Control method of trailer control valve

A control method and control valve technology, applied to control valves, air release valves, brakes, brake components, etc., can solve the problems of hysteresis in the transmission rate of air pressure signals, slow brake response, lengthy air pressure pipelines, etc., and achieve improved control Improve motor coordination, satisfy safety, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

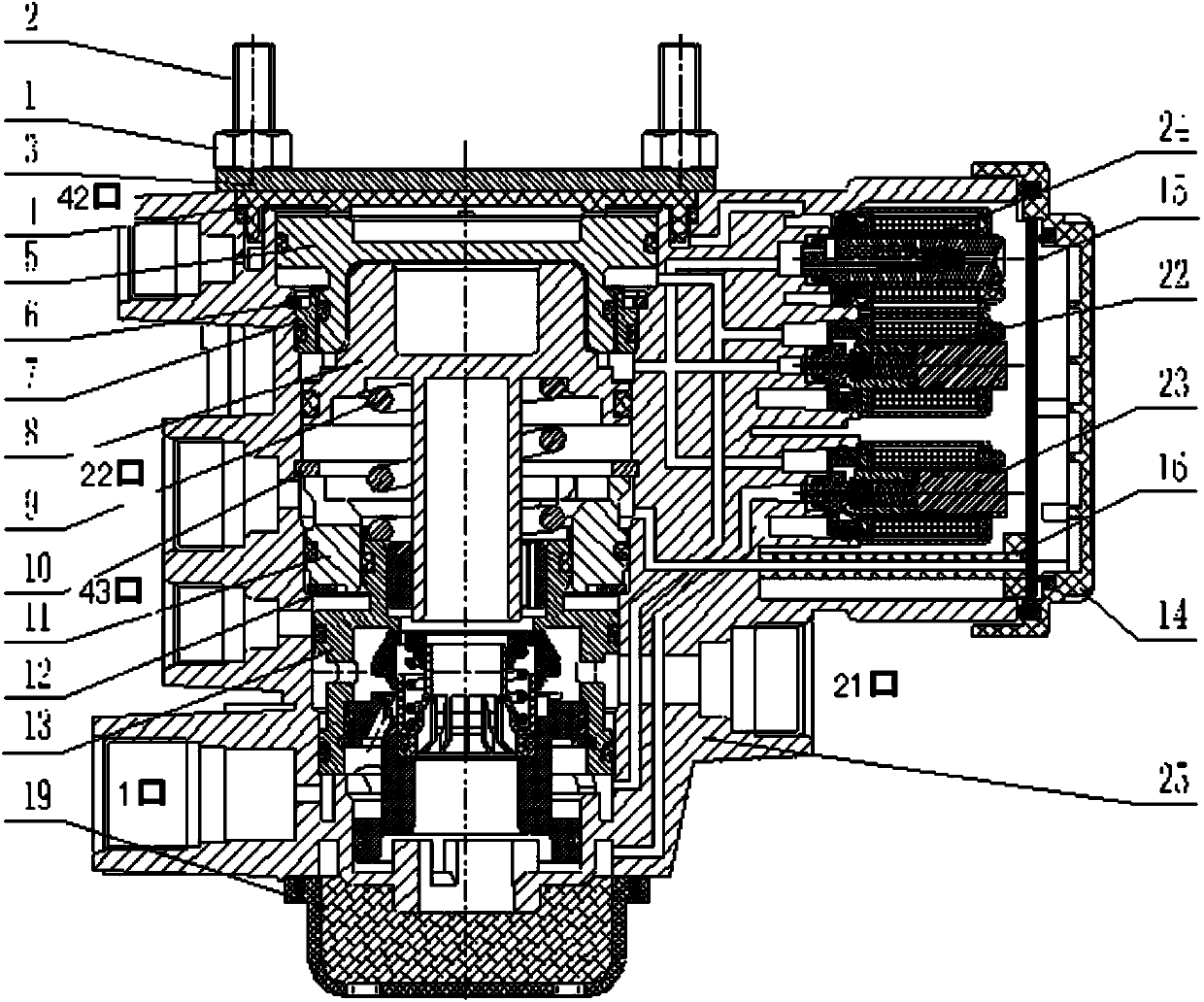

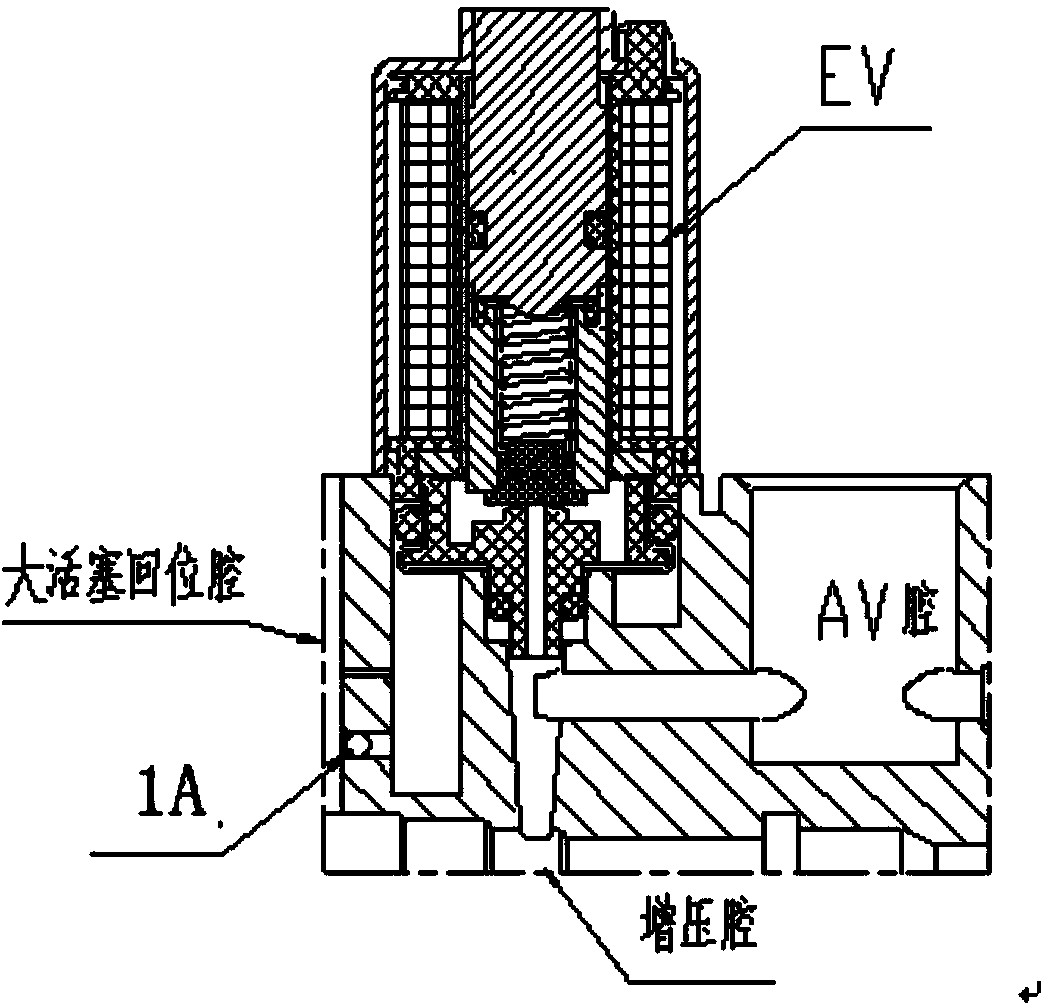

