Smoke damper door drive mechanism

A driving mechanism and baffle door technology, which is applied in the field of smoke baffle door and smoke baffle door driving mechanism, can solve the problems of troublesome disassembly, cumbersome transfer and maintenance, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

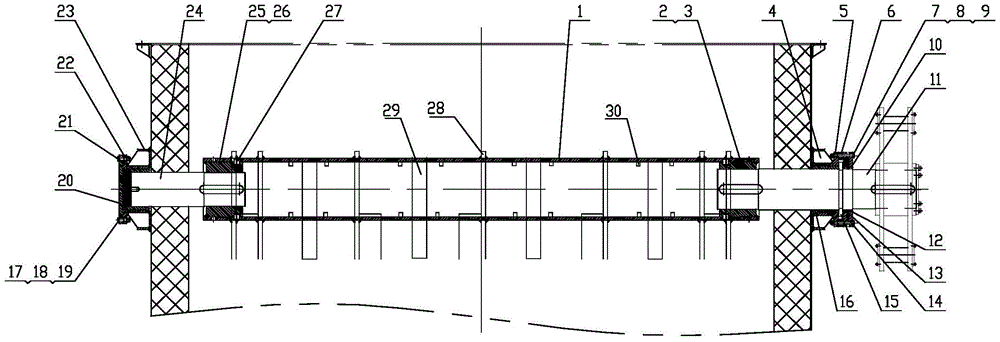

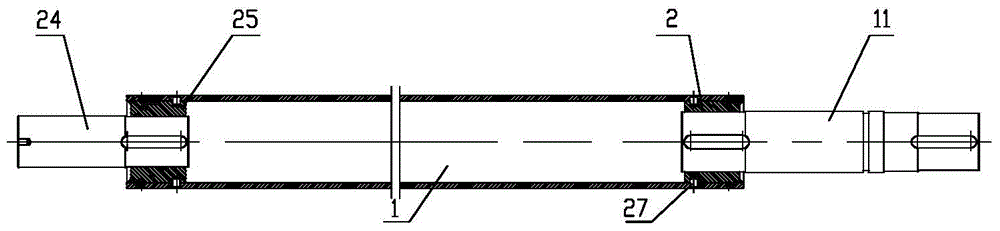

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] figure 1 , 2 Among them, including torque tube 1, front bushing 2, first flat key 3, front support seat 4, front bearing seat 5, washer 6, first hexagonal bolt 7, first spring washer 8, first nut 9, packing Cover 10, front axle 11, clip ring 12, seal ring 13, Huff ring 14, retainer ring 15, front bearing 16, second hex bolt 17, second spring washer 18, second nut 19, rear cover 20, Rear bearing 21, rear bearing cap 22, rear support base 23, rear axle 24, rear axle sleeve 25, the second flat key 26, bearing pin 27, reversing baffle 28, rotating plate 29, limit baffle 30 etc.

[0015] Such as figure 1 , 2 As shown, the present invention is a smoke baffle door driving mechanism, which includes a front support seat 4 arranged at the front end of the three-way housing and a rear support seat 23 arranged at the rear end of the three-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com