Full-automatic combustion control device for boilers

A control device and fully automatic technology, which is applied in the direction of combustion method, combustion control, and fuel supply adjustment, can solve the problems that the boiler combustion efficiency may not be optimal, the accuracy of adjustment needs to be verified, and waste of manpower, etc., to achieve The effect of simple structure, convenient operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

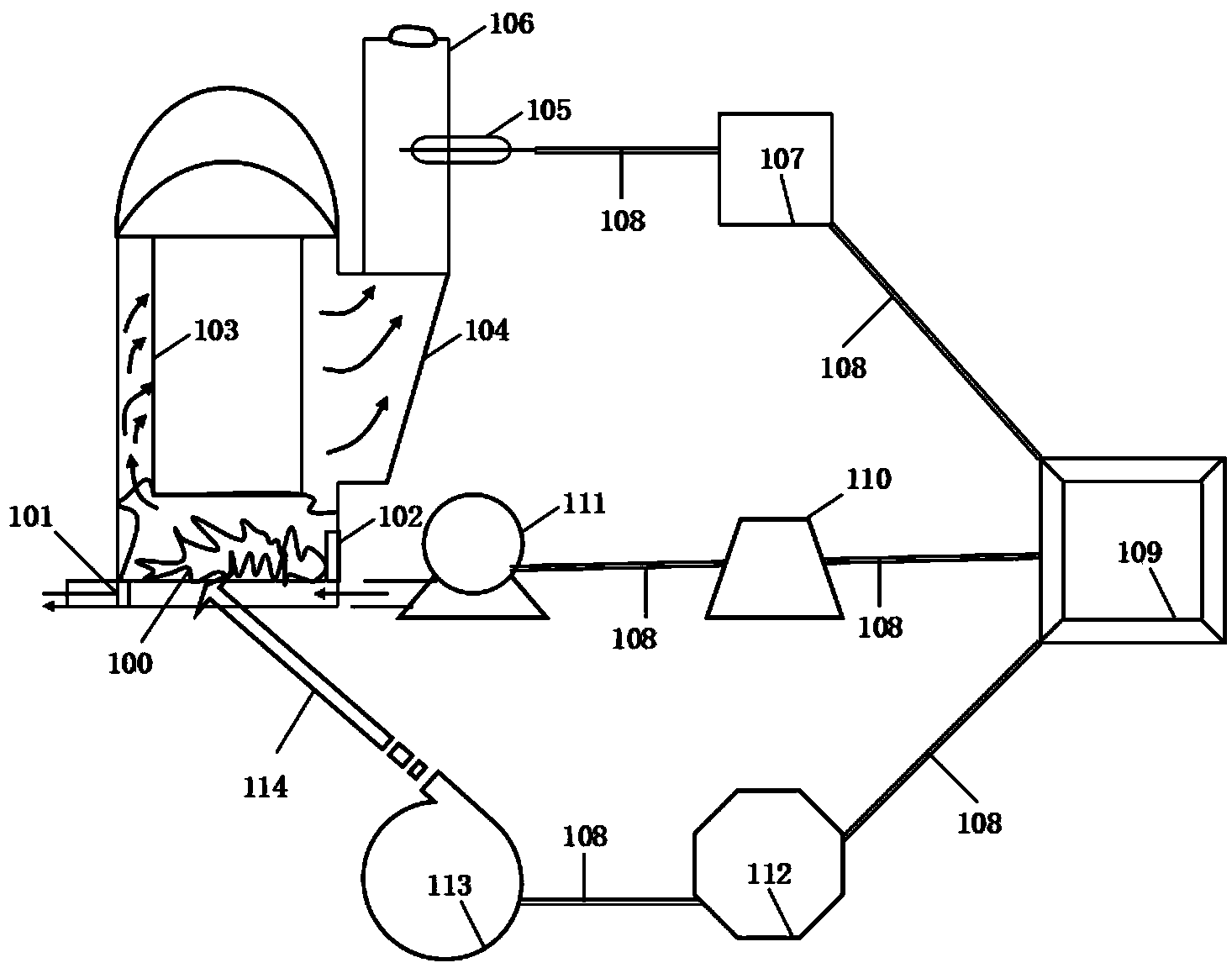

[0020] A fully automatic combustion control device for a boiler, its structure schematic diagram is as follows figure 1 As shown, 100, furnace (combustion chamber); 101, slag outlet; 102, furnace door (vent); 103, drum; 104, furnace wall; 105, CO / CO 2 Content detector; 106, chimney; 107, CO / CO 2 Content setting and acquisition instrument; 108, data transmission wire; 109, computer control center; 110, ventilation adjustment device; 111, mechanical ventilator; 112, fuel addition adjustment device; 113, combustion addition device; 114, fuel transmission belt.

[0021] The core part of the device includes CO / CO in the chimney 2 Content detector 105, CO / CO 2 Content setting and acquisition instrument 107, computer control center 109, fuel addition adjustment device 112, fuel addition device 113, mechanical ventilator 111 and its ventilation adjustment device 110.

[0022] CO / CO 2 The content detector 105 adopts Testo testo350Pro analytical instrument, the temperature resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com