An automobile weather strip durability test equipment

An automotive sealing strip and durability test technology, applied in the field of measurement, can solve the problems of inability to verify in advance, long test cycle of endurance test equipment, and measured wear of the sealing strip, etc., and achieves fast test cycle, small error and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

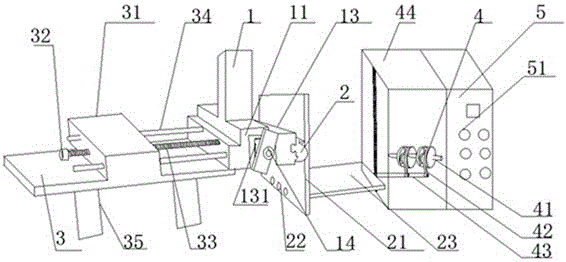

[0029] Please refer to figure 1 , figure 1 It is a structural schematic diagram of an automobile weather strip durability test equipment of the present invention. The test equipment is provided with a tooling body 1 , a height valve 32 , an automobile sheet metal part 21 and a variable frequency motor 4 . The tool body 1 is in the shape of a "T" and is located on the bottom plate 3. The tool body 1 is provided with a first clamping surface 11 and a second clamping surface (the surface opposite to the first clamping surface 11). ), the third clamping surface (i.e. the top surface of the tooling body 1) and the fourth clamping surface (ie the bottom surface of the tooling body 1), the tooling body 1 is also provided with a round hole (not marked in the figure); The base plate 3 is placed on the support leg 35, and the base plate 3 is provided with a bump 31; the bump 31 and the base plate 3 are integrally formed; the bump 31 is provided with a round hole (not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com