Turnout switch machine display bar gap width monitoring system and its eddy current sensor

An eddy current sensor and a technology of indicating rods, which are applied in the field of electronic communication and can solve the problems of no quantitative detection results, too large probes, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

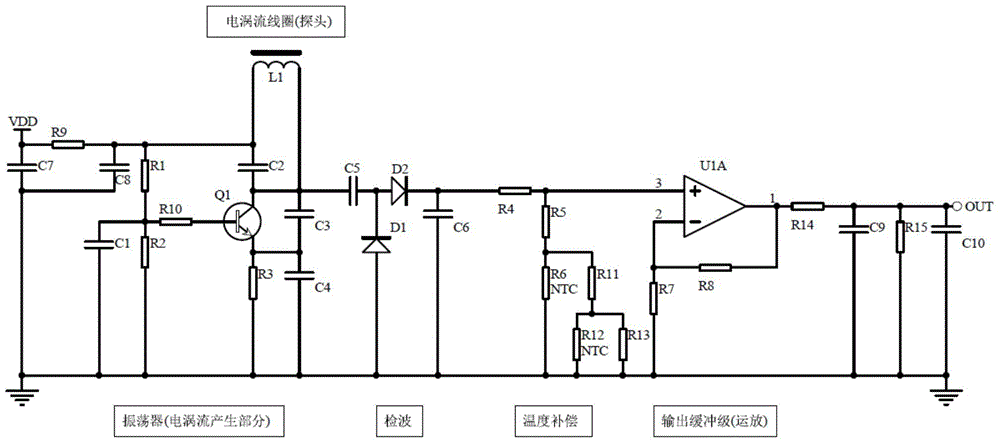

[0097] see figure 1 , the present invention discloses an eddy current sensor used for monitoring the gap width of the indication bar of a turnout switch machine, the eddy current sensor comprises: an eddy current probe and an eddy current circuit, the eddy current probe is connected with the eddy current circuit; The eddy current circuit includes an oscillator module, a wave detection module, a temperature compensation module, and an output buffer stage module.

[0098] The eddy current sensor uses a high-frequency oscillating current to pass through the eddy current probe to generate an alternating magnetic field at the head of the eddy current probe. When a metal conductor moves within the effective range of this alternating magnetic field, the magnetic field will change with the movement of the metal. Change, which is converted into a voltage or current change and passed to the collector module of the monitoring system.

[0099] The oscillator module is responsible for gen...

Embodiment 2

[0106] see figure 1 , the present invention discloses an eddy current sensor used for monitoring the gap width of the indication bar of a turnout switch machine, the eddy current sensor comprises: an eddy current probe and an eddy current circuit, the eddy current probe is connected with the eddy current circuit; The eddy current circuit includes an oscillator module, a wave detection module, a temperature compensation module, and an output buffer stage module.

[0107] The eddy current sensor uses a high-frequency oscillating current to pass through the eddy current probe to generate an alternating magnetic field at the head of the eddy current probe. When a metal conductor moves within the effective range of this alternating magnetic field, the magnetic field will change with the movement of the metal. Change, which is converted into a voltage or current change and passed to the collector module of the monitoring system.

[0108] The oscillator module is responsible for gen...

