Solar cell packaging method

A technology of solar cells and encapsulation methods, which is applied in the field of solar cells, can solve problems such as poor sealing performance and inability to effectively protect solar cells for a long time, and achieve the effects of low cost, long life, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

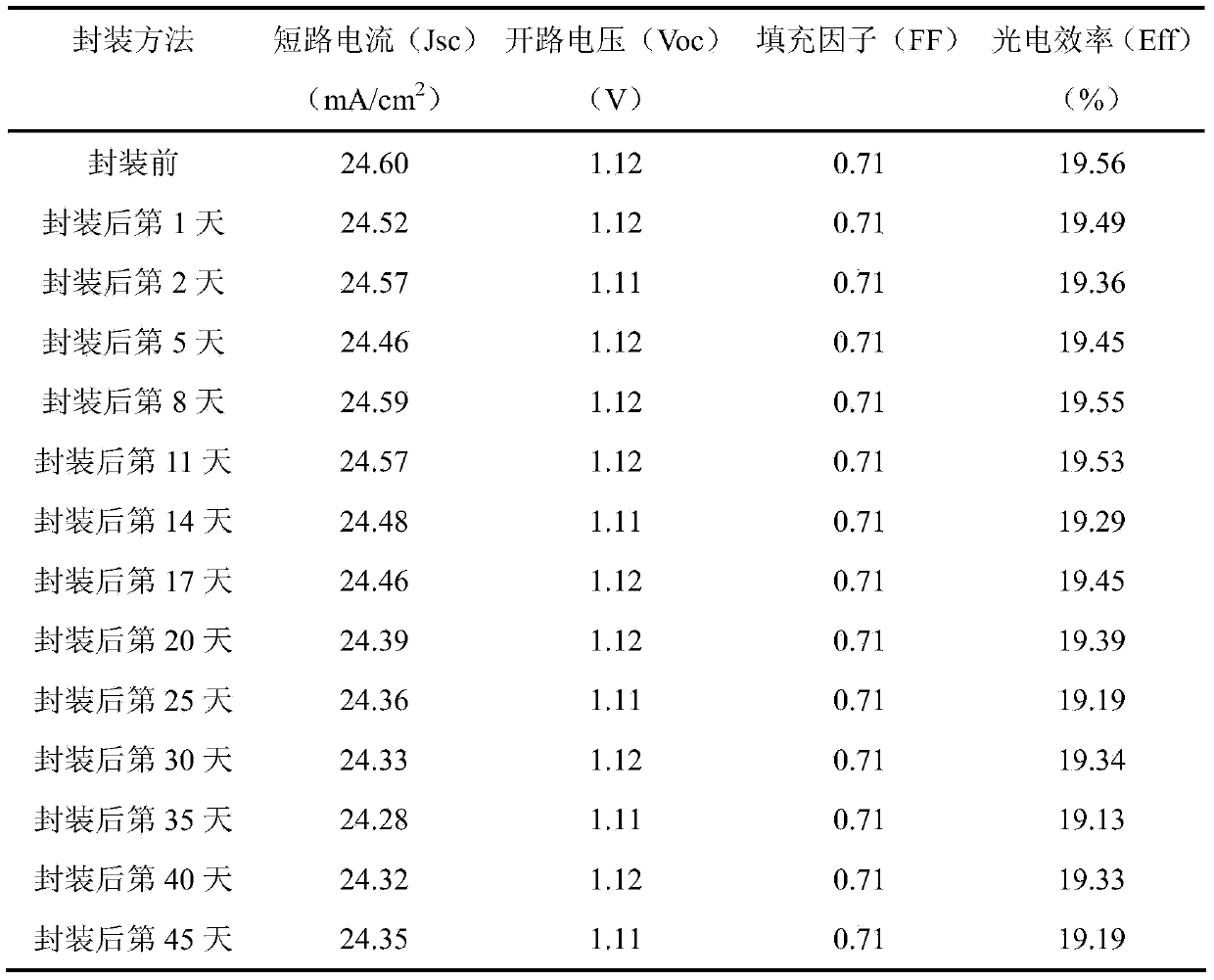

Embodiment 1

[0024] Embodiment 1: Encapsulation of a perovskite solar cell device with an area of 2cm×2cm

[0025] Specific steps are as follows:

[0026] 1) adding graphene with a diameter of 0.3 to 5 μm and a thickness of 10 to 20 nm in bisphenol A epoxy resin, the mass ratio of graphene to bisphenol A epoxy resin is (1 to 2): 100, and the The mechanical stirring of 2h makes graphene evenly disperse in epoxy resin, obtains graphene modified epoxy resin;

[0027] 2) Join curing agent phthalic anhydride in the graphene-modified epoxy resin, the mass ratio of phthalic anhydride and graphene-modified epoxy resin is 1: (1~2), in the vacuum of 50mbar Mechanically blending 2h under condition, obtain curable graphene-modified epoxy resin composition;

[0028] 3) Epoxy technology: Use a curable graphene-modified epoxy resin composition to cover the light-receiving part of the solar cell, so that it is evenly and tightly wrapped around the solar cell, and the curable graphene-modified epoxy re...

