Novel structure cable and manufacturing method

A new type of structure and cable technology, which is applied in the field of electric power and cables, can solve the problem of unsatisfactory heat dissipation effect, and achieve the effect of less material consumption, reasonable process and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

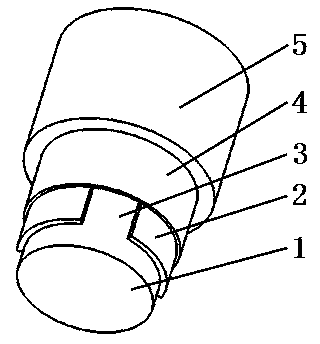

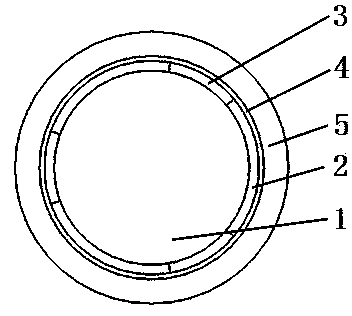

[0037] please see figure 1 with figure 2 , a new type of structural cable, which includes a conductor 1, an isolation layer 4, and a sheath layer 5; it is characterized in that there are three filling strips 2 outside the conductor, and there are gaps 3 between adjacent filling strips, and the isolation layer covers Covered on the filling strip, the sheath layer is extruded and coated on the outside of the isolation layer; the filling strip is attached to the surface of the conductor.

Embodiment 2

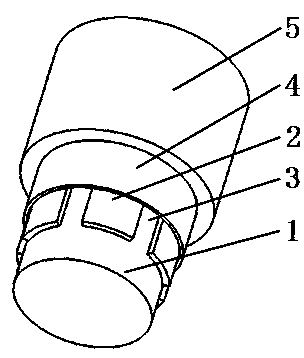

[0039] please see image 3 with Figure 4 , a new type of structural cable, which includes a conductor 1, an isolation layer 4, and a sheath layer 5; it is characterized in that there are six filling strips 2 outside the conductor, and there are gaps 3 between adjacent filling strips, and the isolation layer covers Covered on the filling strip, the sheath layer is extruded and coated on the outside of the isolation layer; the filling strip is attached to the surface of the conductor.

Embodiment 3

[0041] please see Figure 5 with Image 6 , a new type of structural cable, which includes a conductor 1, an isolation layer 4, and a sheath layer 5; it is characterized in that there are three filling strips 2 outside the conductor, and there are gaps 3 between adjacent filling strips, and each interval There is a heat dissipation strip 6 below, and the heat dissipation strip connects the adjacent filling strips. There are heat dissipation holes on the heat dissipation strip. Each heat dissipation hole runs through the heat dissipation strip. The surface of the conductor; the isolation layer is coated on the outside of the filling strip, and the sheath layer is extruded and coated on the outside of the isolation layer; the filling strip is attached to the surface of the conductor; the heat dissipation strip is integrally formed with the filling strip; the heat dissipation strip is also attached on the conductor surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com