Automobile headlamp optical system

A lighting and automotive technology, applied in the field of automotive headlight lighting systems, can solve the problems of narrow light width, dark light, low light utilization rate, etc., to improve the utilization rate of luminous flux, enhance light brightness, and light distribution effects. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

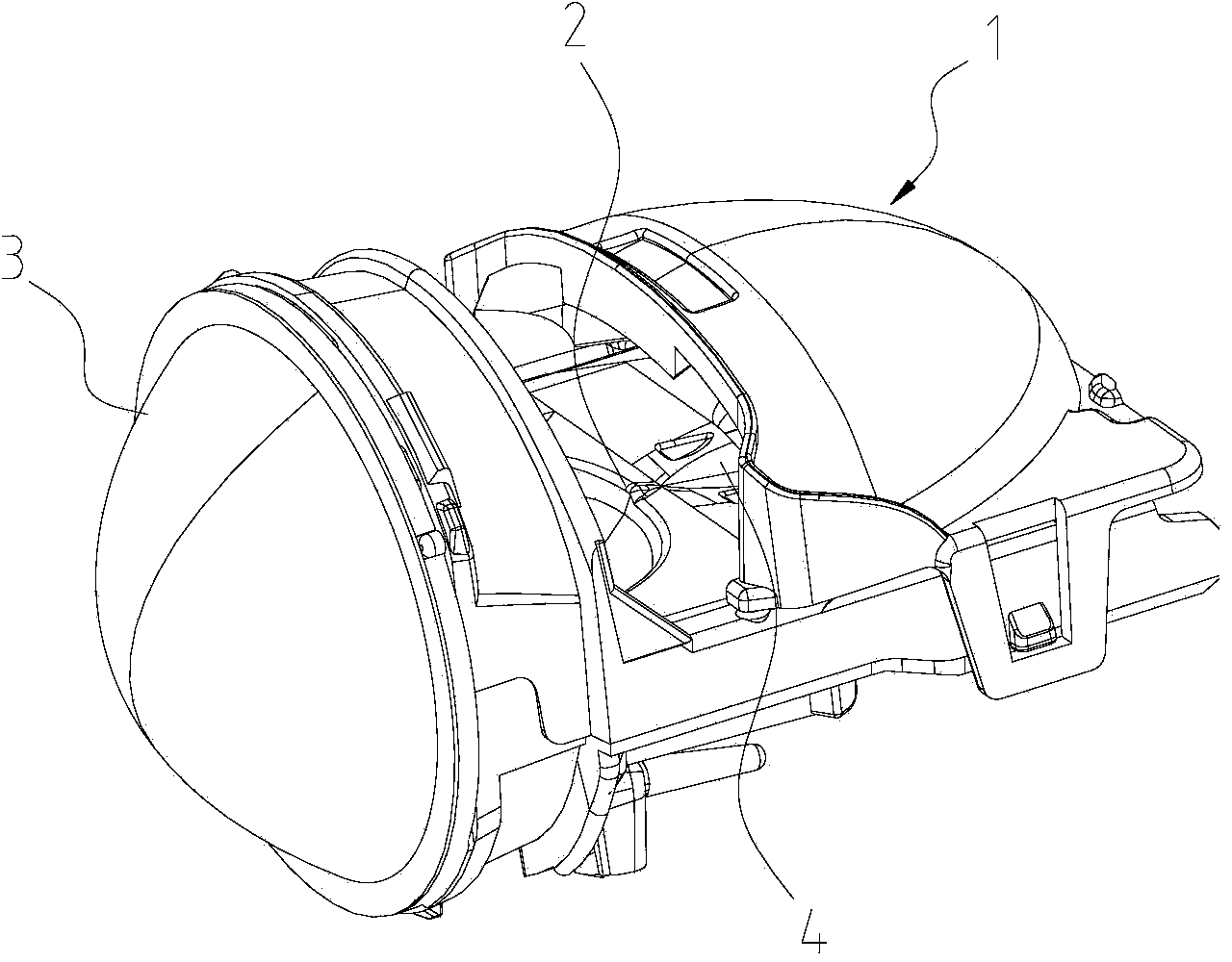

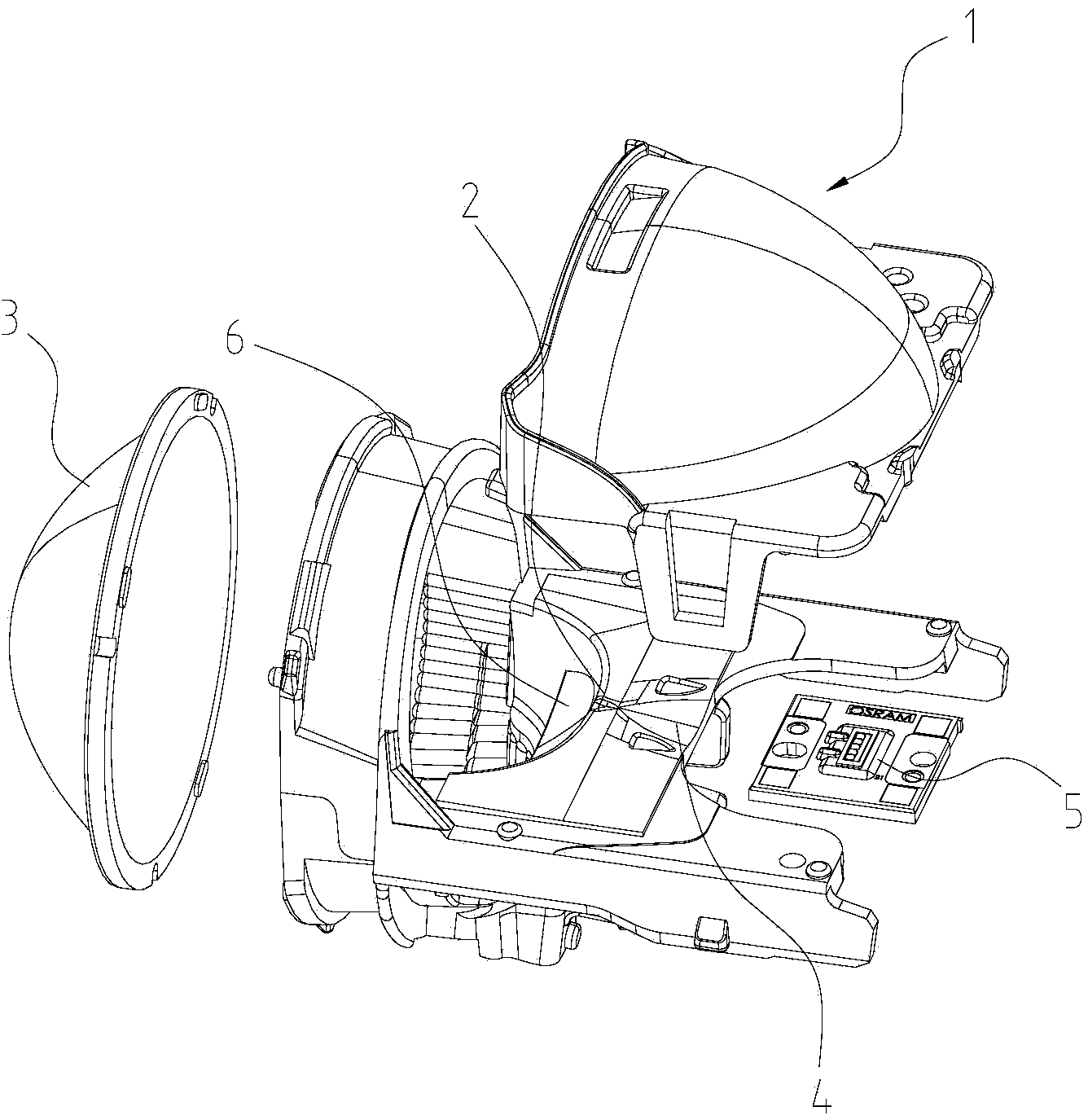

