A portable mobile robot

A mobile robot and portable technology, applied in the field of mobile robots, can solve the problems of poor obstacle surmounting ability and insufficient load capacity, and achieve the effect of strong obstacle surmounting ability, convenient transformation and enhancement of obstacle surmounting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

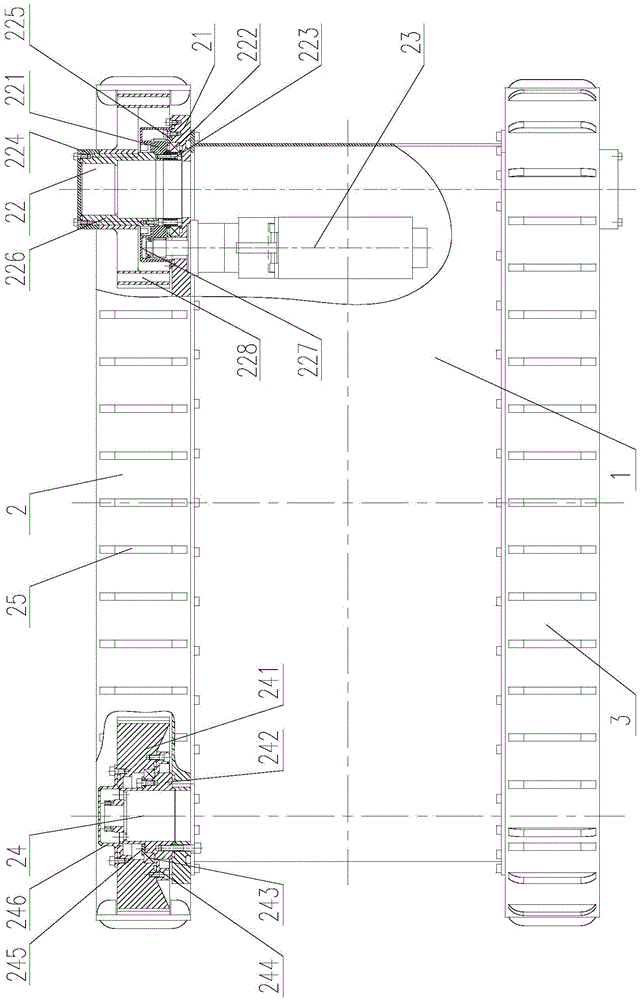

[0026] Embodiment 1 (Mode 1)

[0027] Such as figure 1 As shown, the portable mobile robot of this embodiment includes a box body 1, a left walking mechanism 2, and a right walking mechanism 3, wherein the left walking mechanism 2 includes a left side plate 21, a front wheel assembly 22, a left front wheel drive Assembly 23 , rear wheel assembly 24 and drive track 25 . The left side side plate 21 is an important part of the left side running gear 2, and is used to install the front wheel assembly 22, the left front wheel drive assembly 23 and the rear wheel assembly 24, and the left front wheel drive assembly 23 and the front wheel assembly 22 are respectively located at The inside and outside of the left side plate 21 front; Mounted with end gears. Front wheel assembly 22 comprises bull gear 221, cross roller bearing 222 for drive wheel, drive shaft 223, drive wheel bearing end cover 225, spline shaft 226 for drive wheel, seal cover 227 and drive wheel 228, and drive shaft...

