Er:YAG tunable single-longitudinal-mode laser with twisted mode cavity

A technology of lasers and torsional modes, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as inability to achieve wavelength tuning, poor beam directivity, and complex structural design, and achieve the effect of eliminating the effect of laser space hole burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

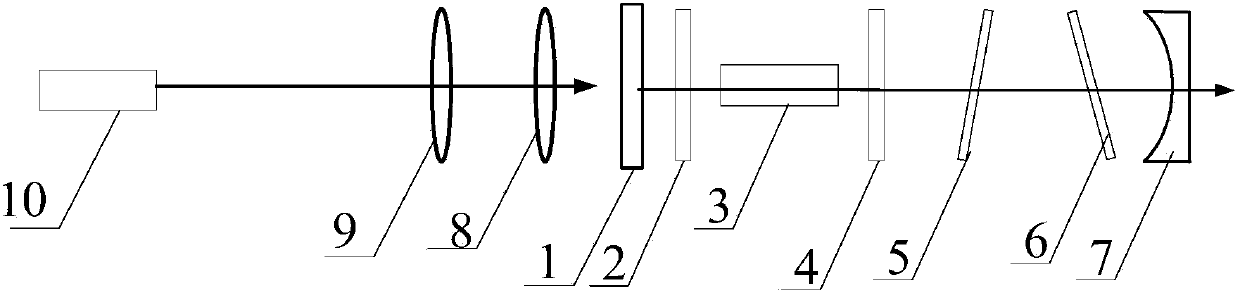

[0011] Specific implementation mode 1. Combination figure 1 Describe this embodiment mode, the Er:YAG torsional mode cavity tunable single longitudinal mode laser described in this embodiment mode, it comprises LD pump light generator 10, laser device input mirror 1, No. 1 quarter-wave plate 2, Er: YAG crystal 3, No. 2 quarter-wave plate 4, polarizing element 5, wavelength tuning element 6, laser output mirror 7 and pump light coupling system; the pump light coupling system includes No. 1 transformation lens 9 and No. 2 transformation lens 8;

[0012] The surface of the laser input mirror 1 is coated with a dielectric film with high transmittance of pump light and high reflection of oscillating light, and the surfaces of No. 1 conversion lens 9 and No. 2 conversion lens 8 are coated with a dielectric film with high transmittance of pump light. Both sides of No. 1 quarter-wave plate 2, No. 2 quarter-wave plate 4 and Er:YAG crystal 3 are coated with a dielectric film with high ...

specific Embodiment approach 2

[0016] Embodiment 2. The difference between this embodiment and the Er:YAG torsional cavity tunable single longitudinal mode laser described in Embodiment 1 is that the wavelength tuning element 6 uses a 1 mm thick F-P etalon.

specific Embodiment approach 3

[0017] Embodiment 3. This embodiment is a further description of the Er:YAG torsional cavity tunable single longitudinal mode laser described in Embodiment 1. The polarizing element 5 adopts a 0.5 mm thick F-P etalon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com