Check valve sand supply device of sand ejector

A one-way valve, sand shooting machine technology, applied in molding machines, casting molding equipment, metal processing equipment and other directions, can solve the problems of easy spring fatigue, damage replacement, low failure rate, etc., to avoid movement skew, accurate reset, The effect of low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

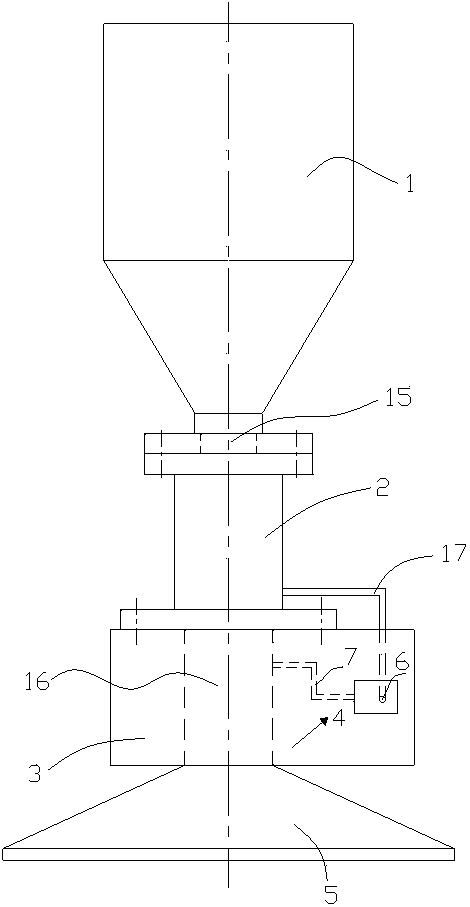

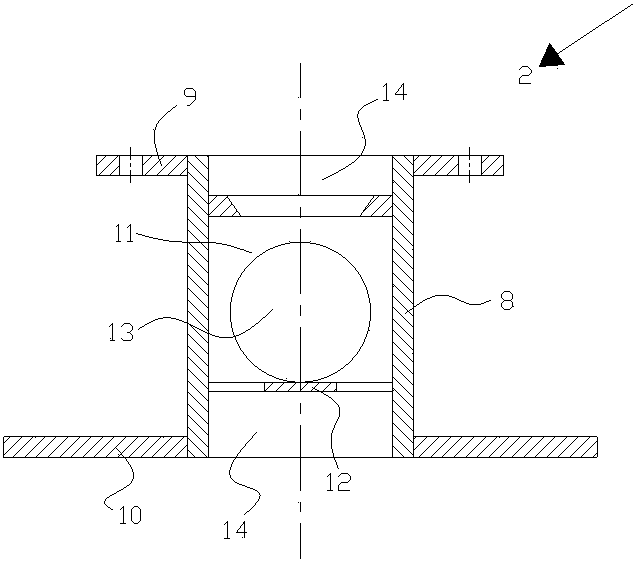

[0011] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

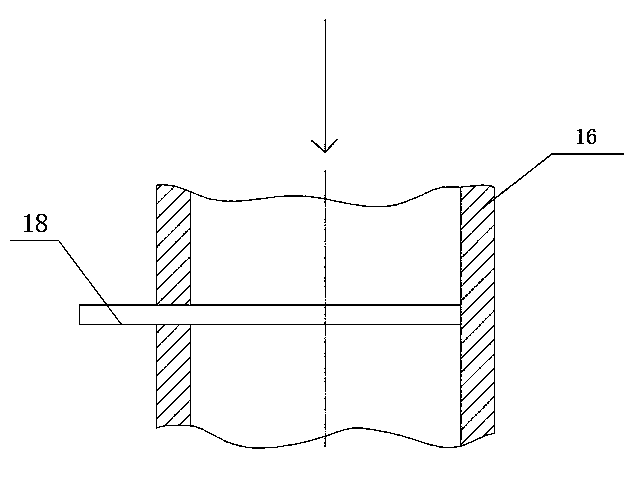

[0012] Such as figure 2 , 3 As shown, a one-way valve sand supply device for a sand shooting machine includes a sand bucket 1, a sand-adding one-way valve 2, a box body 3, a pneumatic device 4 and an iron box 5, and the pneumatic device 4 includes a pneumatic switch 6, The first air delivery pipe 7 and the second air delivery pipe 17, the sand adding one-way valve 2 includes a valve body 8 and an upper valve seat 9 and a lower valve seat 10 connected to the upper and lower ends of the valve body 8 respectively. A hollow valve cavity 11 is provided in the valve body 8, and a limiting plate 12 is arranged in the valve cavity 11, and a movable circular ball valve 13 is arranged on the limiting plate 12, wherein, the upper valve seat 9, the lower valve seat The central part of the seat 10 is respectively provided with quicksand holes 14, and the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com