Tray pressing and turning device

A flipping device and tray technology, which is applied in the direction of transportation and packaging, conveyor objects, optical testing flaws/defects, etc. It can solve the problems of relatively high positioning requirements for packaged products, unstable clamping devices, and unguaranteed product quality. , to achieve the effects of improving clamping accuracy and flipping accuracy, saving labor, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

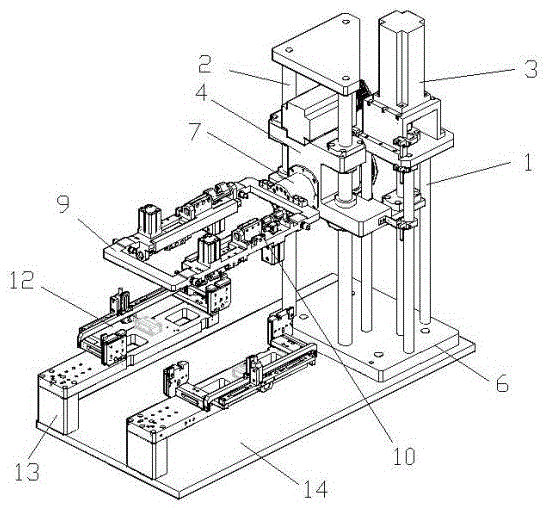

[0042] see Figure 1~Figure 10 , The invention relates to a pallet pressing and turning device, which includes a lifting component, a turning component, a clamping component and a pallet pressing height detection component.

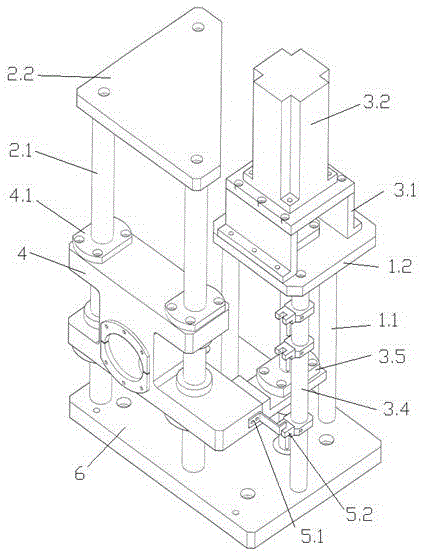

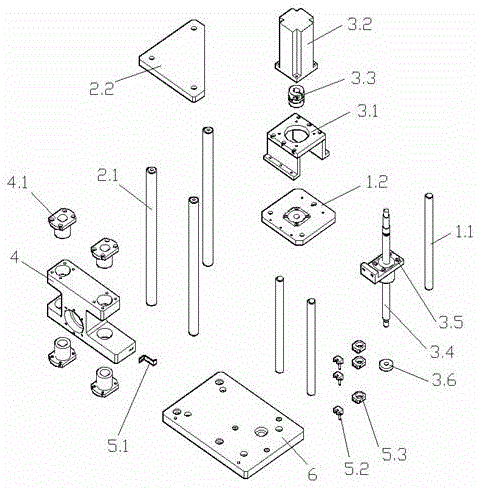

[0043] The lift assembly includes a first support 1 , a second support 2 , a lift control mechanism 3 disposed on the first support 1 , a lift seat 4 disposed on the second support 2 , a lift detection member 5 and a first bottom plate 6 .

[0044] The second bracket 2 and the first bracket 1 are arranged left and right on the first bottom plate 6. The first bracket 1 includes three vertically arranged first support rods 1.1 and a first platform 1.2 connected to the top of the three first support rods 1.1, The second support 2 includes three second support rods 2.1 arranged vertically and a second platform 2.2 connected to the top of the three second support rods 2.1.

[0045] The lifting control mechanism 3 includes a first motor base 3.1, a first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com