A gas turbine power turbine guide vane datum plane positioning processing method

A technology for power turbines and gas turbines, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of inconsistency in the assembly and positioning of steam passages and steam passage arcs, damage to the steam passages, and failure to ensure blade roots and blade tops Problems such as the accuracy of the steam outlet plane drop and the arc arc of the steam channel have achieved the effects of stable processing, improved efficiency, and improved geometric accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

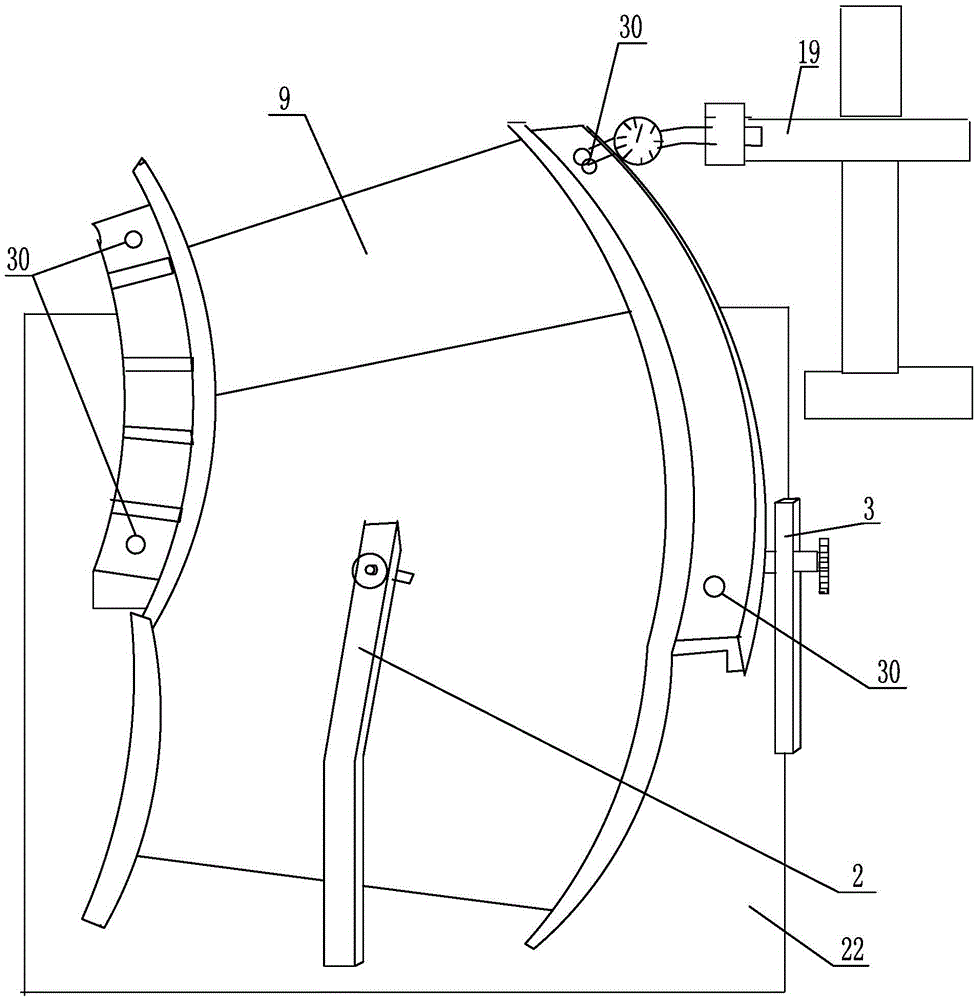

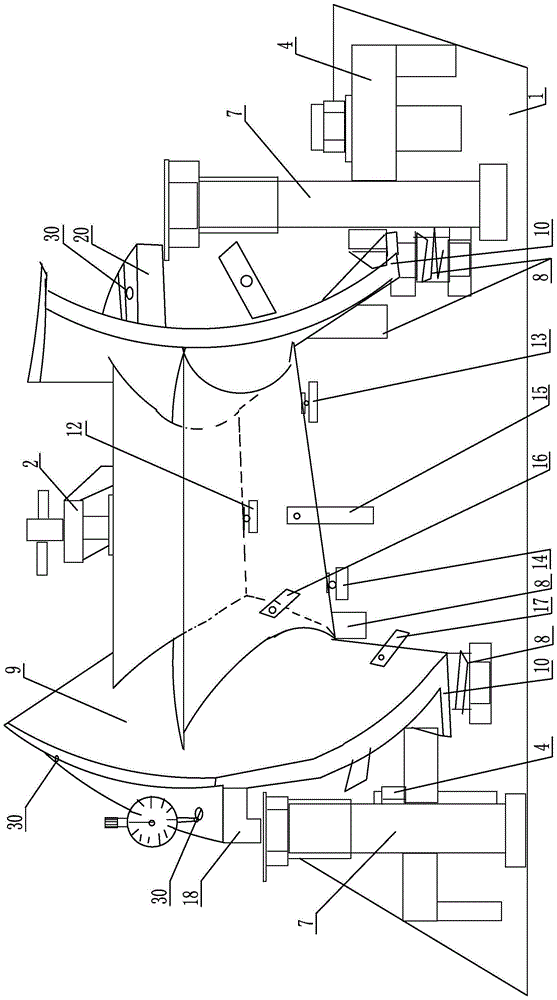

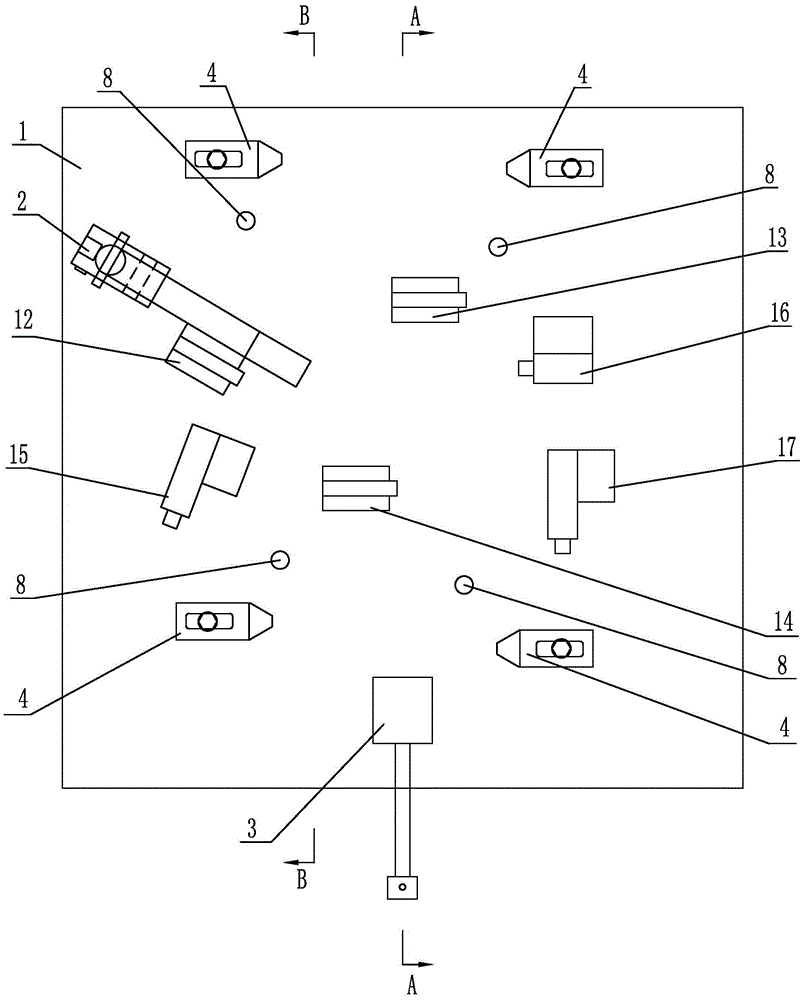

[0017] Specific implementation mode one: combine Figure 1-Figure 6 Explain that a gas turbine power turbine guide vane datum plane positioning processing method of the present embodiment is carried out according to the following steps:

[0018] Step 1, using a measuring tool to find four points 30 on the blade root surface of the gas turbine power turbine guide vane blank 9, and measure the size between the four points, and the drop of the four points relative to the same reference plane;

[0019] Step 2, measure the size of the margin of the arc on the steam outlet side of the gas turbine power turbine guide vane blank 9, and make a record;

[0020] Step 3: Put the blank 9 of the guide vane of the gas turbine power turbine on the clamping and positioning device, and use a feeler gauge to measure the first positioning seat 12, the second positioning seat 13, the third positioning seat 14, the fourth positioning seat 15, and the fifth positioning seat The six positioning poin...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination figure 2 and image 3 Note that in step 4 of this embodiment, the blank of the guide vane of the gas turbine power turbine is raised by 0.3mm. This setting ensures that when the guide vane is clamped during processing, the steam passage of the guide vane cannot be damaged and the steam passage is protected. Practice has proved that the thickness of 0.3mm is just enough. Others are the same as in the first embodiment.

[0037] work process

[0038] The present invention is used for precision casting guide vanes of gas turbine power turbines, mainly through measuring tools to find four points on the drop surface of the arc margin on the rough surface of the turbine guide vanes of gas turbines, and using a dial gauge to pass four points on the CNC machine tool. Point alignment and the exact position of the measuring tool, adjust the auxiliary lifting and adjusting support device to convert the benchmark, avoiding the indent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com