Manufacturing method for composite material scaling ladder

A manufacturing method and composite material technology, which are applied in the field of fire fighting equipment research and development, can solve the problems of large overall mass of the ladder, poor strength of aluminum alloy materials, and low strength of wood, and achieve the effects of improving emergency efficiency and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

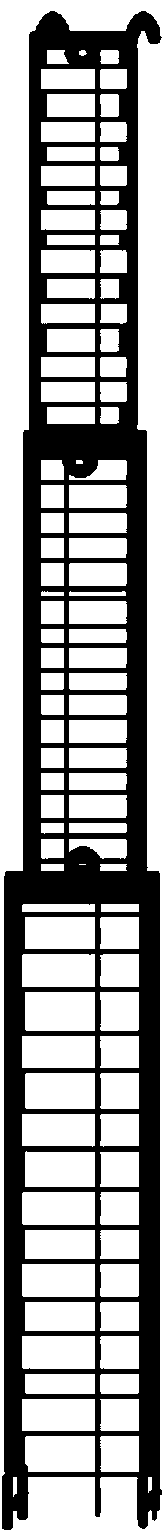

[0019] The invention provides a method for manufacturing a ladder made of composite materials, which includes the following steps: putting high-strength carbon fibers into a mold after braiding and surface treatment; putting titanium alloy or magnesium alloy or engineering plastic at a temperature of about 430-750 degrees Melt, pour the melted titanium alloy or magnesium alloy or engineering plastic into the mold; make the frame and boarding layer of the ladder.

[0020] The frame and boarding layer of the ladder are directly solidified and formed as a whole.

[0021] The frame of the ladder and the boarding are bonded together or fixedly connected by screws.

Embodiment 2

[0023] Melt titanium alloy or magnesium alloy or engineering plastic at a temperature of about 430-750 degrees, melt the titanium alloy or magnesium alloy, weave high-strength carbon fiber into cloth by warp and weft weaving, and then pre-soak it in the melted melt, and then carry out The frame and boarding layer of the ladder are made of high-temperature curing molding.

[0024] The aerial ladder of the present invention can be made into small sections connected one by one, and the sliding part of the aerial ladder can be made of graphite material with good self-lubricity, which can be positioned and slid with each other, waterproof and dustproof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com