Centrifugal electrostatic continuous nanofiber spinning device

A nanofiber and continuous technology, which is applied in the field of centrifugal electrostatic continuous spinning nanofiber device, can solve problems such as difficulty in spinning, affecting spinning efficiency, and affecting the degree of filament thickness, and achieves high-efficiency spinning, high efficiency, and order controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

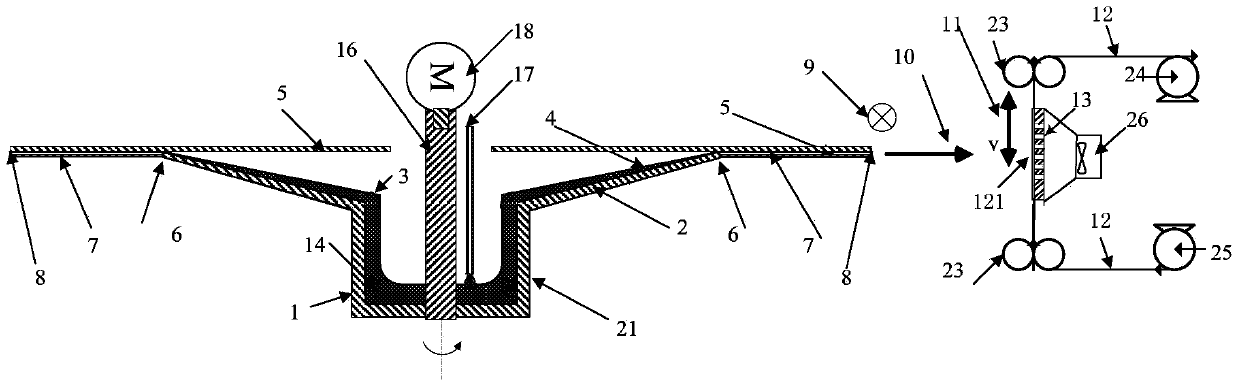

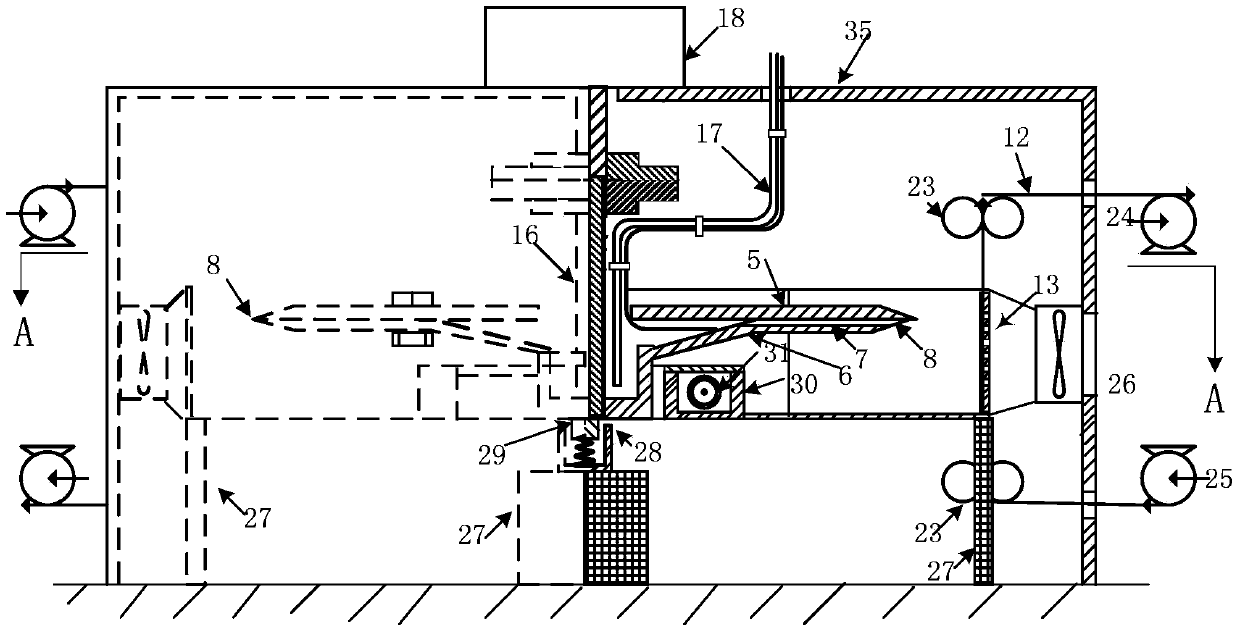

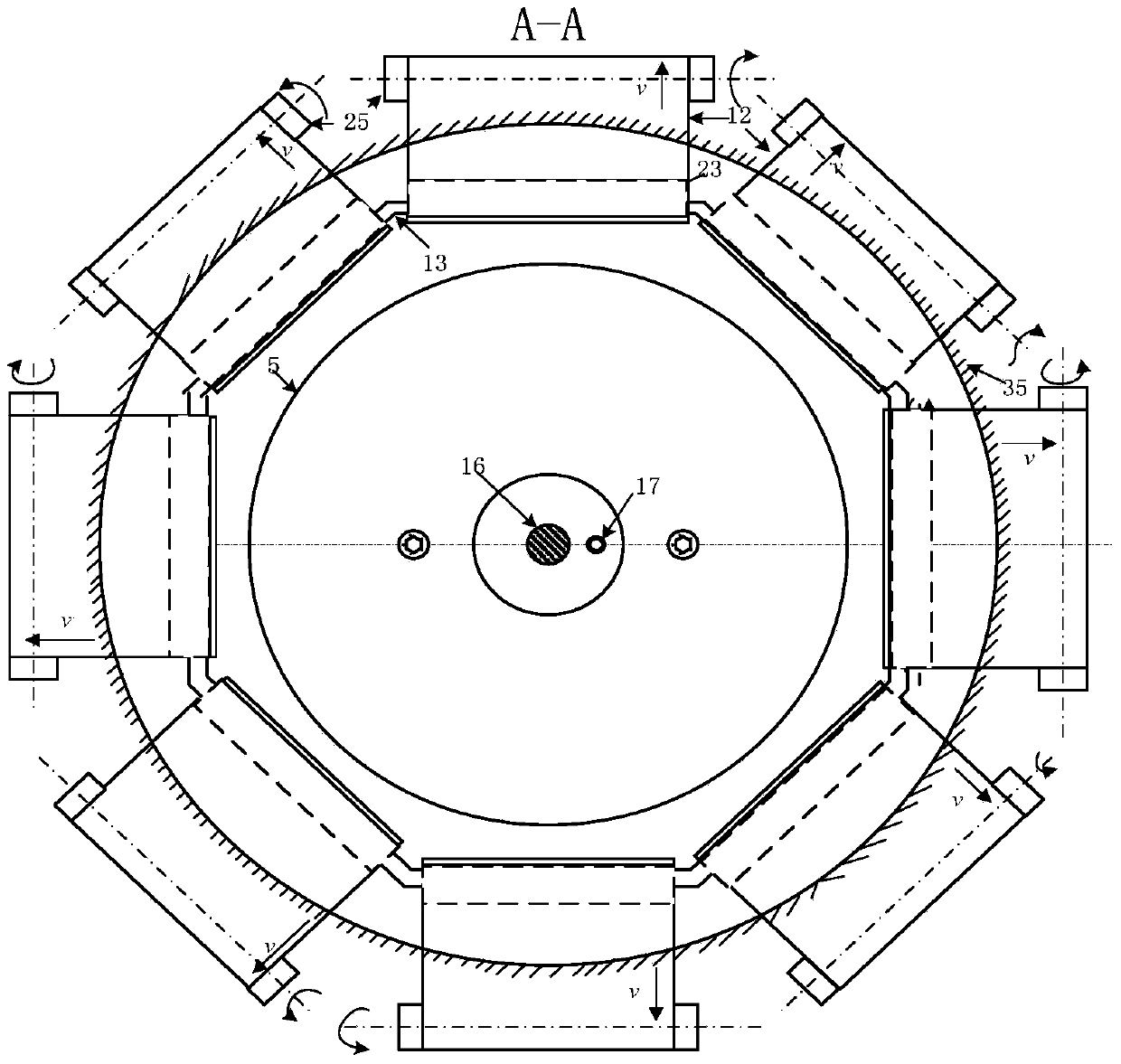

[0023] Example: Centrifugal electrostatic continuous spinning nanofiber device, such as figure 1 As shown, it includes a rotating cup 21 driven by a driving mechanism, a cover box and a cover ring 5 connected to the rotating cup 21 through a connecting piece; the rotating cup 21 includes a hollow cylindrical melting part 1, located The melting material film forming ring surface 2 at the upper end is externally connected to the annular spinning part 7 on the outer edge of the melting material film forming ring surface 2. The spinning part 7 is provided with a plurality of groups of spinning grooves 19 distributed radially, each group Spinning groove 19 comprises several passages containing melting material inlet 6 and melting material outlet 8, and each passage is bifurcated into two or more narrowed passages of width in the region of spinning part 7, and the bifurcation of passage A V-shaped cutting part is formed at the position, which is used to cut the melt film that is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com