High-voltage frequency converter

A technology of high-voltage frequency converters and iron-core transformers, which is applied in the electric power field and can solve the problems of internal circuit short circuit, lack of automatic detection, and potential safety hazards of high-voltage frequency converters, and achieve the effects of long service life, wide application range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

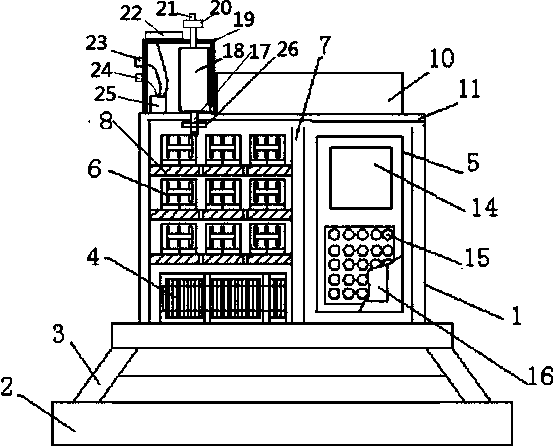

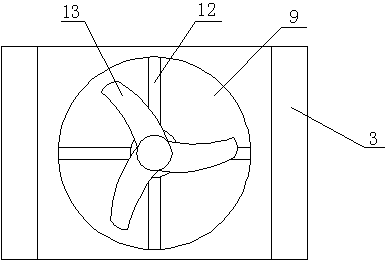

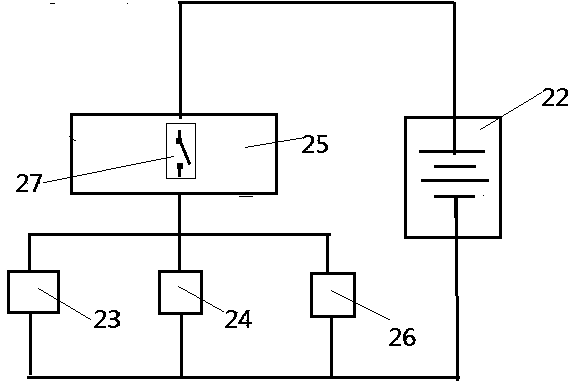

[0018] refer to figure 1 and figure 2 A high-voltage frequency converter shown includes a high-voltage frequency converter body (1), a base (2) and a support base (3), and an iron-core transformer (4) arranged in the high-voltage frequency converter body (1), and a set The control box (5) in the high-voltage inverter body (1), and the power unit (6) arranged in the high-voltage inverter body (1), the support base (3) is installed on the base (2), and the The high-voltage inverter body (1) is installed on the support base (3), and a vertical partition (7) is arranged inside the high-voltage inverter body (1), and the high-voltage inverter on the left side of the vertical partition (7) There are three transverse partitions (8) inside the body (1), the control box (5) is installed on the right side of the vertical partition (7), and the power unit (6) is installed on the three transverse partitions (8) Above, the iron-core transformer (4) is installed on the inner bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com