Embodiment 3

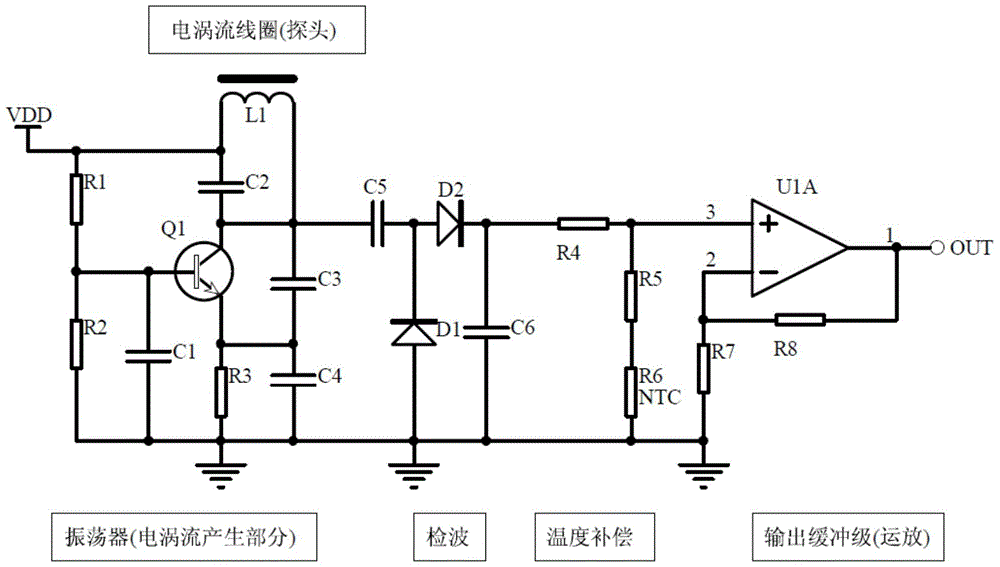

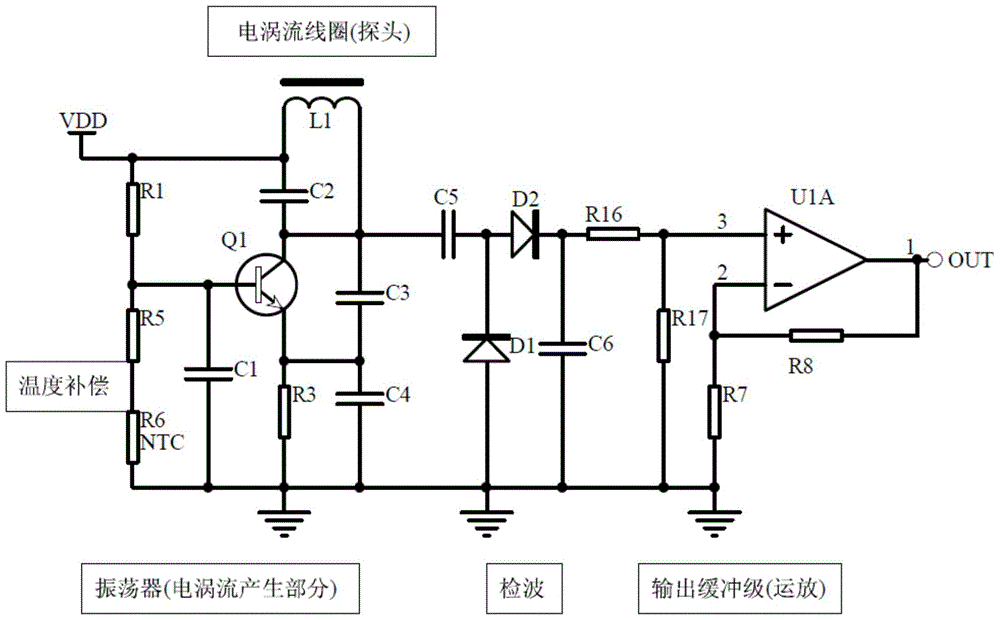

[0111] see figure 2 , in this embodiment, the oscillator module, the detection module, the temperature compensation module, and the output buffer stage module are connected in sequence.

[0112] The oscillator module adopts the principle of a capacitor three-point oscillator, mainly including a first resistor R1, a second resistor R2, a third resistor R3, a first capacitor C1, a second capacitor C2, a third capacitor C3, and a fourth capacitor C4. Transistor Q1, and eddy current coil L1; wherein, the first end of the first resistor R1 is connected to the power supply VDD, the second end of the second resistor R2 is grounded, and the second end of the first resistor R1 and the first end of the second resistor R2 are respectively Connect the base of the amplifying transistor Q1 to provide a bias voltage for the amplifying transistor Q1; the second capacitor C2, the third capacitor C3, the fourth capacitor C4, and the eddy current coil L1 form a three-point oscillation circuit; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com