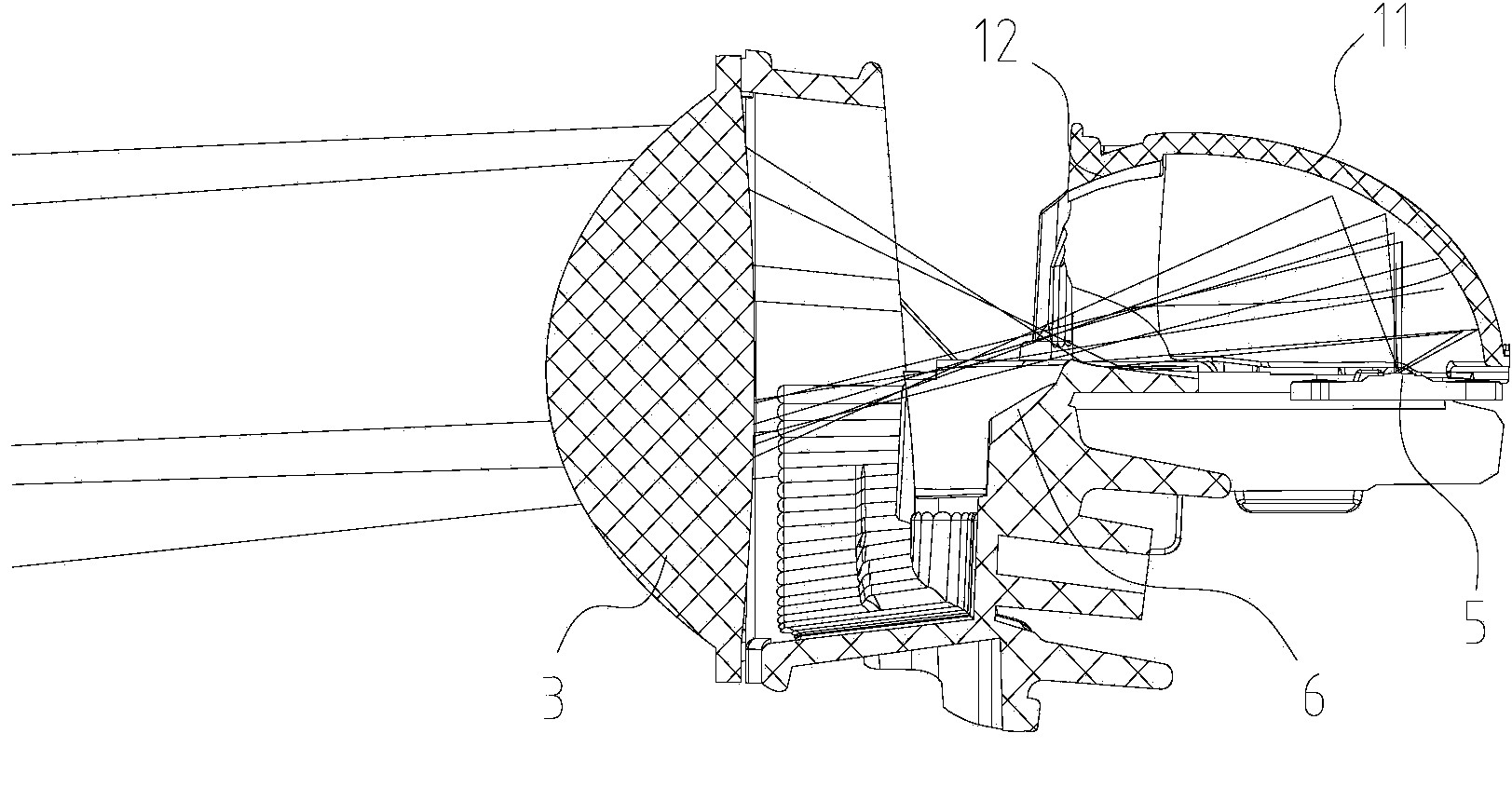

[0035] Such as Figures 1 to 3 As shown, an automotive headlight optical system includes an LED light source 5, a reflective part and a lens 3, and the reflective part includes a first reflector 1 positioned above the LED light source 5 and a reflector plate positioned below the first reflector 1 4. The baffle 2 located in front of the reflector 4 and the second reflector 6 located under the front of the baffle 2; the first reflector 1 includes a first main reflector 11 that converges and reflects light from the LED light source 5 to the lens 3 And the light from the LED light source 5 is converged and reflected to the second reflector 6 and then reflected to the first auxiliary reflector 12 of the lens 3; the part of the light blocked by the baffle 2 is reflected to the lens twice through the reflector 4 behind the baffle 2 3. To obtain the low bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com