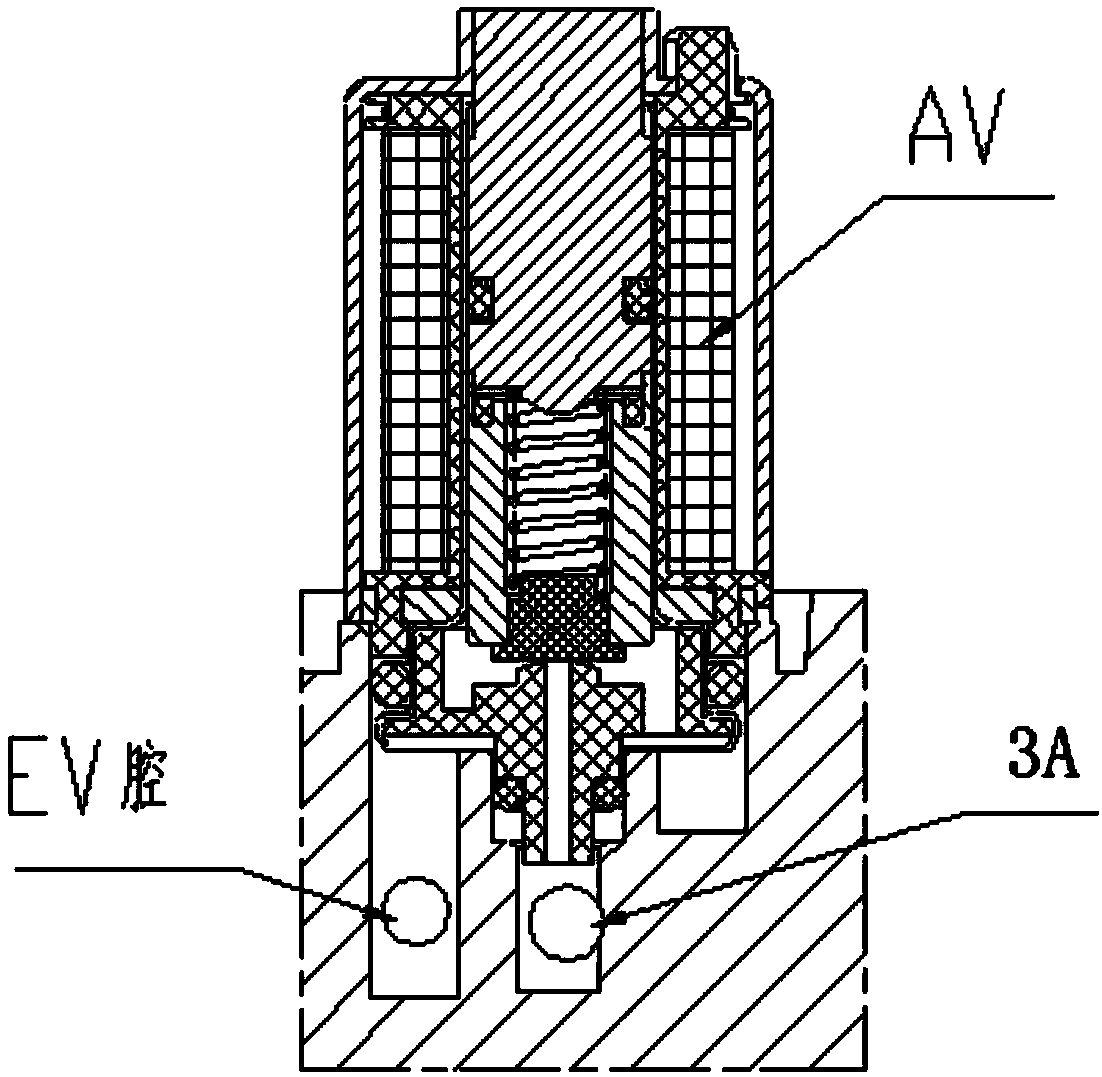

[0022] Such as figure 1 As shown, the trailer control valve of the present invention includes a nut 1, a bolt 2, a base plate 3, a cover 4, a large piston 5, a steel wire retaining ring 6, a piston sleeve 7, a push rod piston 8, a compression spring 9, and a retaining ring 10 for a hole. , guide piston 11, gasket 12, main piston 13, controller housing 14, circuit board 15, air guiding rod 16, muffler housing 19, booster valve 22, pressure reducing valve 23, backup pressure valve 24, valve body 25, The valve body is provided with an inner cavity, and the inner cavity of the valve is provided with a service brake cavity, a large piston return cavity, a booster cavity, an air outlet cavity, and a parking cavity in sequence from top to bottom. Air intake port 1A, air supply port 21A, air outlet port 22A, exhaust port 3A, driving control port 42A and parking control port 43A.

[0023] Nut 1 and bolt 2 securely connect the bottom plate 3 with the valve body 25; the cover 4 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com