Marine vessel

A ship and hull technology, applied in ship propulsion, ship parts, ship construction, etc., can solve the problems of increased wind pressure resistance, decrease of ship speed, disturbance of air flow, etc., and achieve the effect of reducing wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the ship of the present invention will be described with reference to the drawings.

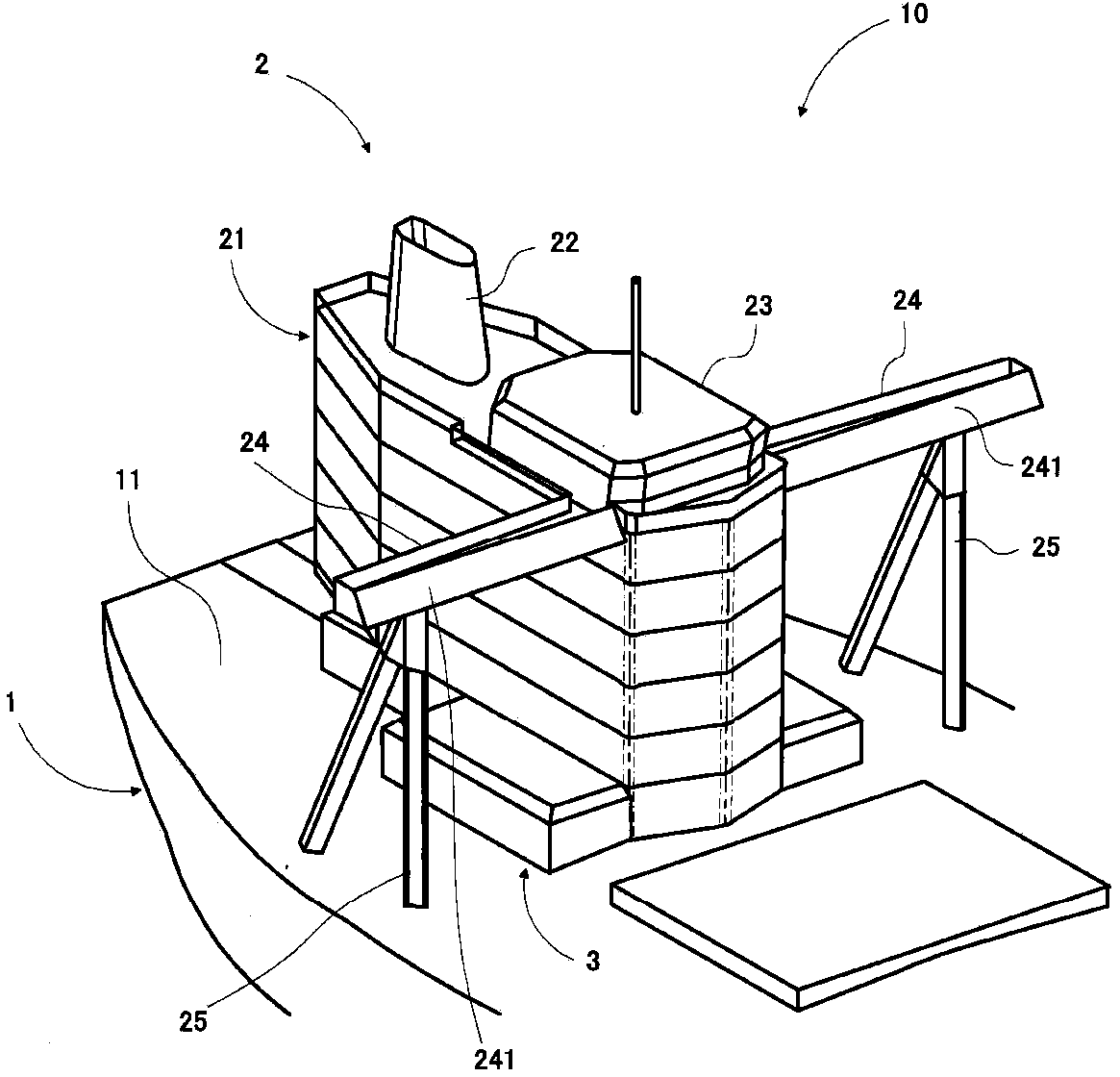

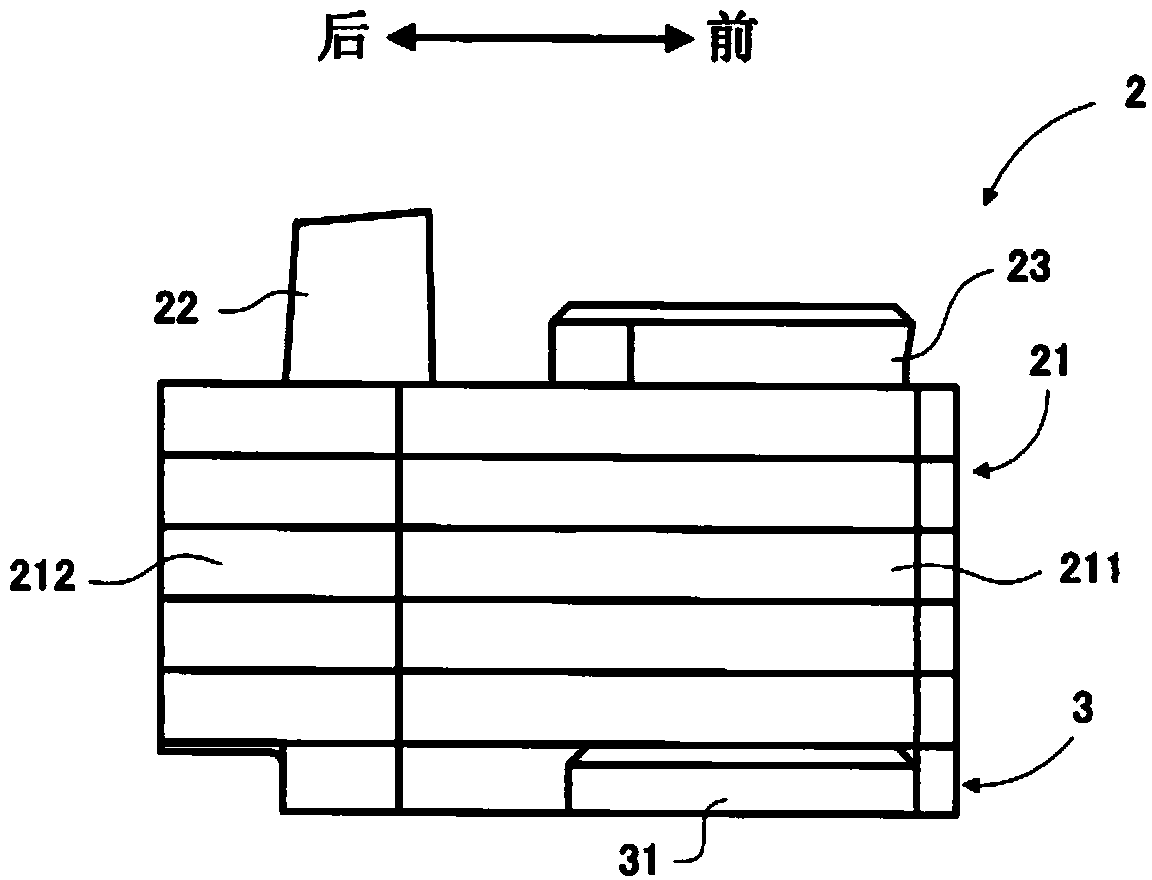

