Baffles and Welded Plate Heat Exchangers

A technology of baffles and components, which is applied in the field of welded plate heat exchangers, can solve the problems of complicated baffle operation process, affecting the heat exchange effect of the heat exchanger, and fluid not participating in heat exchange, so as to eliminate the existence of welded structures The effect of reducing the risk, convenient and quick assembly, and improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

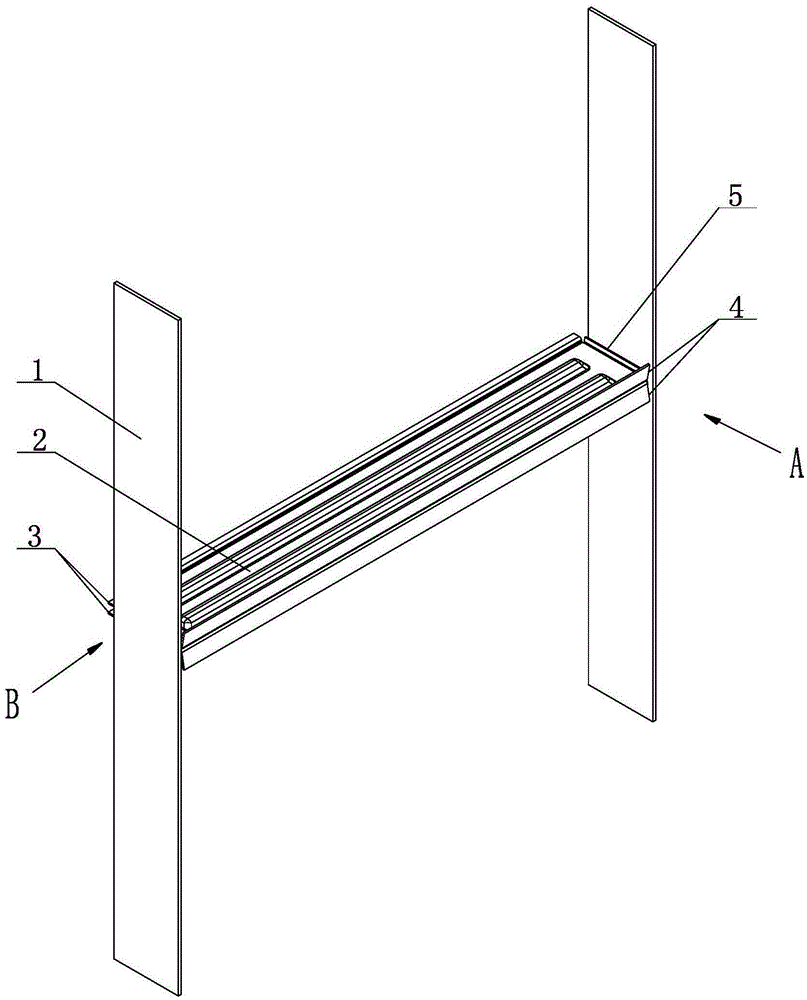

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

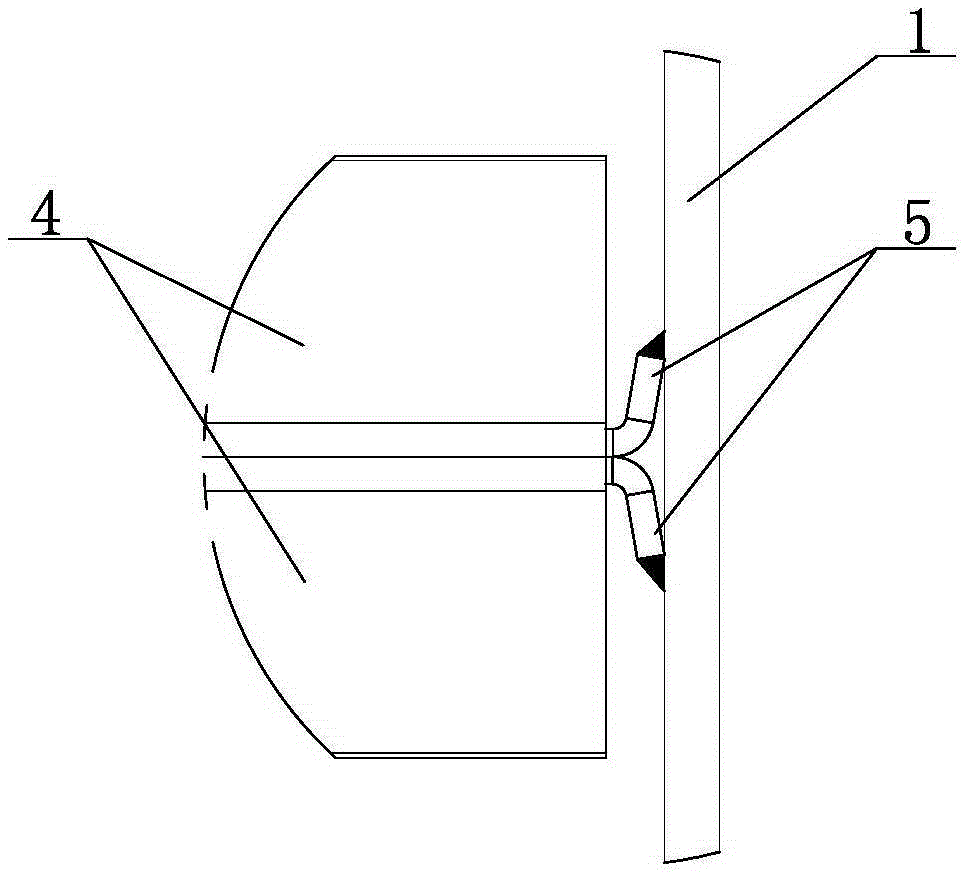

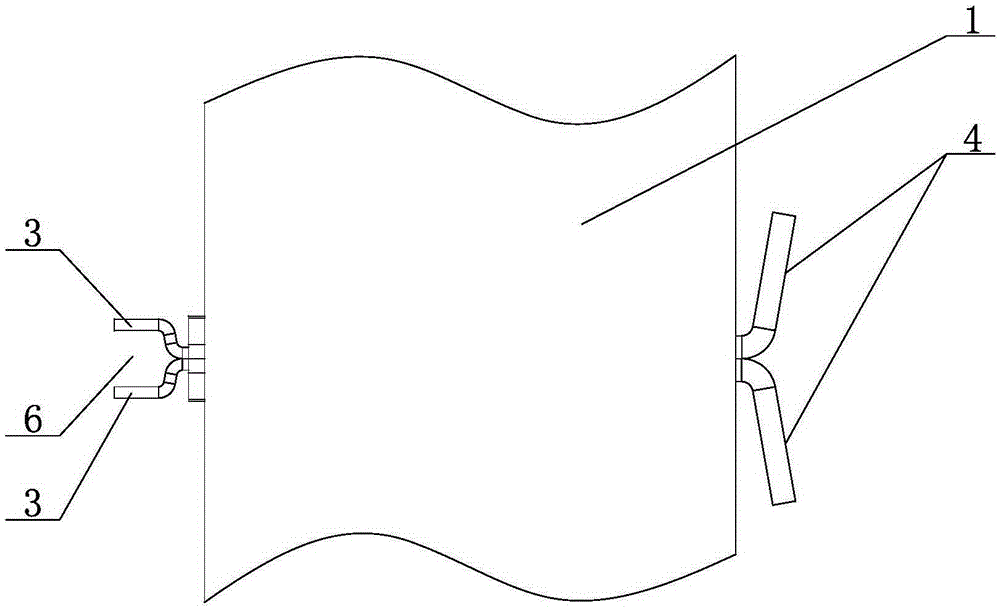

[0019] Such as Figure 1~3 As shown, the baffle assembly is composed of a baffle plate and two side plates 1. The baffle plate is welded by two corrugated plates 2 crest-to-peak (back-to-back), and the four sides of the corrugated plate 2 have hems. The side panels 1 are welded to the flanges 5 on the left and right sides of the two corrugated plates in the baffle respectively, the side plate 1 is perpendicular to the baffle, and the flanges 3 on the rear side of the two corrugated plates jointly form a bayonet 6.

[0020] In this baffle assembly, after the two corrugated plates are welded together, the shape of the bayonet 6 formed by the combination of the folded edges 3 on the rear side of the two corrugated plates matches the shape of the flow channel 15 on the side of the plate, so that it can be clamped on the Above the flow channel 15 on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com