Anti-refluxing sealing test tube cap

A test tube cover and anti-reflux technology, applied in the field of laboratory equipment, can solve the problems of reduced sealing, ejection, and external air pressure difference, and achieve the effects of being conducive to popularization and application, convenient production and use, and good use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

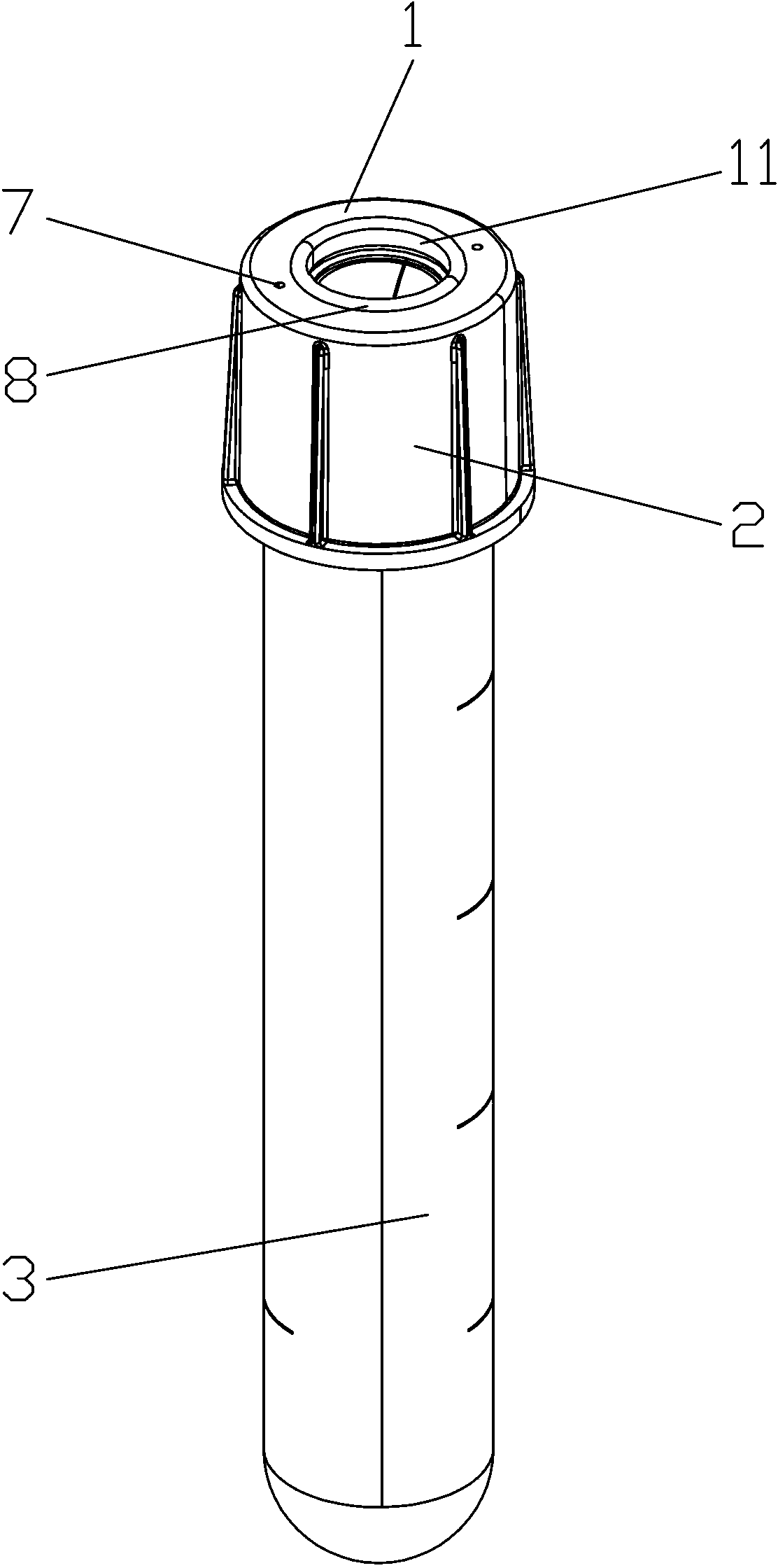

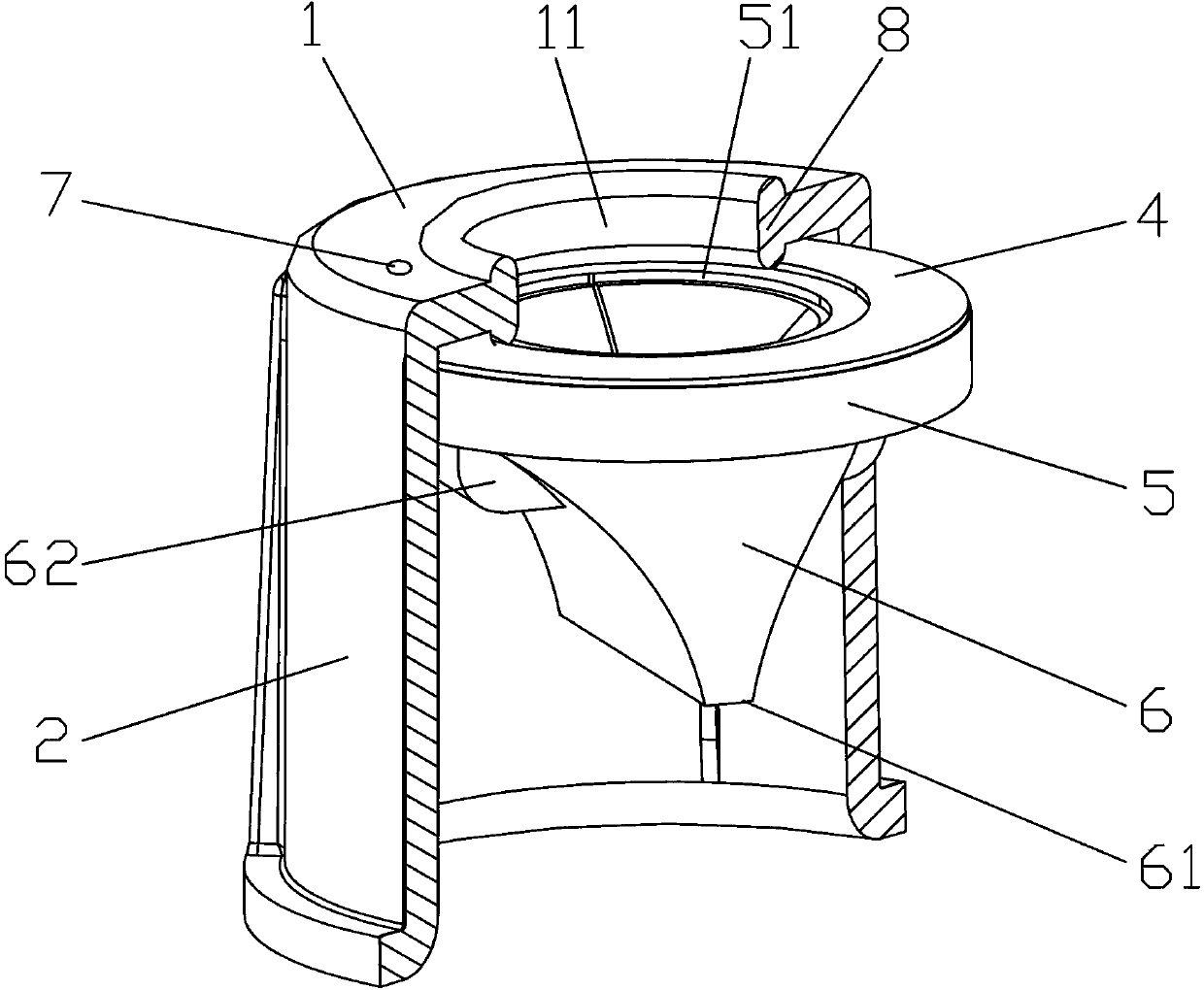

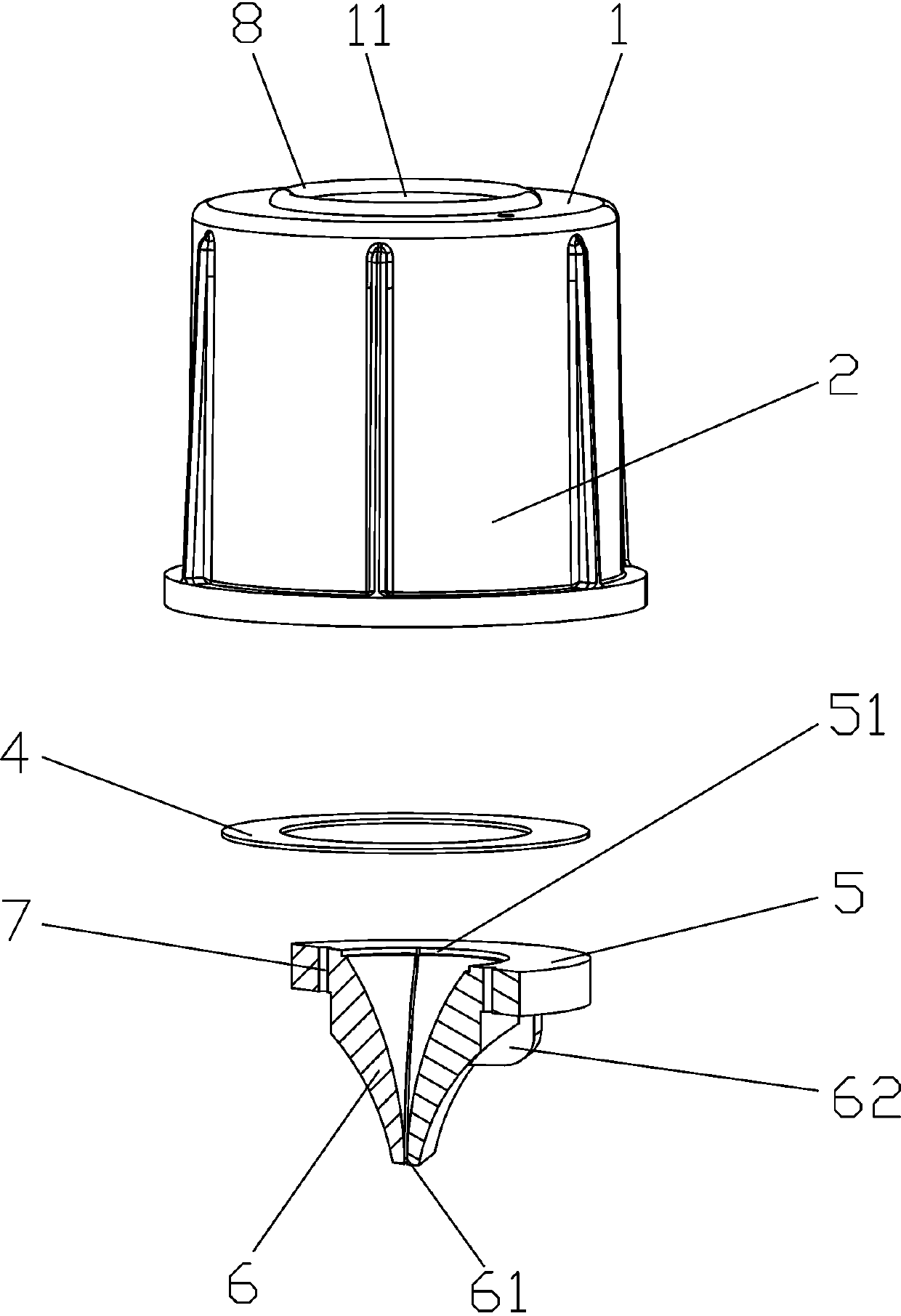

[0015] refer to figure 1 , figure 2 , image 3 , a sealed anti-reflux test tube cover, comprising a top cover 1 and a cylindrical cover body 2, wherein the size and shape of the cover body 2 matches the test tube opening of the test tube 3, and the top cover 1 and the cover body 2 are test tube covers The main body is generally made of plastic or other relatively soft materials. There is a through hole 11 in the top cover 1, and the lower end of the top cover 1 is provided with a microporous membrane ring 4 and a check valve ring 5 in sequence, wherein the middle of the check valve ring 5 is provided with a downward facing The duckbill valve port 6, the lower end of the duckbill valve port 6 is folded toward the middle to form a flat mouth 61, wherein the check valve ring 5 and the duckbill valve port 6 are integrated into a duckbill mechanism. The duckbill mechanism, especially the duckbill valve port 6, is generally made of rubber to ensure that the flat mouth 61 is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com