Reinforcing structure for rear opening in shear wall and construction method of reinforcing structure

A technology of strengthening structures and opening holes in the back, applied in building construction, building maintenance, construction, etc., can solve problems such as weakening the bearing capacity of shear walls, and achieve the effects of simple and fast construction, reliable force, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

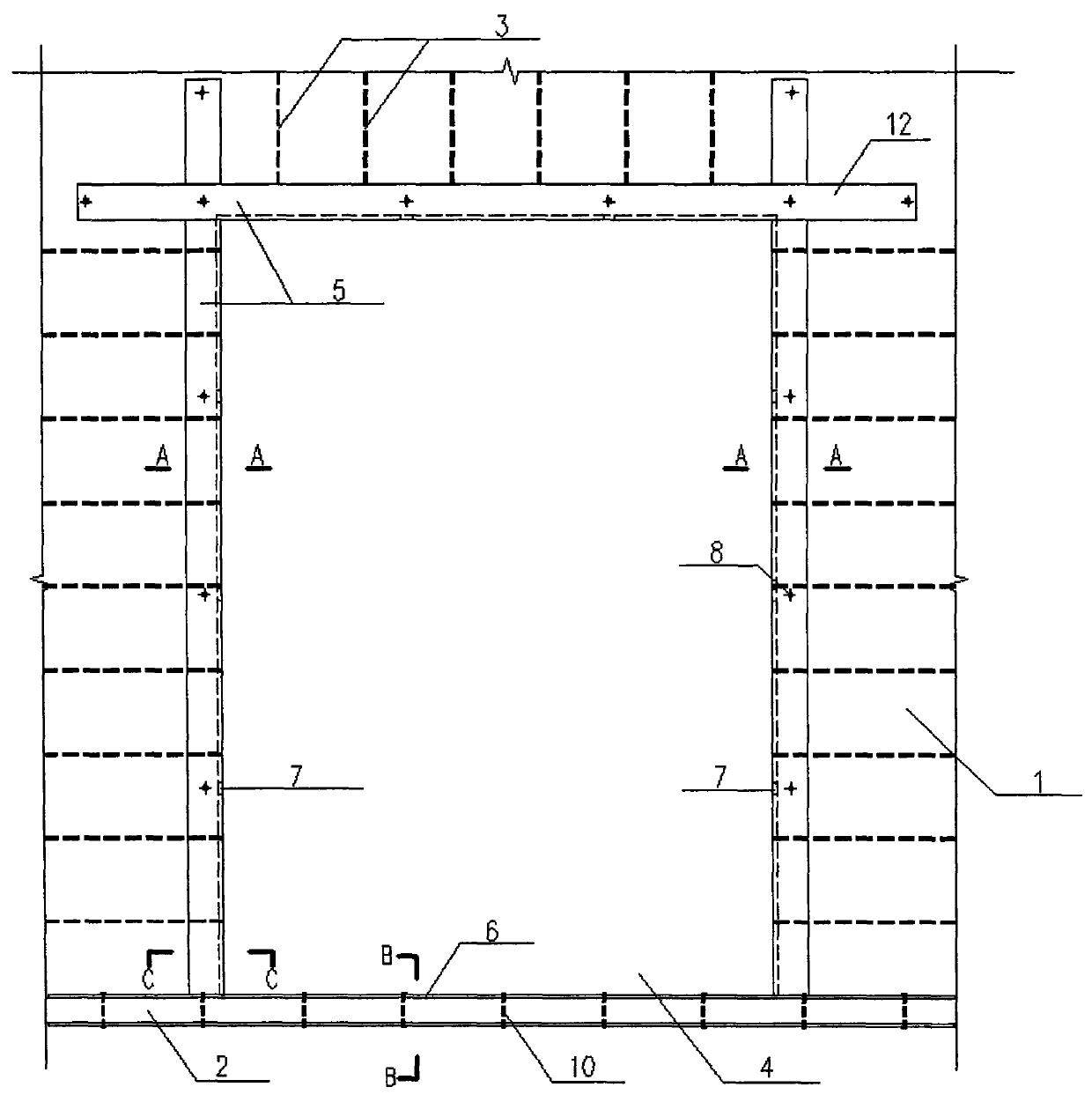

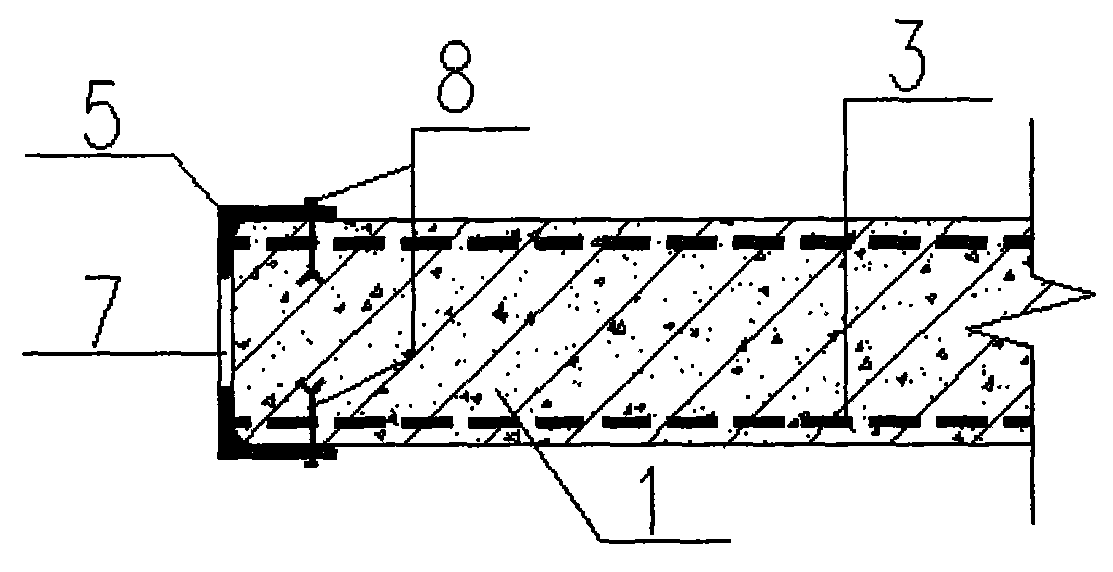

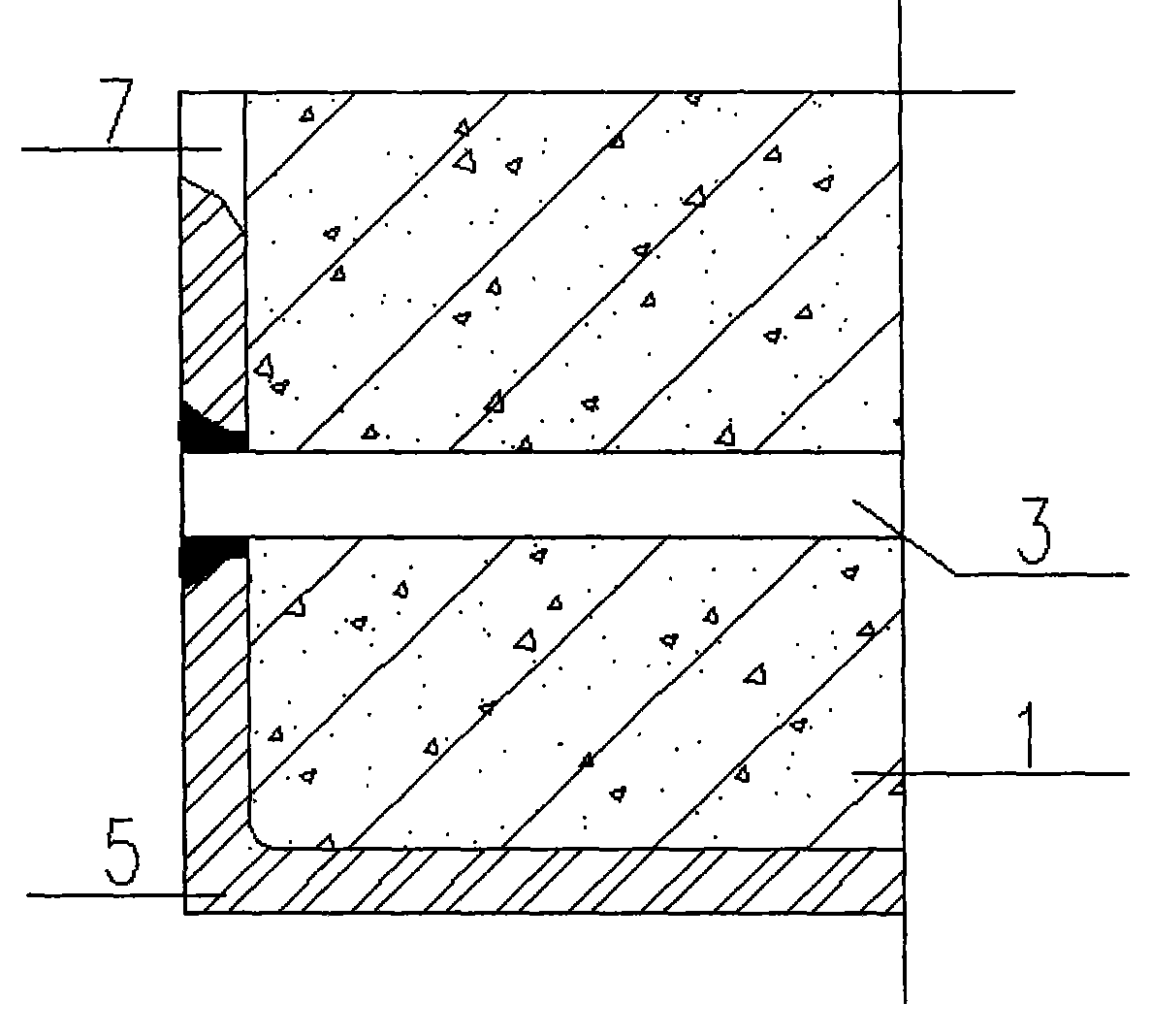

[0031] A reinforcement structure with openings behind the shear wall, see Figure 1 to Figure 5 shown. Including the original wall 1 and the floor 2, the original wall 1 is provided with a rear opening 4, and also includes a steel frame for reinforcement. and the flat steel 6 are respectively fixed at the rear opening 4 by anchor bolts 8 and through-plate high-strength bolts 10 (such as figure 1 shown). Wherein, angle steel 5 comprises the angle steel 5 that is arranged on both sides and top side of rear opening 4, and the angle steel 5 on every side is two rows, is arranged in original wall body 1 inside and outside both sides respectively (such as figure 2 shown). The vertical and horizontal junctions of the angle steel 5 on both sides and the top side of the rear opening 4 are welded to each other, and the long limbs of the angle steel 5 attached to the wall extend outward along the rear opening 4 to form an extension 12 . The angle steel 5 long limbs attached to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com