Embodiment 2

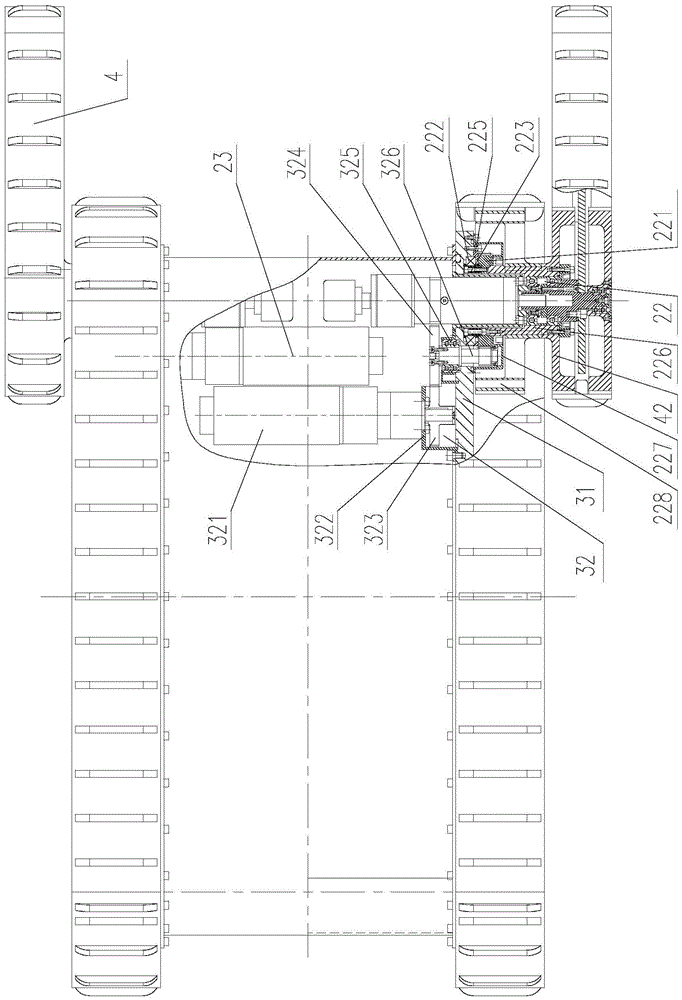

[0034] Embodiment two (mode two)

[0035] The difference between this embodiment and Embodiment 1 is that the outer sides of the drive wheel spline shafts 226 in the front wheel assemblies 22 on the left and right sides are not bolted to the drive wheel end cover 224, but are respectively connected to small arm assemblies with the same structure. 4. Such as figure 2 As shown, the small arm assembly 4 includes a small arm transmission shaft 41, a small arm driving wheel 42, a small arm 43, a small arm support wheel 44, a small arm track 45 and a small arm drive assembly 46, and two small arm drive assemblies on the left and right sides The fixed ends of 46 are respectively bolted to the front of the left side plate 21 and the right side plate 31, one end of the small arm drive assembly 46 is accommodated in the box body 1, and the other end (output end) is used by the drive shaft 223 and the drive wheel. The spline shaft 226 passes through the middle and is keyed to the smal...

Embodiment 3

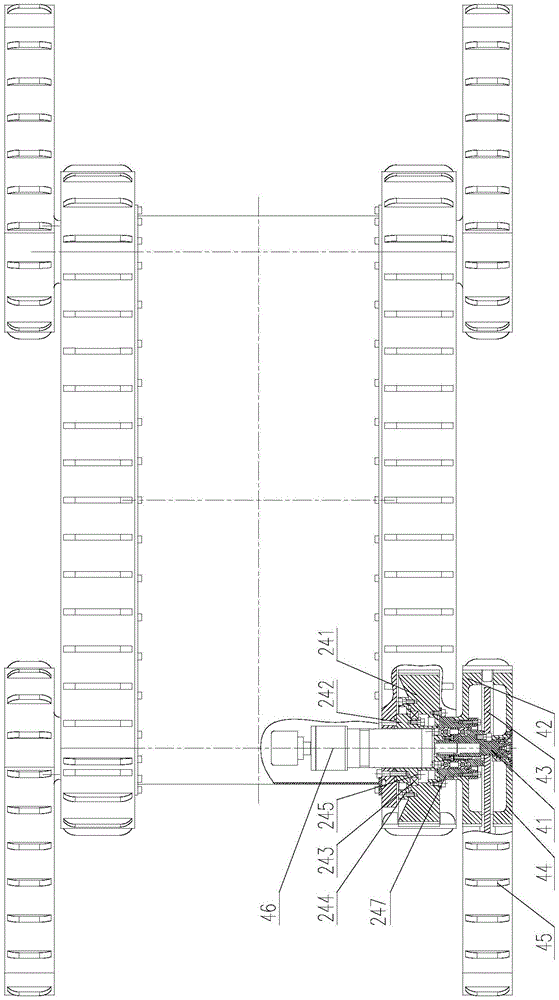

[0039] Embodiment three (mode three)

[0040] The difference between this embodiment and the second embodiment is that the outer sides of the rear wheels 241 in the left and right rear wheel assemblies 24 are not bolted to the rear wheel end caps 246 , but connected to the small arm assemblies 4 with the same structure. Such as image 3 As shown, the fixed ends of the two forearm drive assemblies 46 located at the front on the left and right sides are respectively bolted to the front of the left side plate 21 and the right side plate 31, and the two forearm drive assemblies 46 located at the rear on the left and right sides The fixed ends are bolted to the support shafts 242 in the rear wheel assemblies 24 on the left and right sides. One end of the two forearm drive assemblies 46 at the front is housed in the box body 1, and the other end (output end) passes through the middle of the drive shaft 223 and the spline shaft 226 for the drive wheel, and is keyed to the forearm tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com