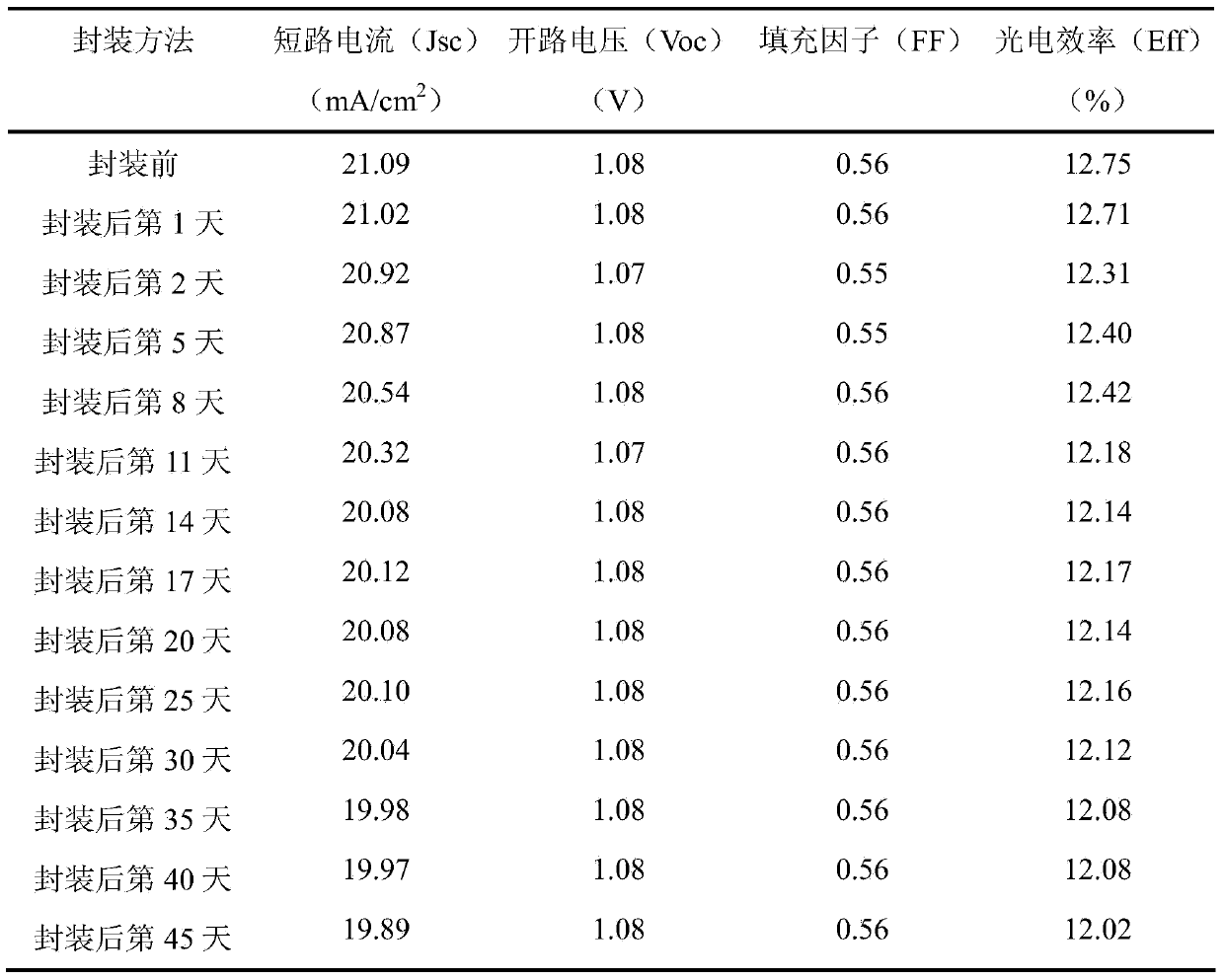

Embodiment 2

[0034] Embodiment 2: Encapsulation of a perovskite solar cell device with an area of 10cm×10cm

[0035] 1) Add graphene with a diameter of 0.3~5 μm and a thickness of 0.3~10 nm into bisphenol A epoxy resin, the mass ratio of graphene to bisphenol A epoxy resin is (0.5~1):100, pass The mechanical stirring of 3h makes graphene evenly disperse in epoxy resin, obtains graphene modified epoxy resin;

[0036] 2) curing agent tetrahydrophthalic anhydride (THPA) is added in the graphene-modified epoxy resin, and the mass ratio of tetrahydrophthalic anhydride (THPA) and graphene-modified epoxy resin is 1: (1~2), mechanically blending 3h under the vacuum condition of 30mbar, obtain curable graphene-modified epoxy resin composition;

[0037] 3) Use photovoltaic ultra-clear glass as the upper layer, polyvinyl fluoride composite film (TPT) as the lower layer, and fill the gap between the upper layer and the lower layer with a curable graphene-modified epoxy resin composition to make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com