Mirror displacement measurement method based on feature pattern reflecting

A displacement measurement and feature pattern technology, applied in the field of mirror displacement measurement and testing, to achieve the effects of high sensitivity, simple structure and large measurement dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

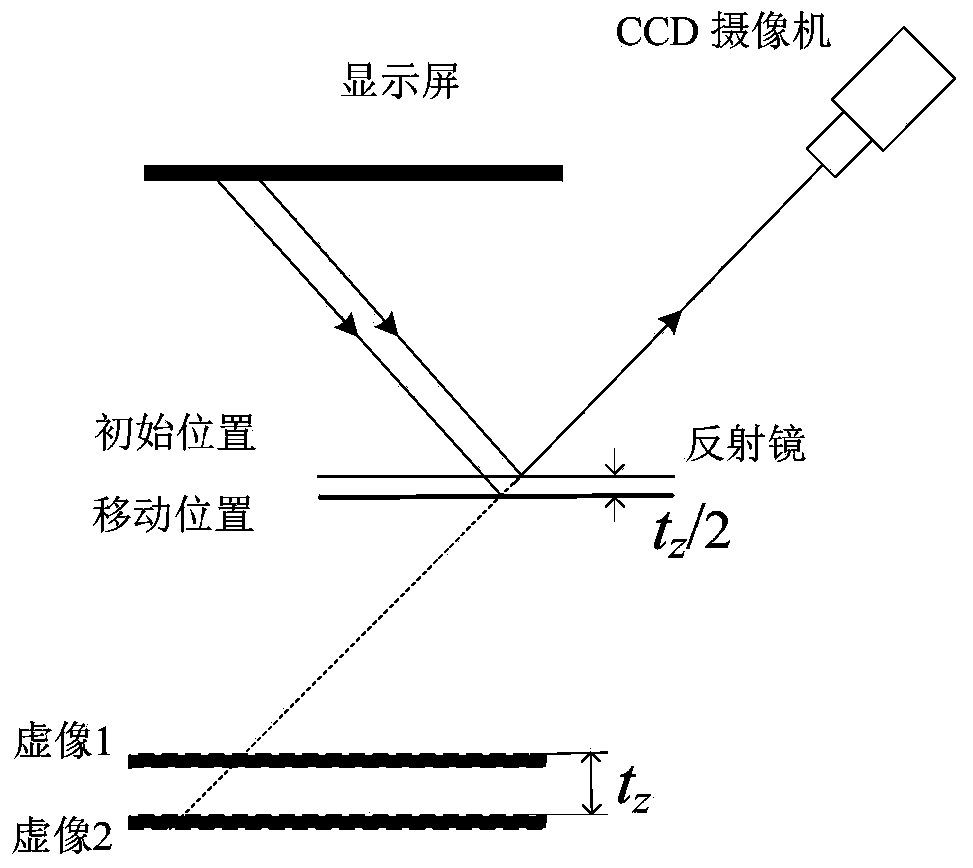

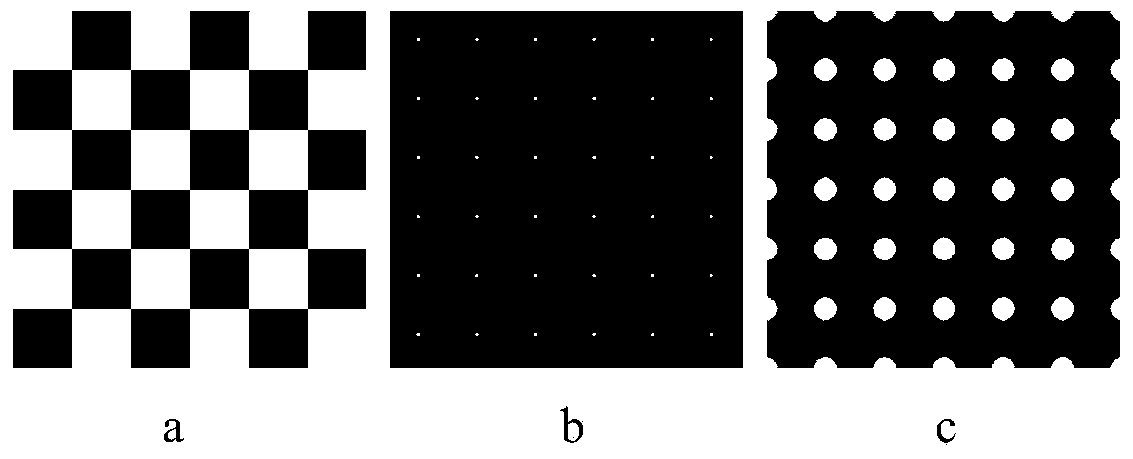

[0018] Such as figure 1 As shown, the system includes a CCD camera, a display screen and a computer. The characteristic patterns generated by the computer are displayed on the display screen, and are captured and recorded by the CCD camera after being reflected by the measured object or the mirror fixed on the object. That