Car transshipment device for accumulation conveying

A transfer device and accumulation-type technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as insufficient load capacity, easy wear and short life of extrusion wheels and extrusion rings, and achieve operational The effect of improved stability, reliable transmission connection and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

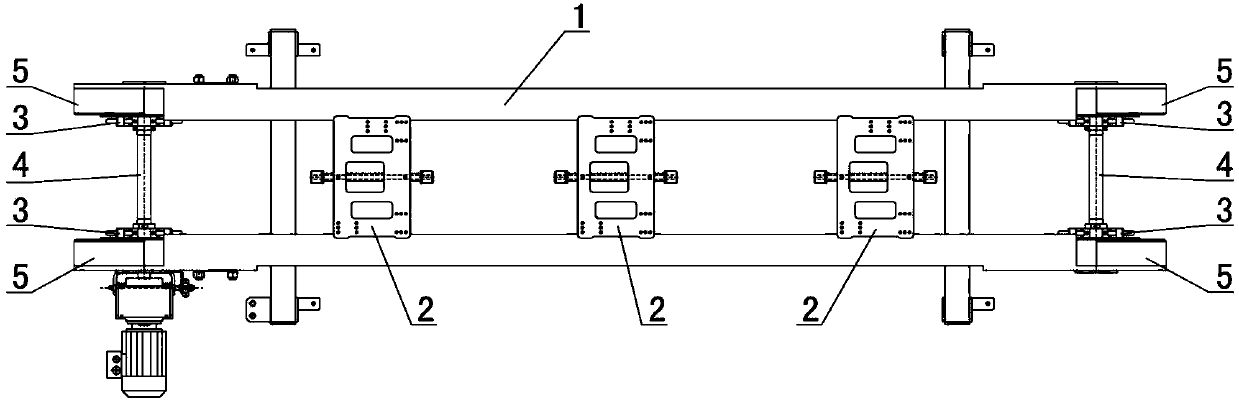

[0025] Such as figure 1 As shown, the whole accumulation conveying device comprising the trolley transfer device of the present invention comprises an accumulation conveying body 1, a transport trolley 2, an annular track 5, a retractable pin device 3 and a rotating shaft 4, and the rotating shaft 4 is driven by a motor (not shown in the figure). mark) drive, figure 1 The chain conveying track and chain driving device in the accumulative and free conveying body 1 are not shown in the figure, which are conventional structures.

