Method and device for determining radon gas separation in load coal fracture process

A method of determination and coal-loaded technology, which is applied in fuel oil testing, material inspection products, etc., can solve problems in the preliminary test stage, and achieve the effects of improving test sensitivity, adjustable and controllable carrier gas, and rapid and accurate determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

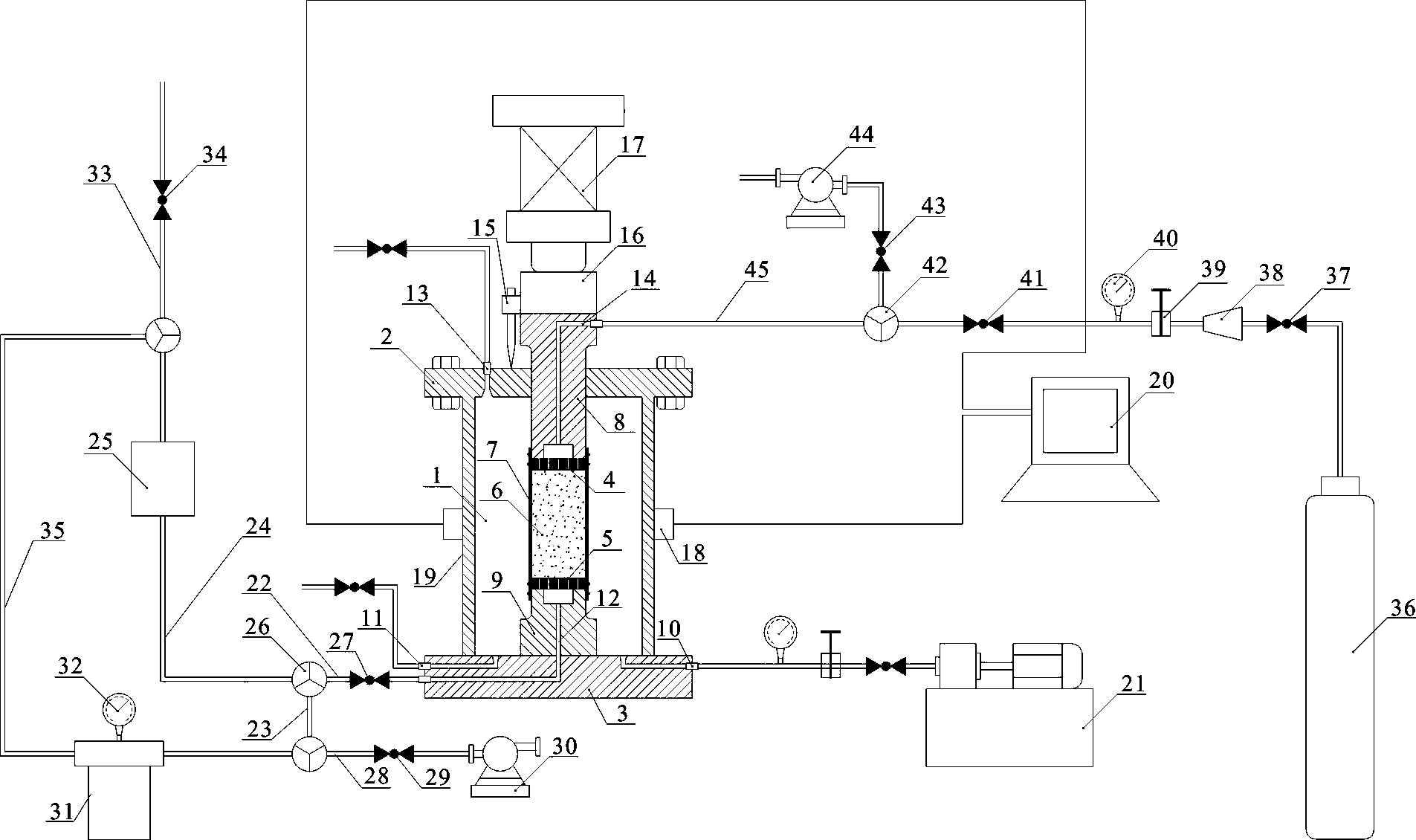

[0027] Measuring device for radon gas release during the fracture process of loaded coal, such as figure 1 As shown, it includes a three-axis compression instrument. The three-axis compression instrument includes a pressure chamber 1 and a hydraulic cylinder 17 arranged above the pressure chamber 1. Side plate 19 forms. The pressure chamber 1 is provided with an upper pressure head 8, a lower pressure head 9 and a heat-shrinkable tube 7 vertically arranged between the upper pressure head 8 and the lower pressure head 9, and the upper pressure head 8, the lower pressure head 9 and the heat-shrinkable tube 7 together form a sample chamber; the lower part of the upper pressing head 8 is provided with a porous plate 4, and the upper part of the lower pressing head 9 is provided with a porous plate 5. The upper pressing head 8 protrudes upwards outside the top plate 2, and the hydraulic rod of the hydraulic cylinder 17 extends downwards and connects the top of the upper pressing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com