is, the CCD shoots and records the virtual image formed by the reflector on the display screen. When the mirror moves, the virtual image also moves relative to the camera. By calibrating the extrinsic parameters of the camera, the moving distance of the virtual image relative to the camera before and after the movement of the mirror can be calculated. According to the law of light reflection, half of this distance is the moving distance of the mirror. The following takes the checkerboard feature pattern displayed on the display as an example for illustration.

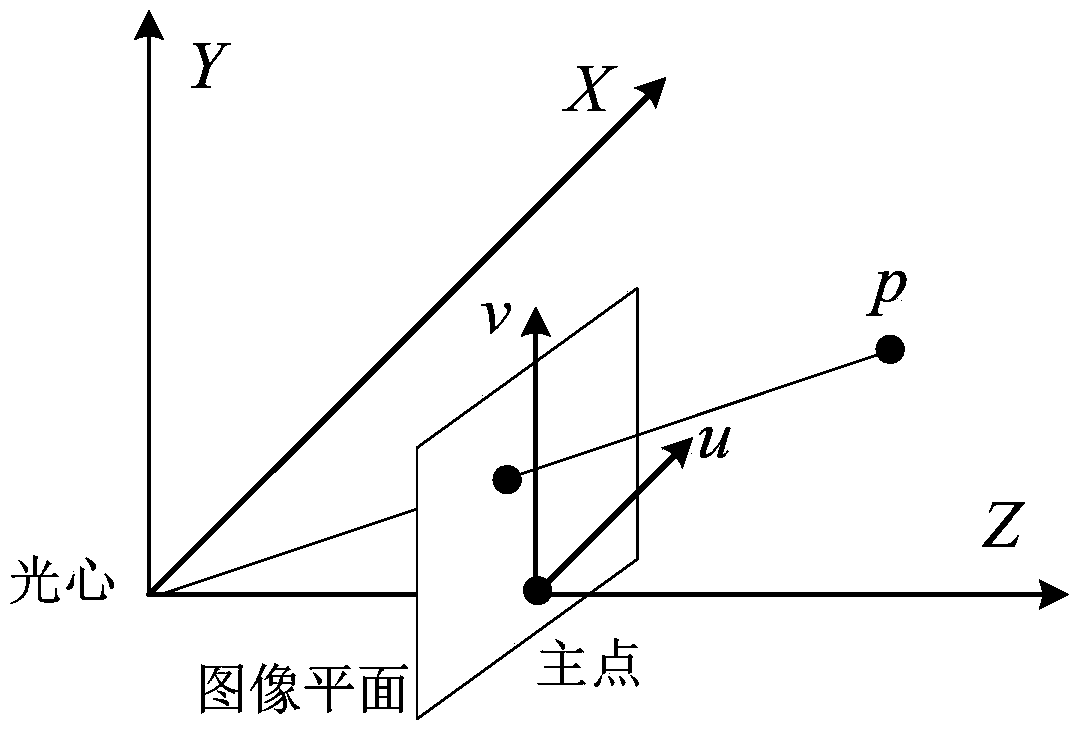

[0019] Firstly, the internal parameters of the camera are obtained through standardization. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com