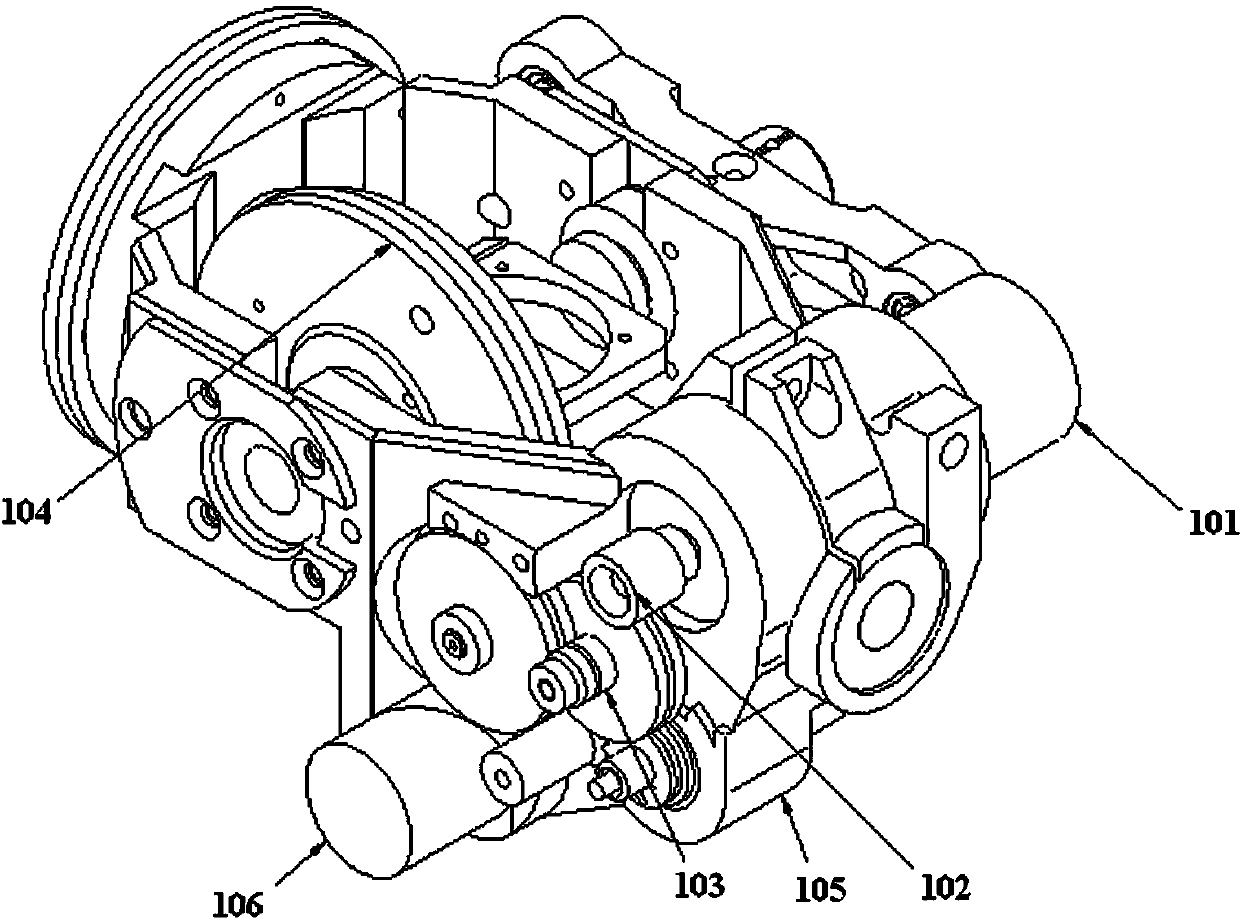

Double-gear assembly provided with backlash spring and mounting method thereof

A technology of anti-backlash springs and double-plate gears, which is applied to belts/chains/gears, hoisting devices, transmission parts, etc., can solve problems such as time-consuming, labor-intensive, lack of richness, and separation, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