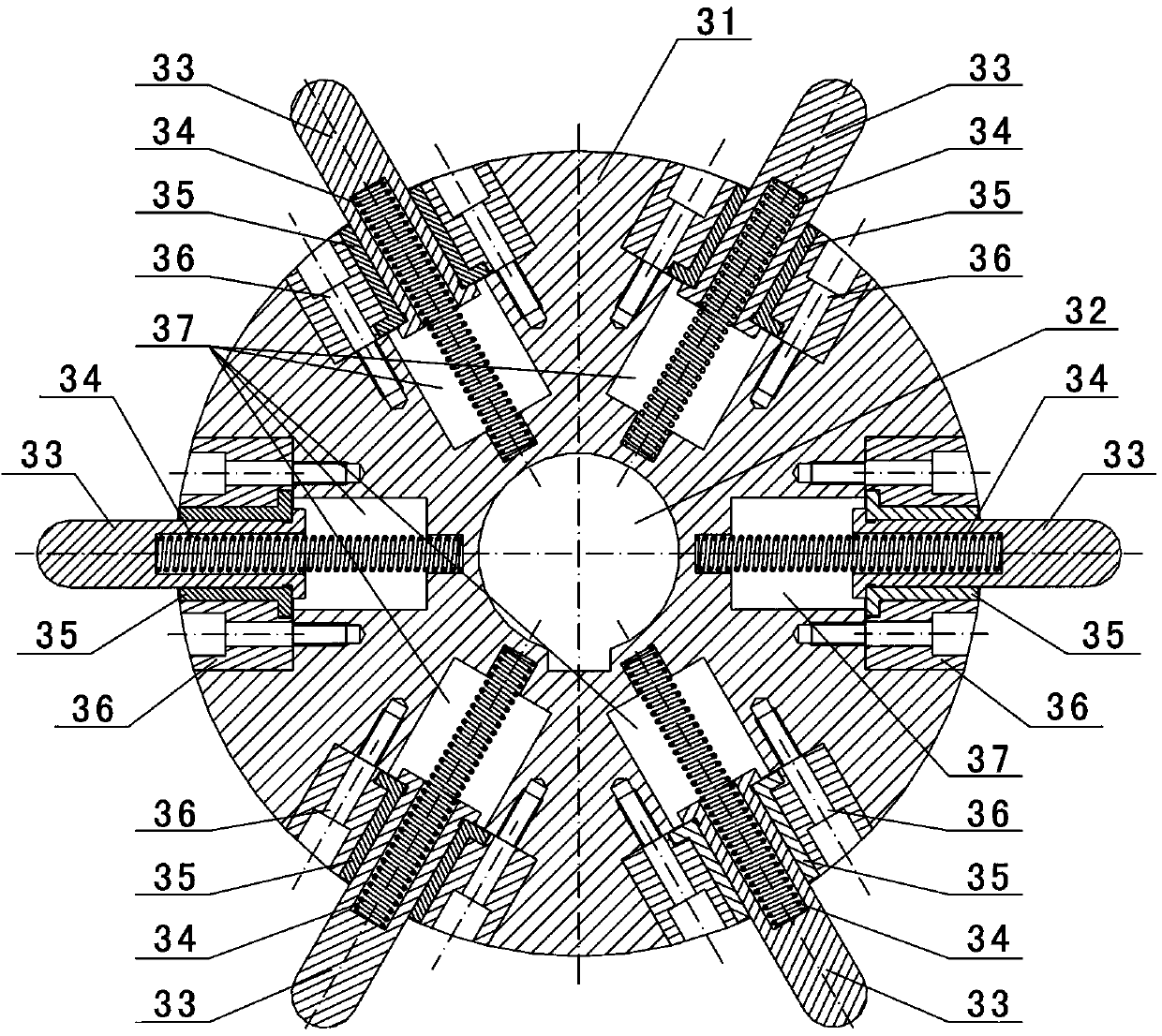

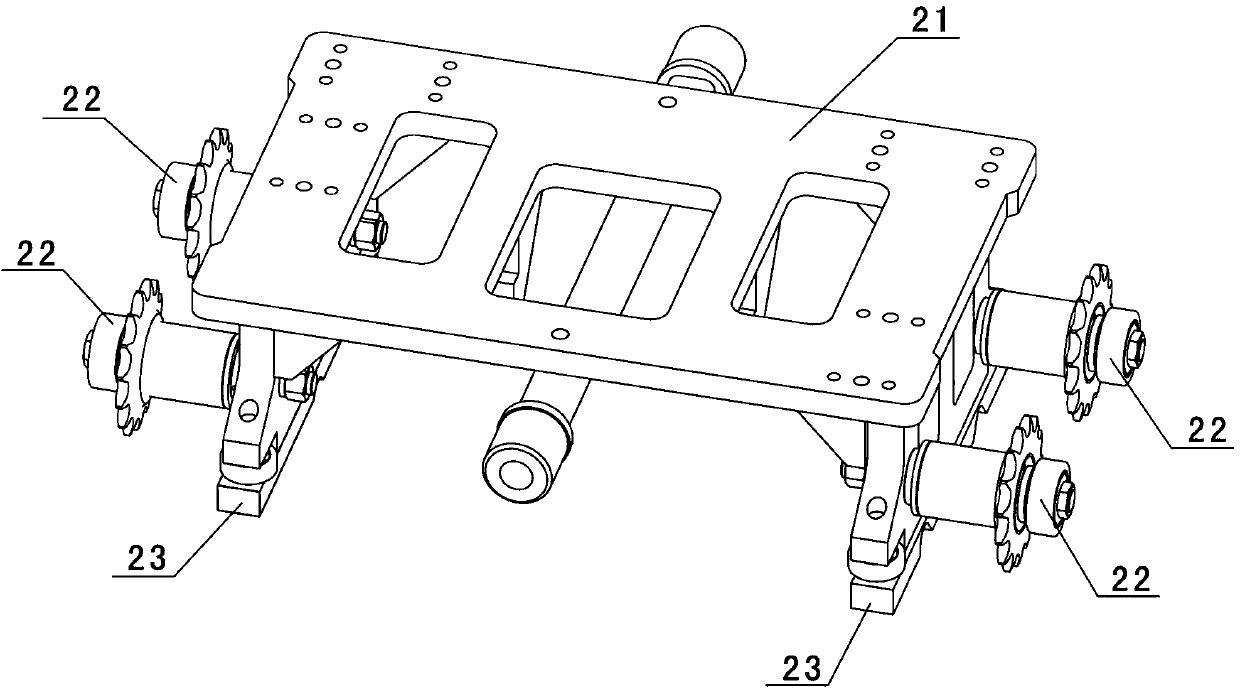

[0026] Such as Figure 1-Figure 6 As shown, the trolley transfer device for accumulating type transportation according to the present invention includes a steering drive device installed on the circular track 5 and used to drive the transport trolley 2, the steering drive device is a telescopic pin device 3, and the telescopic pin device 3 Includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com