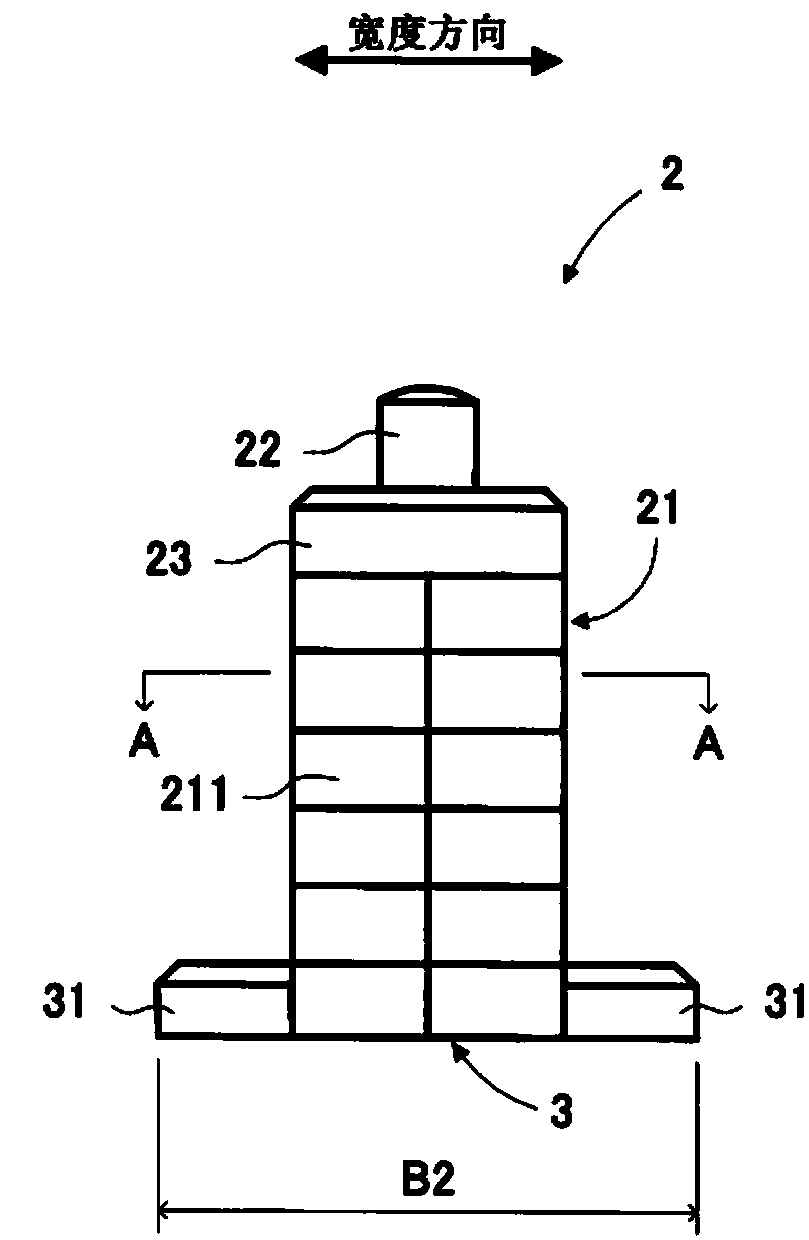

[0025] Such as figure 1 As shown, the ship 10 of the present embodiment includes a hull 1 and a first upper structure 2 provided on an upper deck 11 of the hull 1 via a second upper structure 3 . In addition, in this embodiment, for convenience of description, the bow side of the hull 1 is called "front", and the stern side is called "rear".

[0026] Such as figure 1 and figure 2 As shown, the first upper structure 2 includes a main body portion 21 including a living area 211 , and a machine room housing 212 adjacent to the rear of the living area 211 and integrally formed with the living area 211 . Additionally, if Figure 1 ~ Figure 3 As shown, the first superstructure 2 includes a chimney 22 and a bridge 23 provided on the main body 21 , and a bridge wing 24 provided on the side surface of the main body 21 .

[0027] In addition, from the viewpoint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com