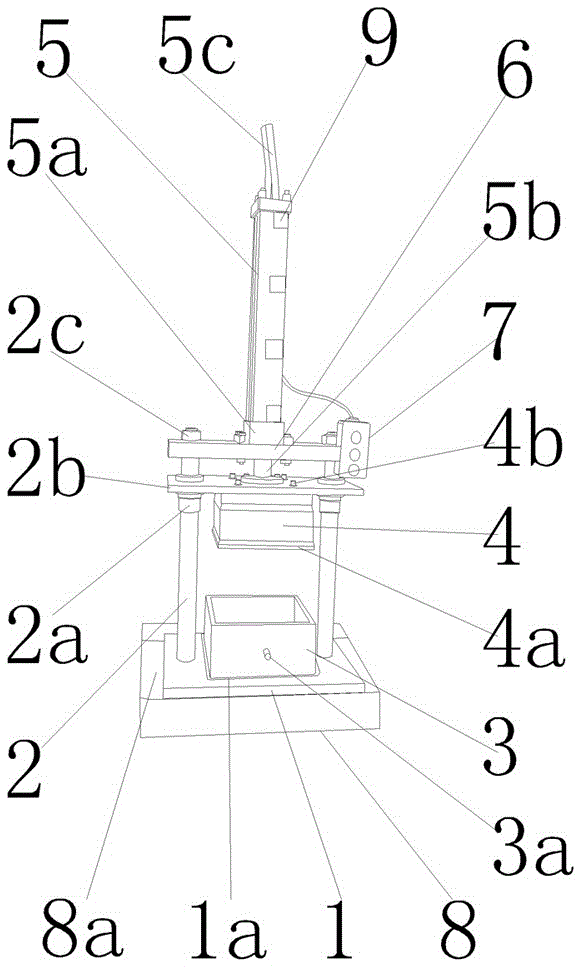

An automatic monitoring extrusion molding machine

An automatic monitoring and forming machine technology, applied in the field of food processing, can solve problems such as lack, and achieve the effect of large internal extrusion force, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description is merely exemplary in nature and in no way is intended to limit the invention, its application or uses. For the sake of clarity, corresponding reference numbers will be used in the drawings to designate like elements. As used herein, the phrase "at least one of A, B, and C" should be construed to mean logically A or B or C using a non-exclusive logical "or". It should be understood that various steps within a method may be executed in different order without altering the principles of the present invention.

[0032] The change of the specific shape by the designer according to the specific requirements should not be regarded as departing from the essence of the present invention.

[0033] Examples of the present disclosure will now be described more fully with reference to the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses.

[0034] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com