High-hydrostatic-pressure low-frequency calibrating cavity and testing method thereof

A high hydrostatic pressure, low frequency technology, applied in the direction of measuring device, radio wave measurement system, material analysis using sound wave/ultrasonic wave/infrasonic wave, etc., it can solve the problems that cannot meet the hydrostatic pressure of 50MPa or even higher, the measurement procedures and device maintenance are cumbersome, and cannot be solved Low-frequency sensitivity calibration and other issues, to achieve the effect of fast test speed, high test efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

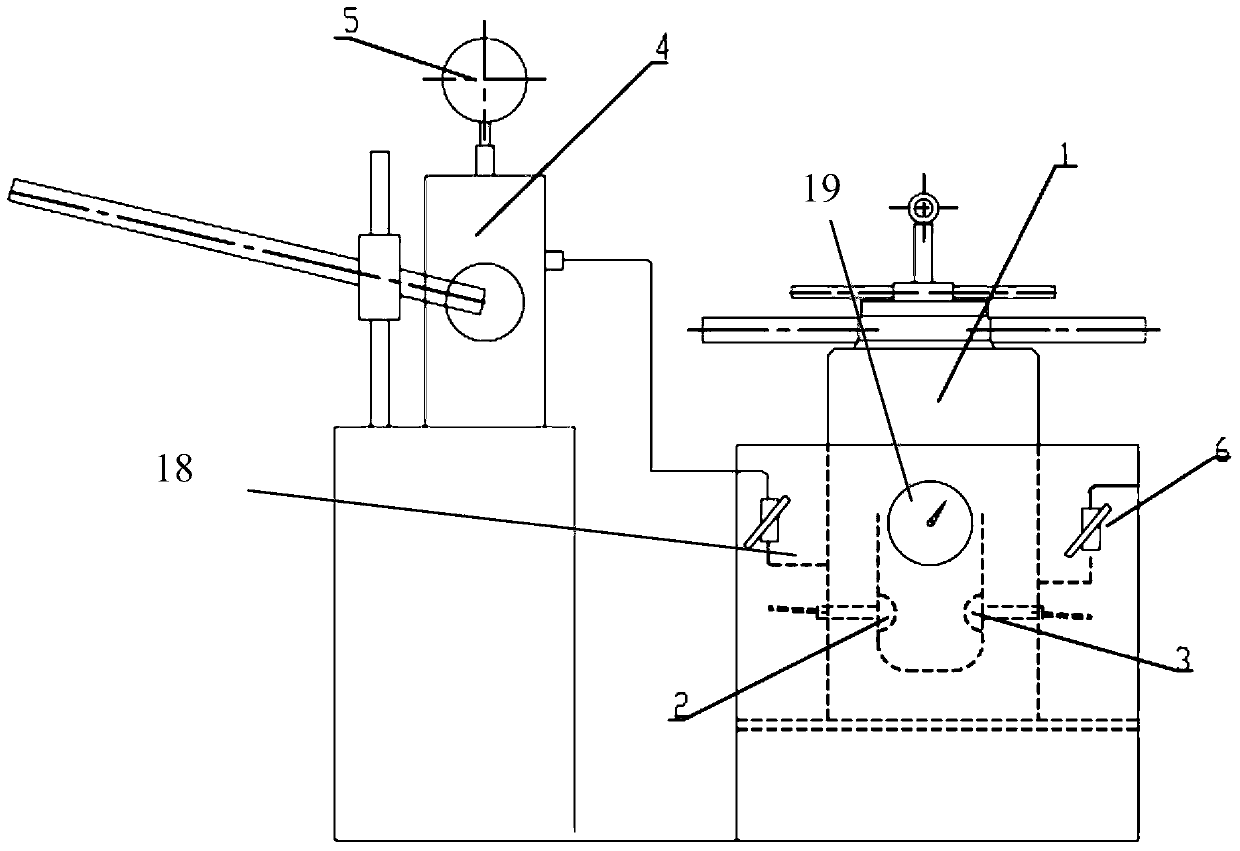

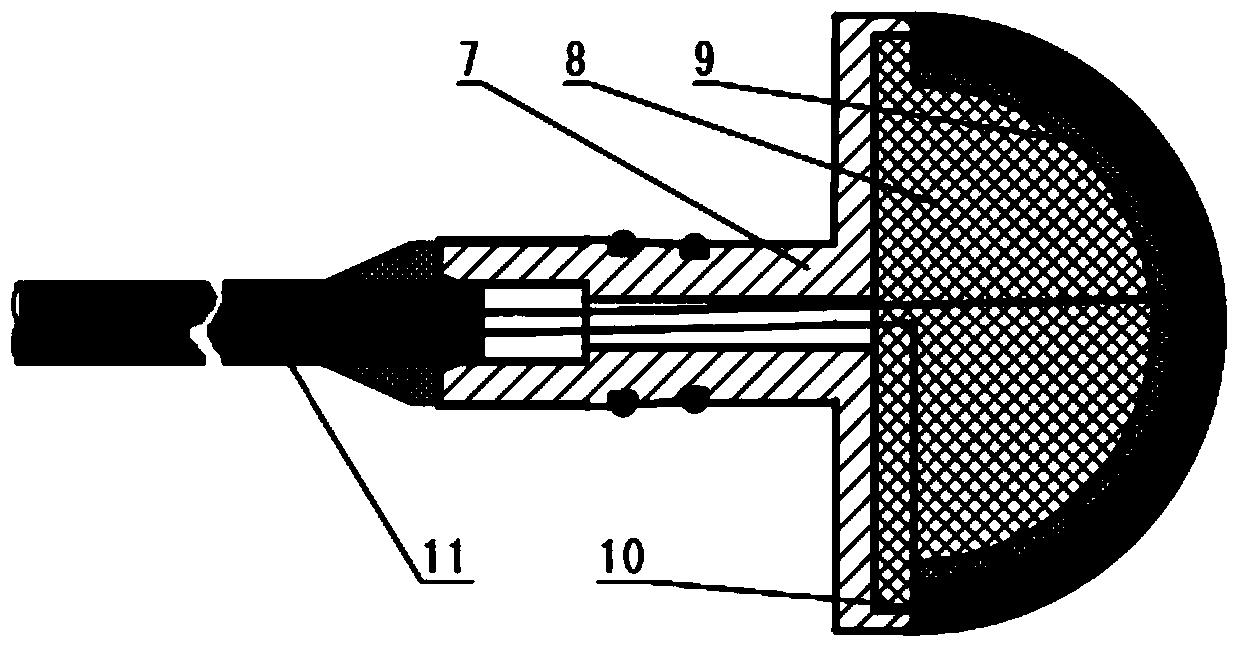

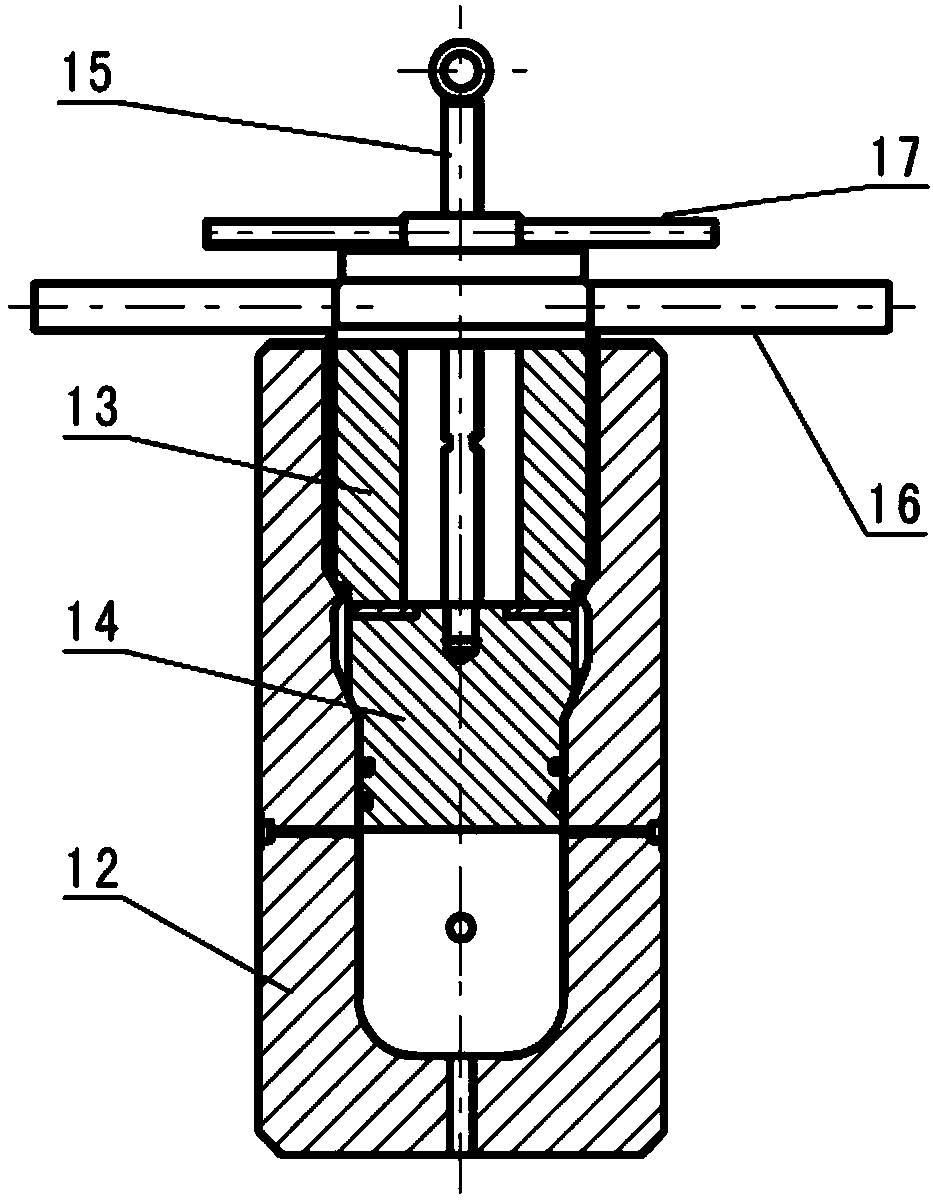

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] In order to solve the calibration of the low-frequency sensitivity of the hydrophone under the condition of high hydrostatic pressure, the present invention proposes a piezoelectric ceramic hemispherical transmitting transducer to transmit acoustic signals to form a uniform sound field in a rigid closed metal cavity. The piezoelectric transducer emits sound signals, and the manual pressure pump provides a high hydrostatic pressure environment in the cavity. The hydrophone under test and the reciprocal transducer test the low-frequency receiving sensitivity by comparison method, and the manual pressure pump provides the metal cavity with the required High hydrostatic pressure, so as to realize the calibration measurement of low frequency receiving sensitivity under high hydrostatic pressure up to 70MPa.

[0022]As shown in the figure, this high hydrosta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com