Parallel mechanism arm

A manipulator and parallel technology, applied in the field of manipulators, can solve the problems of the mechanism occupying a large working space, deteriorating the dynamic performance of the system, increasing the inertia of the system motion, etc., to achieve the effect of improving production efficiency, large space utilization, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

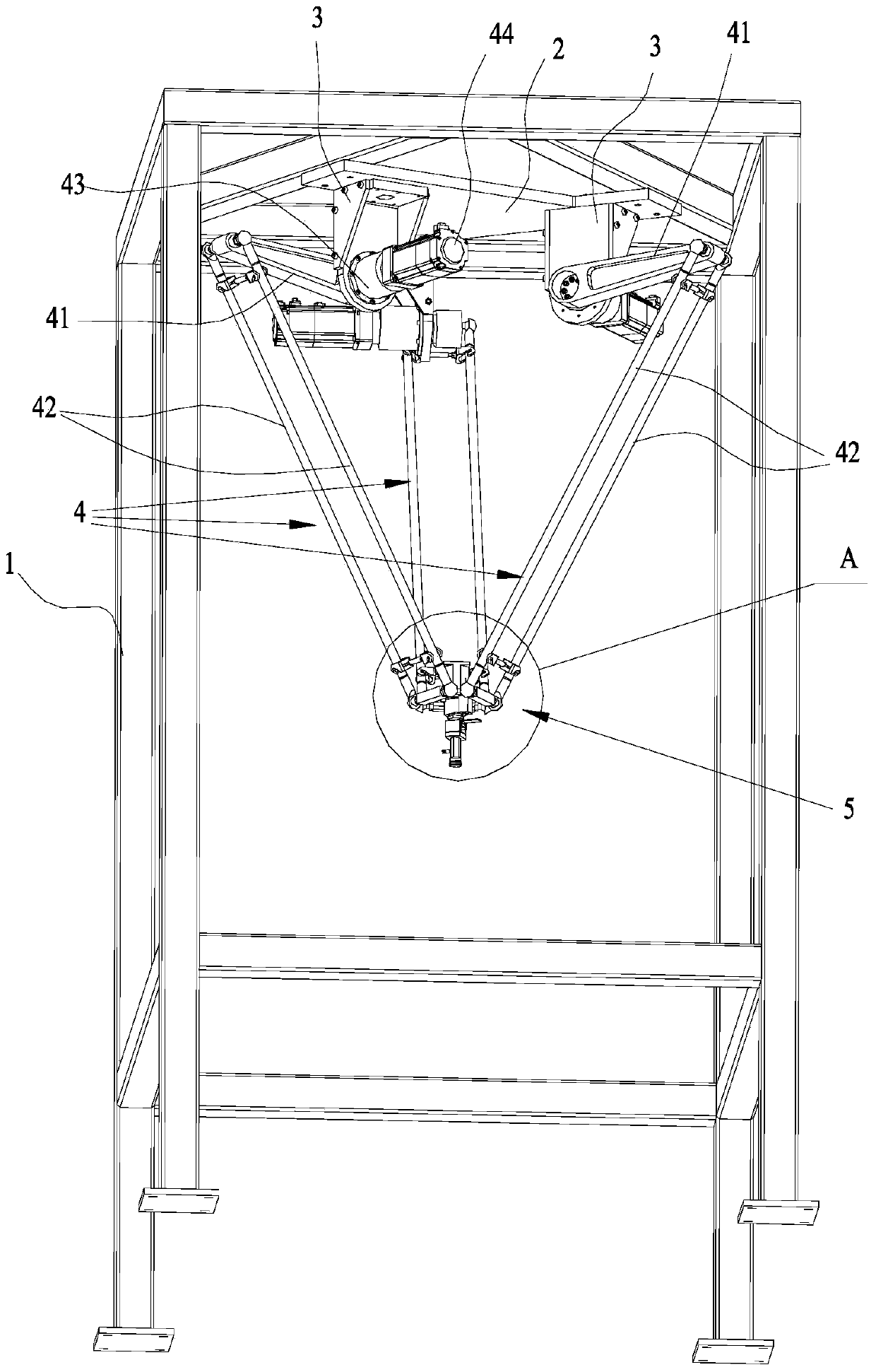

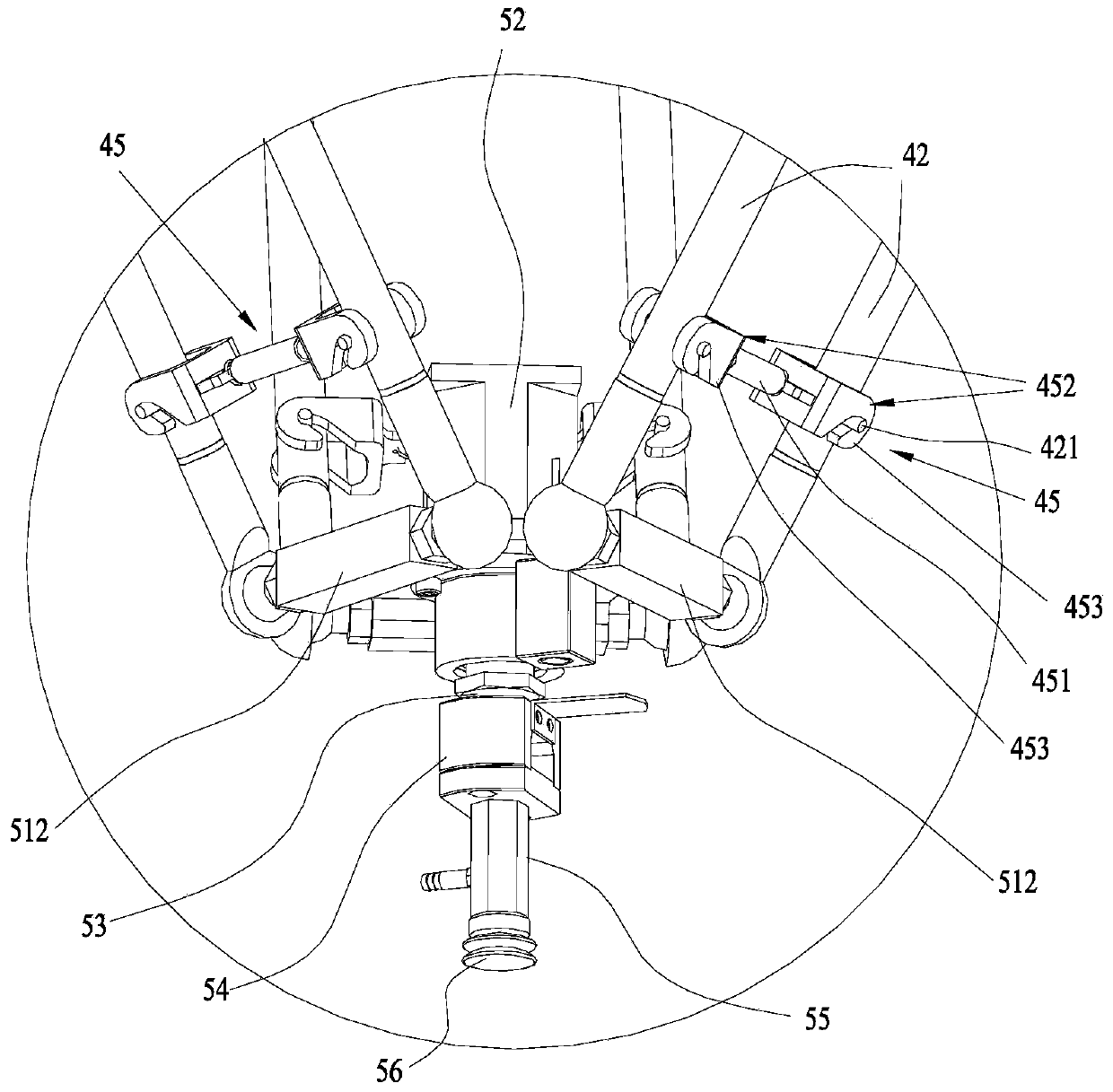

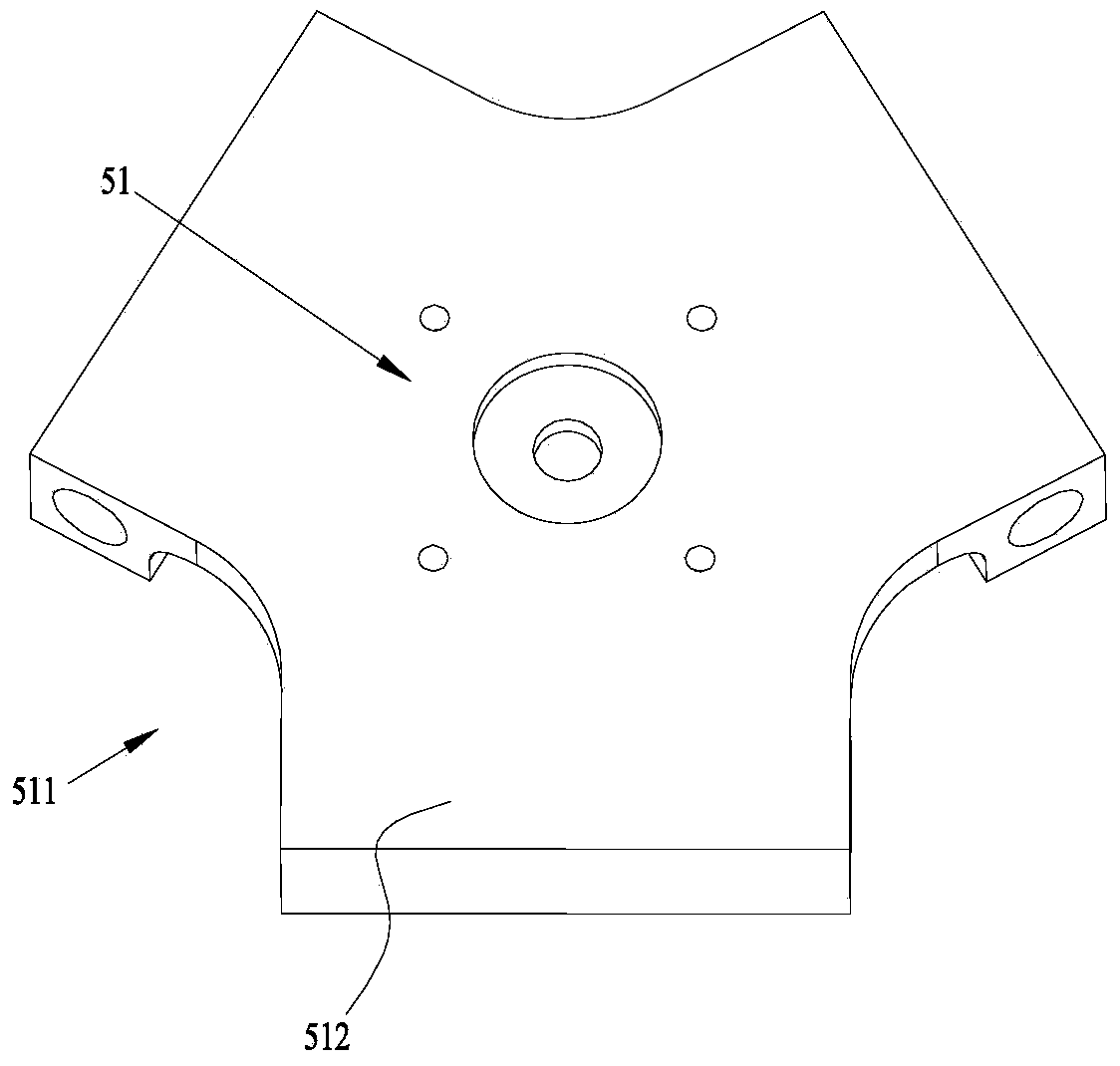

[0027] Such as figure 1 The shown parallel manipulator comprises a fixed frame 1, a horizontal plate 2, a plurality of suspension frames 3, a plurality of transmission mechanisms 4 and an adsorption device 5, the horizontal plate 2 is fixed on the top of the fixed frame 1, each suspension frame 3 One end is fixed to the horizontal plate 2 respectively, the other end of each suspension frame 3 extends vertically downward, the adsorption device 5 is located below the suspension frame 3, and each suspension frame 3 is distributed symmetrically with the vertical line axis where the center of the horizontal plate 2 is located; Each transmission mechanism 4 includes a master arm 41, a slave arm 42, a reducer 43 and a servo motor 44, the reducer 43 is fixedly connected to the lower end of the suspension frame 3, and the output shaft of the servo motor 44 is connected to the master arm 41 through the reducer 43 One end of the main arm 41 is hinged with one end of the slave arm 42, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com