Glossy knitted fabric and production method thereof

A production method and technology for knitted fabrics, applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve problems such as incompatibility, ecological environment affecting water repellency, etc., and achieve soft hand feel, good shape stability, and dimensional change rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

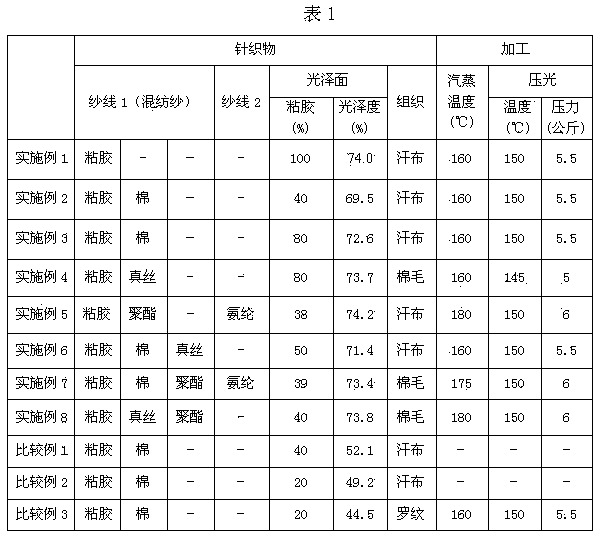

Embodiment 1

[0029] Use 30 S 100% viscose fiber yarn, of which the monofilament fineness of viscose fiber is 1.2dtex, is woven on a 28GG single-sided large circular knitting machine to obtain ordinary jersey knitted gray fabric, and then refined→dyeing with reactive dyes→reduction cleaning→fixation treatment→bath Medium softening processing (polyester hydrophilic softener 6% owf, 30 minutes, 40°C) → drying → high temperature steaming (temperature 160°C) → felt calendering (temperature 150°C, pressure 5.5 kg) → inspection, etc. After processing, the obtained gram weight is 160g / m 2 The performance parameters of knitted fabrics are listed in Table 1.

Embodiment 2

[0031] Use 30 S Cotton fiber / viscose fiber blended yarn (60:40), of which the monofilament fineness of viscose fiber is 1.2dtex, is woven on a 28GG single-sided circular knitting machine to obtain ordinary jersey knitted gray fabric, and then refined→dyeing with reactive dyes→reduction Cleaning→color fixing→softening in bath (polyester hydrophilic softener 8% owf, 30 minutes, 40°C)→drying→high temperature steaming (temperature 160°C)→calendering of woolen blanket (temperature 150°C, Pressure 5.5 kg) → After inspection and other processing, the obtained gram weight is 160g / m 2 The performance parameters of knitted fabrics are listed in Table 1.

Embodiment 3

[0033] Use 30 S Viscose fiber / cotton fiber blended yarn (80:20), in which the monofilament fineness of viscose fiber is 1.2dtex, is woven on a 28GG single-sided large circular knitting machine to obtain ordinary jersey knitted gray fabric, and then refined→dyeing with reactive dyes→reduction Cleaning→color fixing→softening in bath (polyester hydrophilic softener 6%owf, 30 minutes, 40°C)→drying→high temperature steaming (temperature 160°C)→calendering of woolen blanket (temperature 150°C, Pressure 5.5 kg) → After inspection and other processing, the obtained gram weight is 160g / m 2 The performance parameters of knitted fabrics are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com