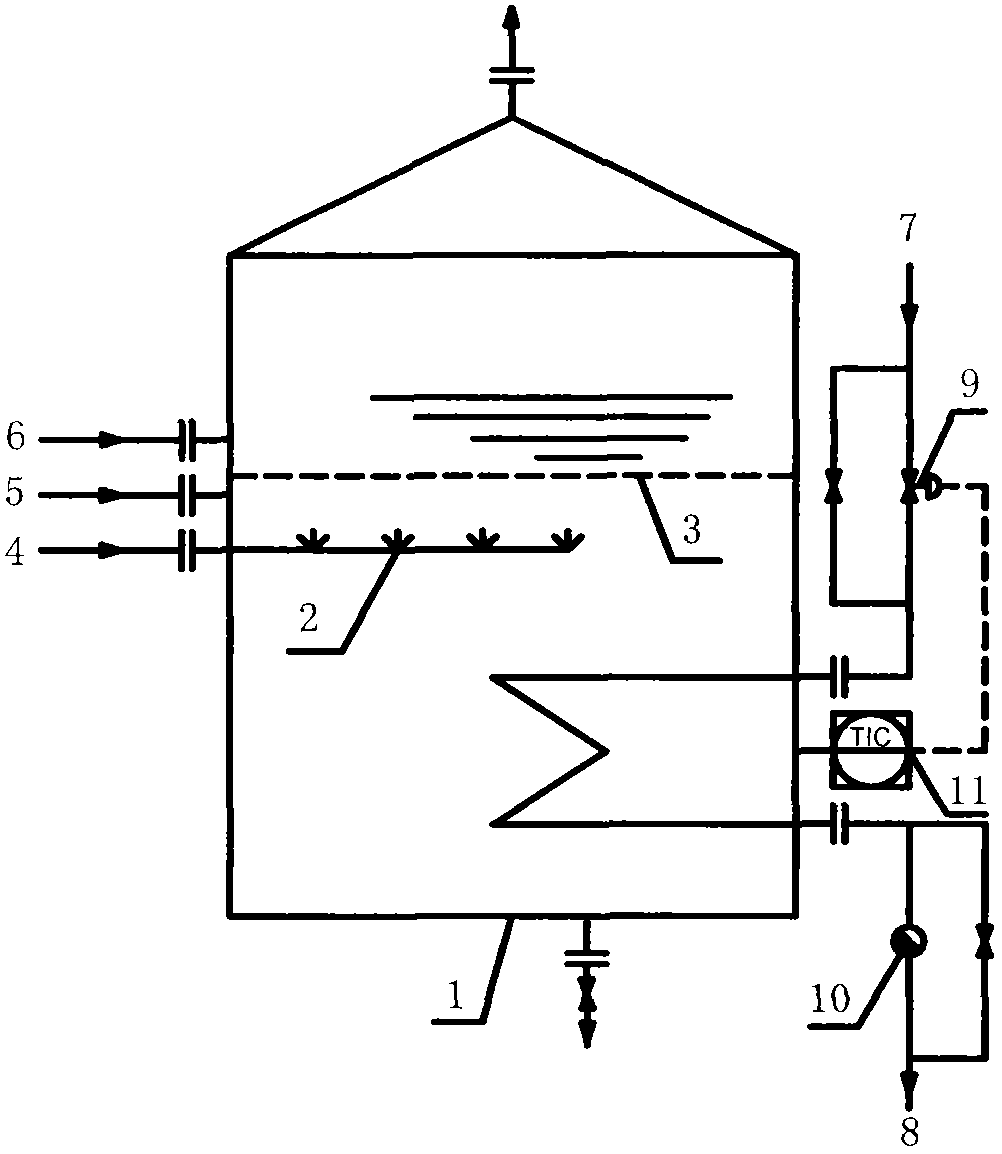

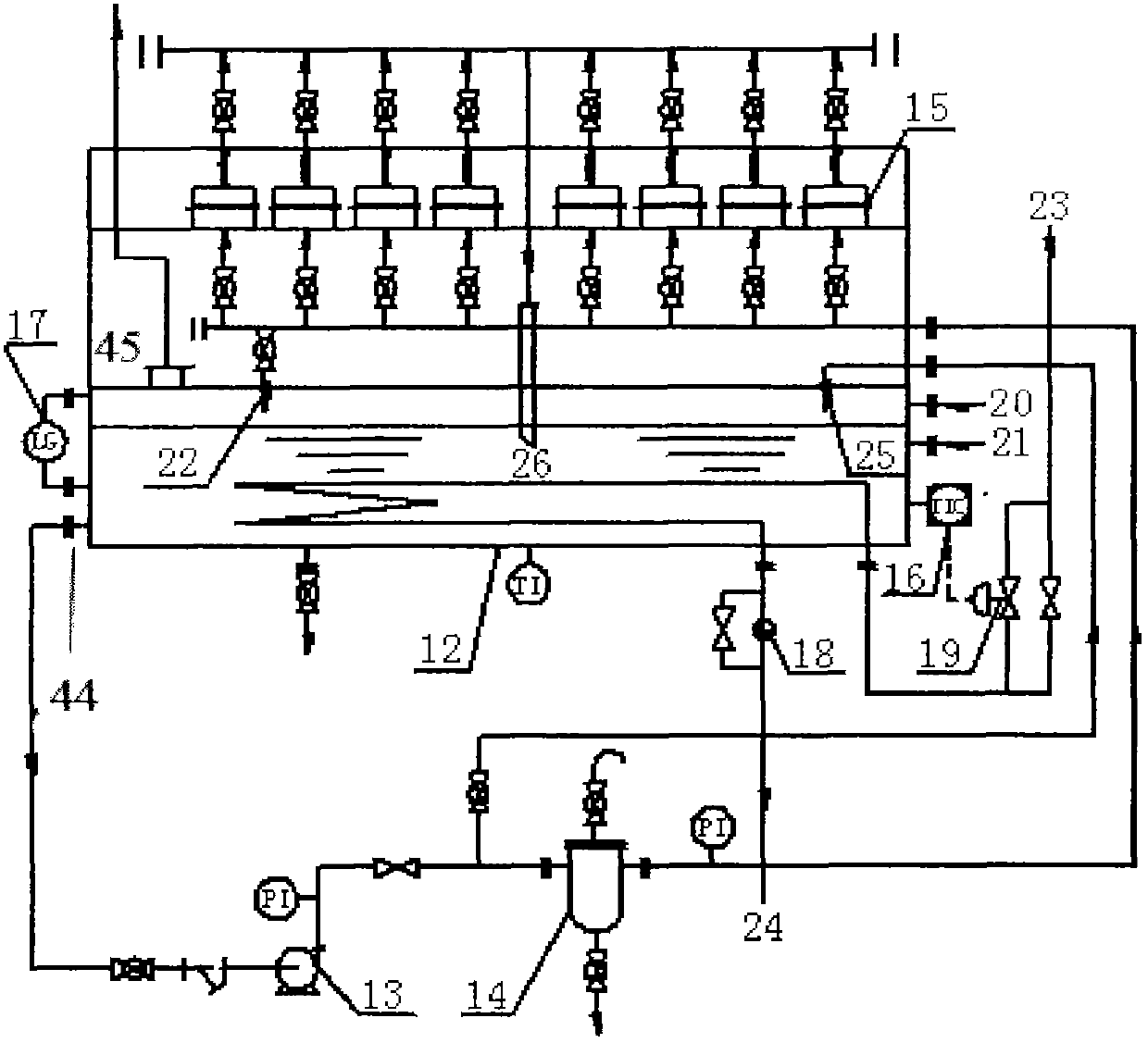

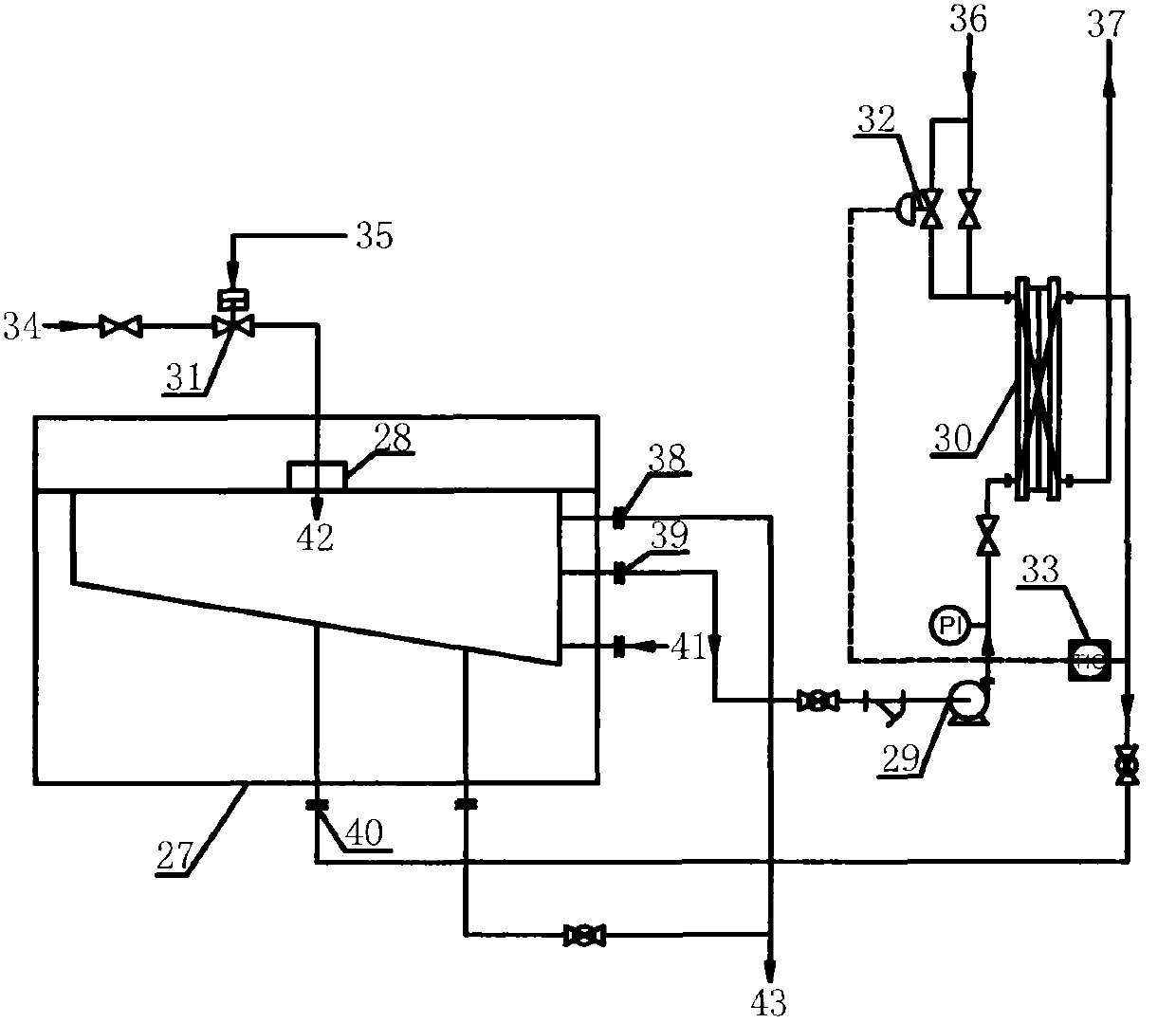

[0060] This embodiment provides a cleaning system for dry-jet wet spinning spinnerets for preparing polyacrylonitrile precursors, which includes a pre-soaking device, a circulation cleaning device, and a steam treatment device, and its structures are as follows: figure 1 , figure 2 , image 3 shown.

[0061] Such as figure 1 As shown, the pre-soaking device includes a spinneret pre-soaking tank 1, one side of the spinneret pre-soaking tank 1 is provided with a desalinated water inlet 6, a DMSO inlet 5, a compressed air inlet 4, and a spinneret A horizontal partition 3 is arranged inside the