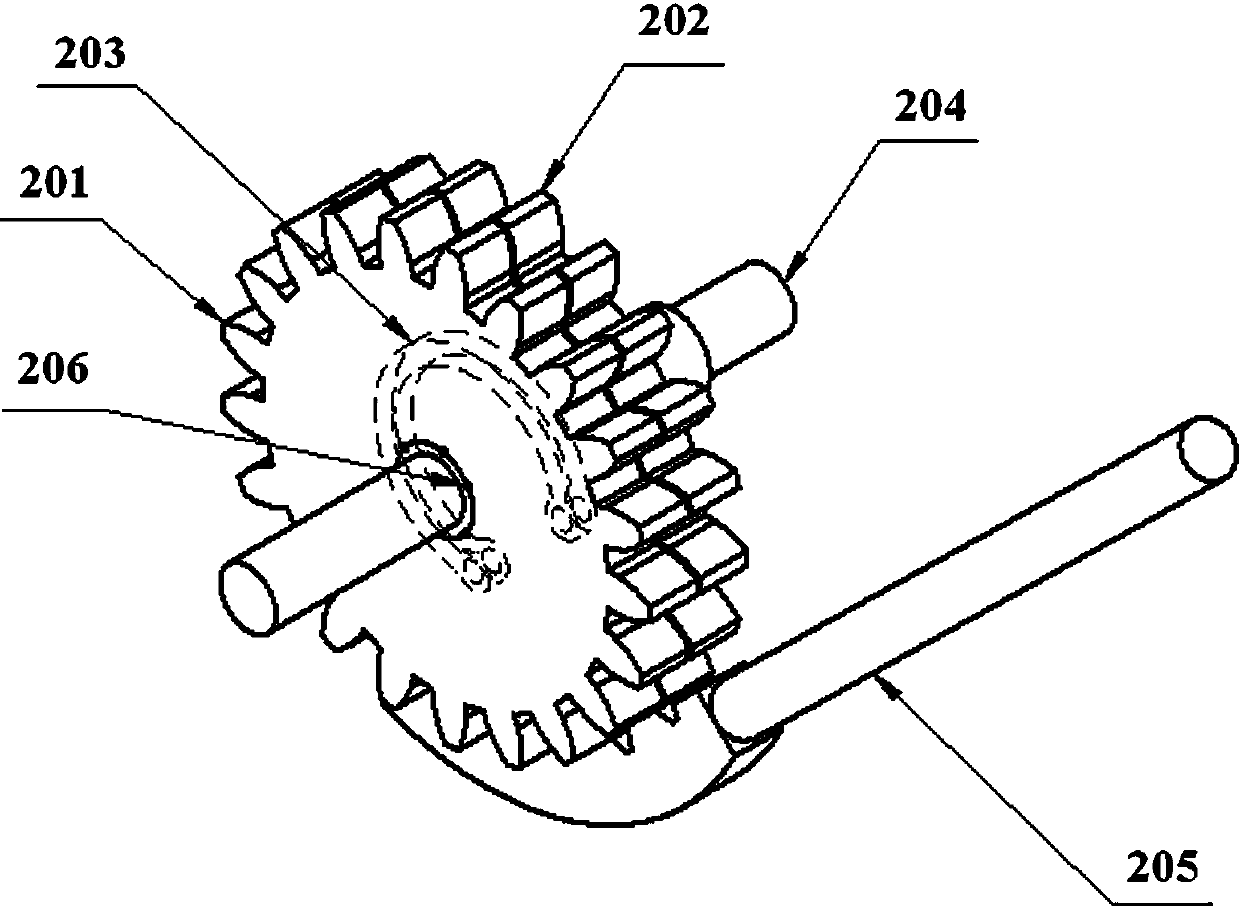

[0040] Such as Figure 4 As shown, the present invention discloses a method for installing an anti-backlash spring double-plate gear, and the method includes the following steps:

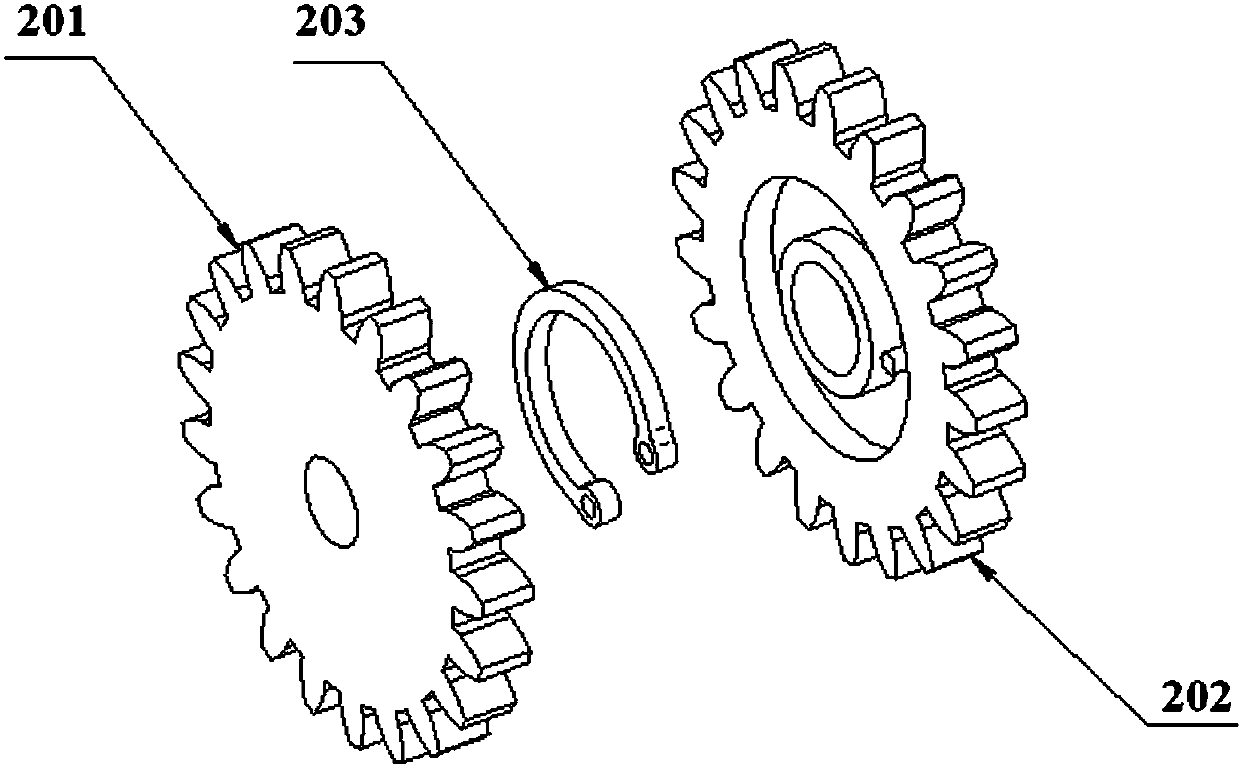

[0041] Step 1. Prefabricate pin holes on the first gear and the second gear respectively, and the pin holes of the first gear and the second gear are respectively located on circles with the same diameter centered on their centers. The requirement for the preparation of the pin hole is that when the first gear and the second gear are in a state where a certain tooth profile overlaps, the pin holes on the first gear and the second gear also coincide accordingly.

[0042] In this embodiment, the first gear and the second gear are respectively provided with through holes with equal diameters of 3.2 as pin holes on a circle with the center as the center and a diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com