Method for regenerating deactivated palladium catalyst on line in process of preparing ethylene glycol through coal

A coal-to-ethylene glycol and palladium catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve cumbersome process, low cost, and non-environmental protection and other problems, to achieve the effect of low activation temperature, low cost, and solve the problem of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

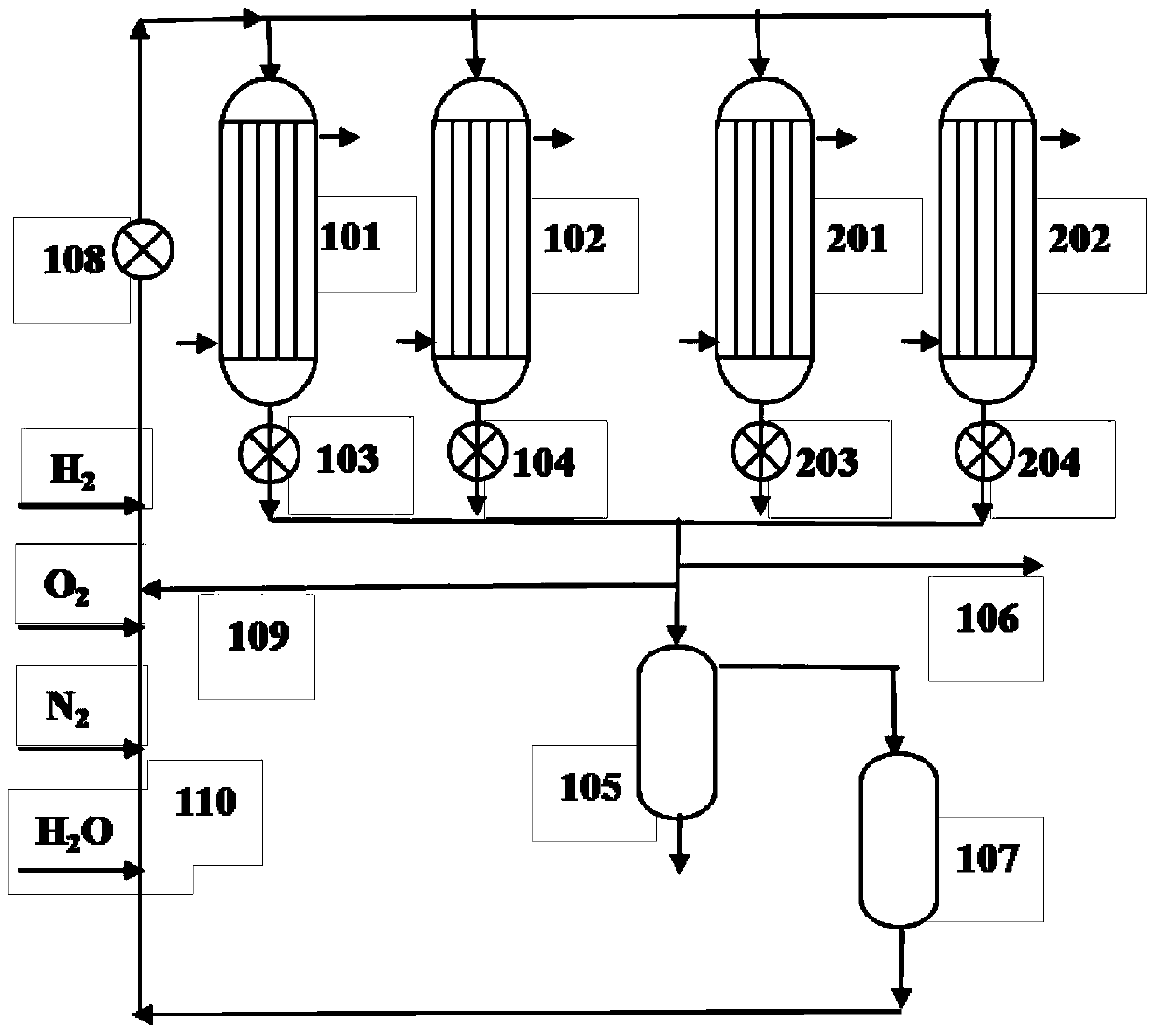

[0029] exist figure 1 In the shown coal-to-ethylene glycol plant, the palladium catalysts in the dehydrogenation reactors 101 and 102 and the synthesis reactors 201 and 202 are simultaneously regenerated.

[0030] Before regeneration, close the reaction gas first, stop the operation of the coal-to-ethylene glycol unit, and feed N through the regeneration gas inlet of 110 2 , cool down to room temperature, purge the reactor and the regeneration pipeline, turn on the circulation compressor and the venting device, and control the venting volume at 10%. After 6h, the CO content in the circulating gas is 0.95%, and the gas replacement is completed. Gradually raise the temperature of 101 and 102 to 120°C, gradually raise the temperature of 201 and 202 to 150°C, pass water vapor from 110 to replace N 2 , the venting amount is controlled at 5%, after 3h, the water vapor content in the circulating gas is 70%, and the space velocity is 3000h -1 , Continuous reaction for 20h to remove ...

Embodiment 2

[0035] exist figure 1 In the coal-to-ethylene glycol unit shown, the palladium catalysts in dehydrogenation reactors 101 and 102 are regenerated separately.

[0036] Refer to Example 1 for the gas path control and replacement process of the regeneration process. Before regeneration, first turn off the reaction gas, stop the operation of the coal-to-ethylene glycol unit, and inject N 2 , cool down to room temperature, purge the reactor and the regeneration pipeline, and complete the gas replacement after 3 hours, gradually raise the temperature of 101 and 102 to 130°C, pass in water vapor to remove some organic and inorganic substances attached to the catalyst surface, and the space velocity is 1000h -1 , after continuous reaction for 12h, N 2 Replace the water vapor, then raise the temperature of 101 and 102 to 300°C, and the space velocity is 2000h -1 Constant temperature for 24h, dredge the carrier channel, after that, use O 2 to N 2 Carry out replacement, and raise th...

Embodiment 3

[0038] exist figure 1 In the coal-to-ethylene glycol unit shown, the palladium catalysts in synthesis reactors 201 and 202 are regenerated separately.

[0039] Refer to Example 1 for the gas path control and replacement process of the regeneration process. Before regeneration, first turn off the reaction gas, stop the operation of the coal-to-ethylene glycol unit, and inject N 2 , cool down to room temperature, purge the reactor and the regeneration pipeline, complete the gas replacement after 8 hours, gradually raise the temperature of 201 and 202 to 150°C, pass in water vapor to remove some organic and inorganic substances attached to the surface of the catalyst, and the space velocity is 3000h -1 , after continuous reaction for 20h, N 2 Replace the water vapor, then raise the temperature of 201 and 202 to 350°C, and the space velocity is 4000h -1 Constant temperature for 30h, dredge the carrier channel, after that, use O 2 to N 2 Carry out replacement, and raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com