presoak tank 1, the height of the partition 3 is between the desalted water inlet 6 and the DMSO inlet 5, and the compressed air inlet 4 is connected to the nozzle 2 located inside the spinneret presoak tank 1, For input compressed air;

[0062] The inside of the spinneret presoak tank 1 is connected with a steam heating device, which is a steam heating pipeline, and the steam heating ...

Embodiment 2

[0068] This embodiment provides a method for cleaning the spinneret for dry-jet wet spinning for preparing polyacrylonitrile precursor, which uses the cleaning system provided in Example 1 to clean the spinneret according to the following steps:

[0069] (1) Pre-cleaning with DMSO solvent

[0070] a. Inject DMSO solvent enough to immerse the spinneret into the spinneret pre-soaking tank 1 through the DMSO inlet 5 to keep the liquid level in the tank at 60-70%, and at the same time, pass compressed air into the tank through the compressed air inlet 4 , and sprayed out from the nozzle 2 to ensure that the cleaning liquid is submerged in the spinneret and is in a flowing state;

[0071]b. Place the spinneret on the partition plate 3 in the spinneret pre-soaking tank 1, steam enters through the steam inlet 7 to heat the DMSO solvent in the spinneret pre-soaking tank 1, and adjust the regulating valve group 9 and The temperature controller 11 controls the temperature of the DMSO s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com