Supporting system for concrete precast component

A technology of prefabricated components and support systems, which is applied to the preparation of building components on site, pillars, and building structures. The effect of support device reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

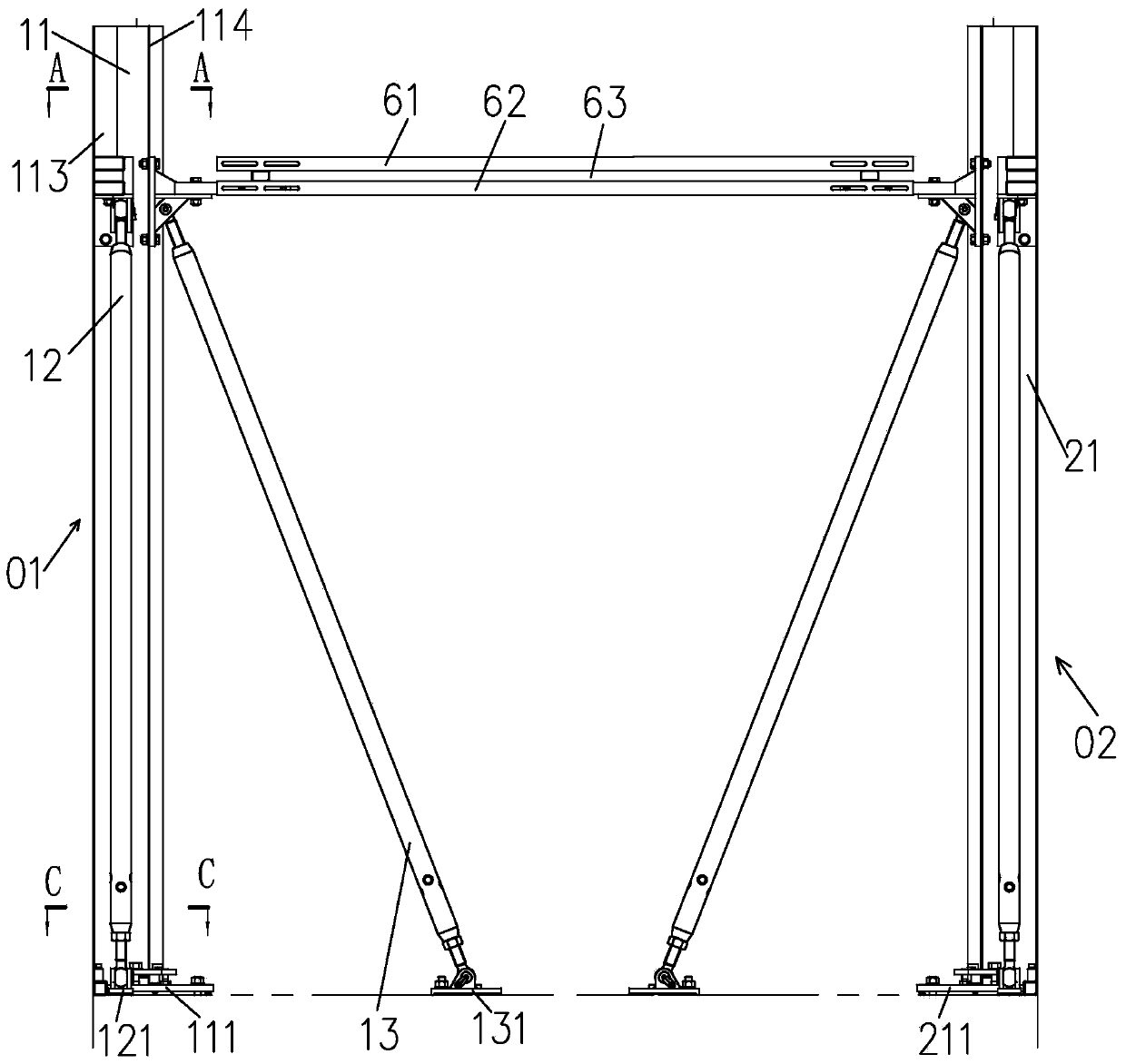

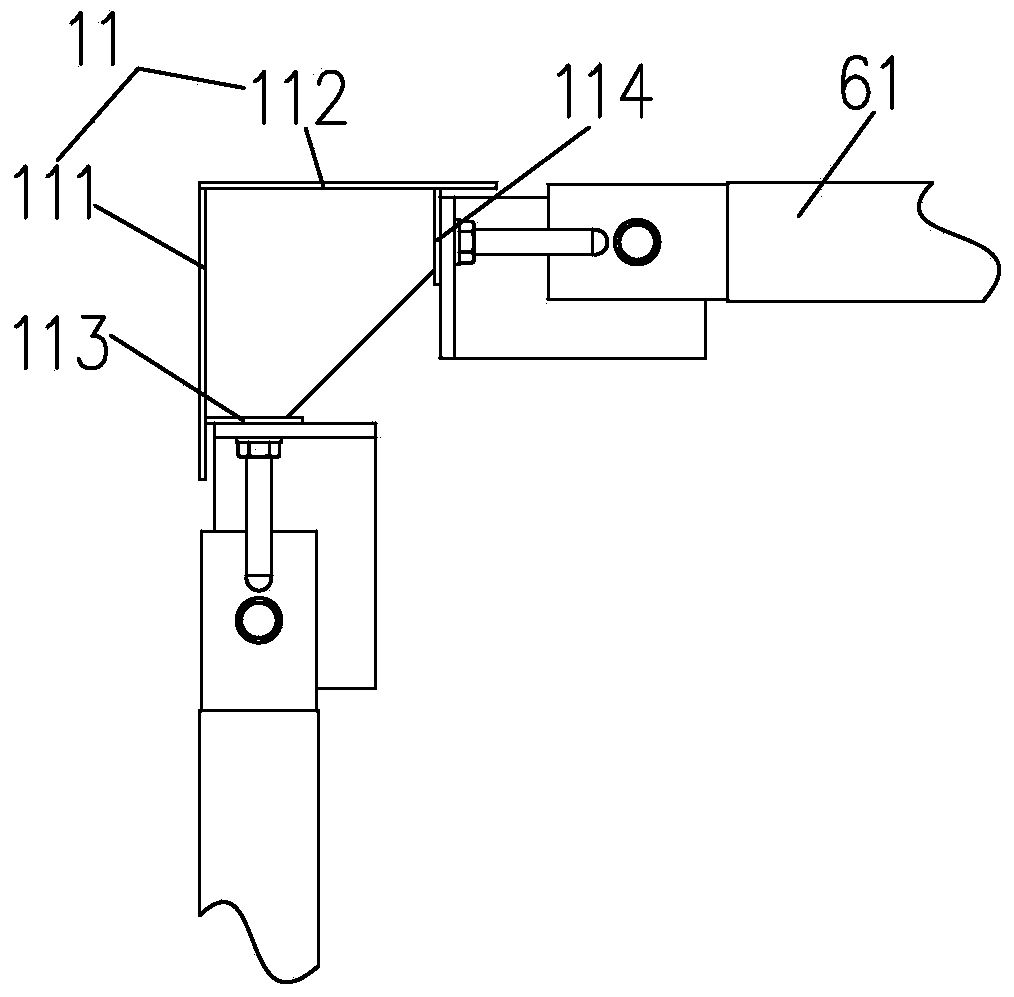

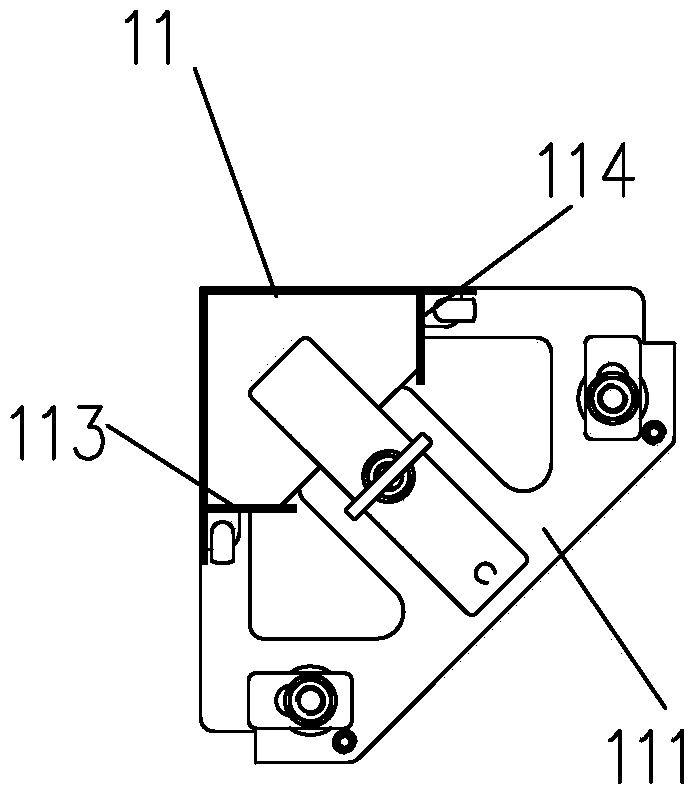

[0019] Such as figure 1 The first embodiment of the supporting system of the concrete prefabricated component of the present invention includes a first group of supporting devices 01, a second group of supporting devices 02, and first and second connecting rods 61 and 62. The first group of supporting devices 01 includes a first vertical Plate 11 and two oblique support rods 12,13, such as figure 2 As shown, the first vertical plate 11 is an L-shaped plate, and the first and second side walls 111, 112 form an L shape. The lengths of the two ends of the two oblique support rods 12, 13 can be adjusted. On a vertical plate chassis 111, the first vertical pole chassis 111 is connected to the ground through ground reserved bolts, two oblique support rods 12, 13 are located on the inner side of the first vertical plate 11, and the lower end of one oblique support rod 12 is hinged to the ground The upper and upper ends are hinged on the first vertical plate 11 near the top, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com