A steam generator controller

A generator controller, generator technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as inconvenient operation, disadvantageous intelligent upgrade, disadvantageous rapid maintenance, etc., and achieves convenient operation, Improve heat energy conversion efficiency and respond quickly to load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

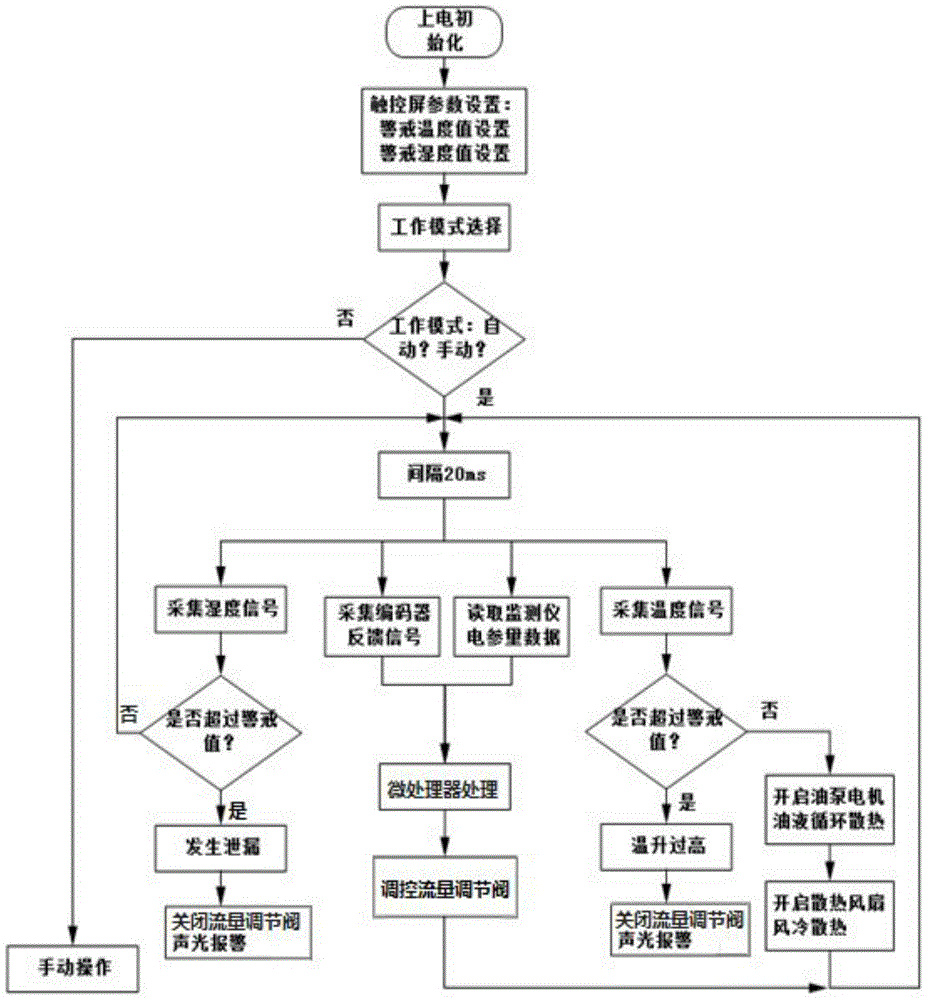

[0031] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

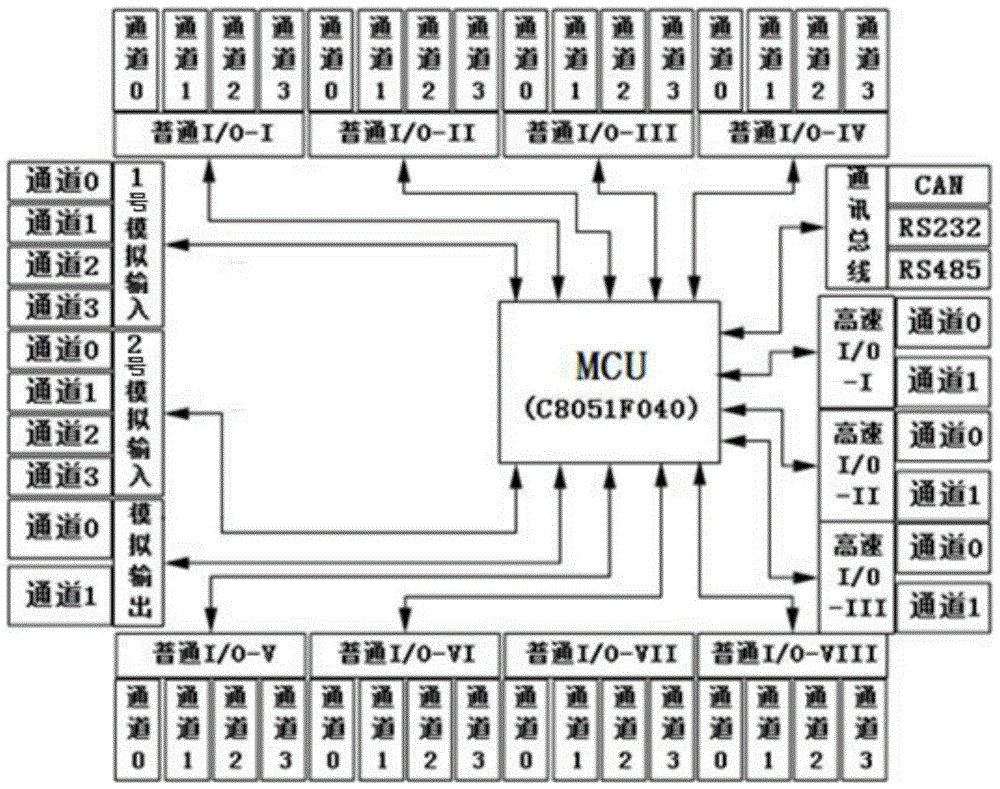

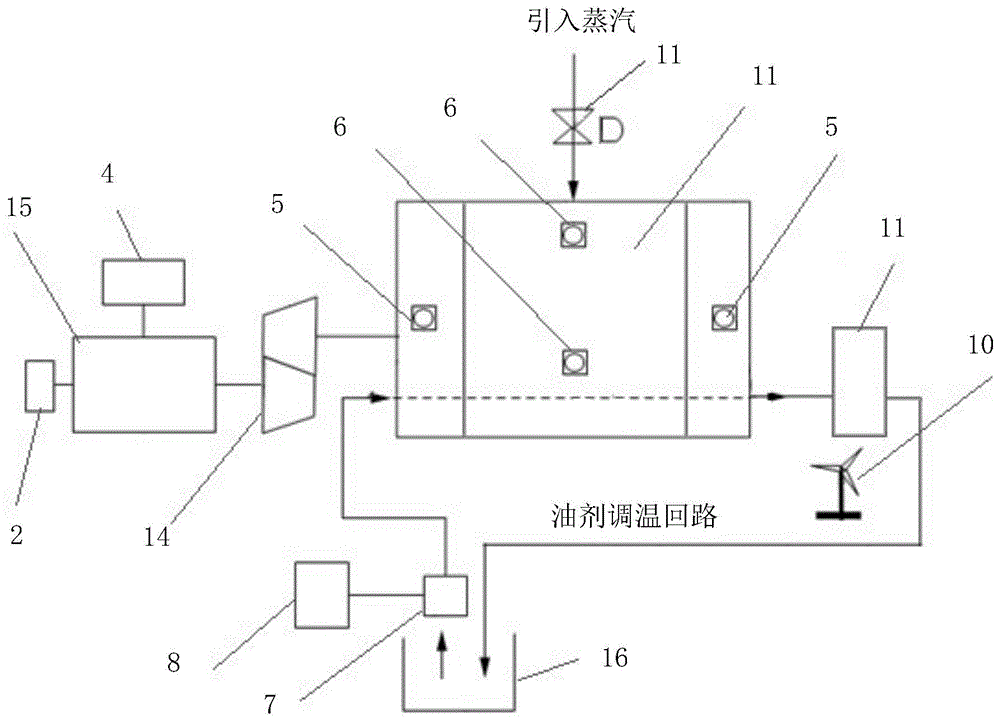

[0032] The steam generator controller (being called for short controller, referring to Figure 1-3 ), which is used to regulate the steam power machine 13, speed-increasing mechanism 14 and generator 15, and is characterized in that: the controller includes a microprocessor 1 and a power supply module 12, and also includes an encoder 2, a flow regulating valve 3, a monitor 4. Temperature sensor 5, humidity sensor 6, oil pump 7, motor 8, control panel 9, fan 10, radiating pipe 11 and oil tank 16; the speed increasing mechanism 14 is installed between the steam power machine 13 and the generator 15;

[0033] The microprocessor 1 is the core component of the entire controller, and is connected with the power module 12, the encoder 2, the flow regulating valve 3, the monitor 4, the temperature sensor 5, the humidity sensor 6, the motor 8, the control panel 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com