Circuit board connecting system

A circuit board insertion and circuit board technology, which is applied in the structural connection of printed circuits, printed circuit components, and electrical components to assemble printed circuits, etc., can solve the problem of reduced reliability, waste of circuit board retention resources, and high maintenance costs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

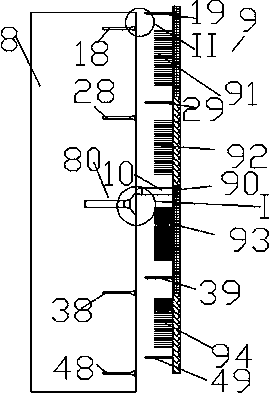

[0035] Combine below Figure 1-9 , the present invention is described in detail through the implementation of specific examples.

[0036]A circuit board plug-in system is characterized in that it includes a circuit board device 9 and a circuit board socket device 8, and the circuit board device 9 sequentially includes a first circuit board component 91, a second circuit board component 91, and a second circuit board assembly 9 from top to bottom in the longitudinal direction. The board part 92, the intermediate connecting part 90, the third circuit board sub-part 93 and the fourth circuit board sub-part 94, wherein the upper left side of the first circuit board sub-part 91 is provided with a first thin alignment pin 19 extending transversely to the left, the lower end It is detachably connected to the upper end of the second circuit board sub-component 92, and the left side of the first circuit board sub-component 91 is provided with a pin group extending transversely to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com