Gas turbine power plant with non-homogeneous input gas

A technology for gas turbines and power stations, which is applied in gas turbine installations, flue gas combustion, combustion chambers, etc., and can solve problems such as incomplete combustion, high NOx emissions, and adverse effects on service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

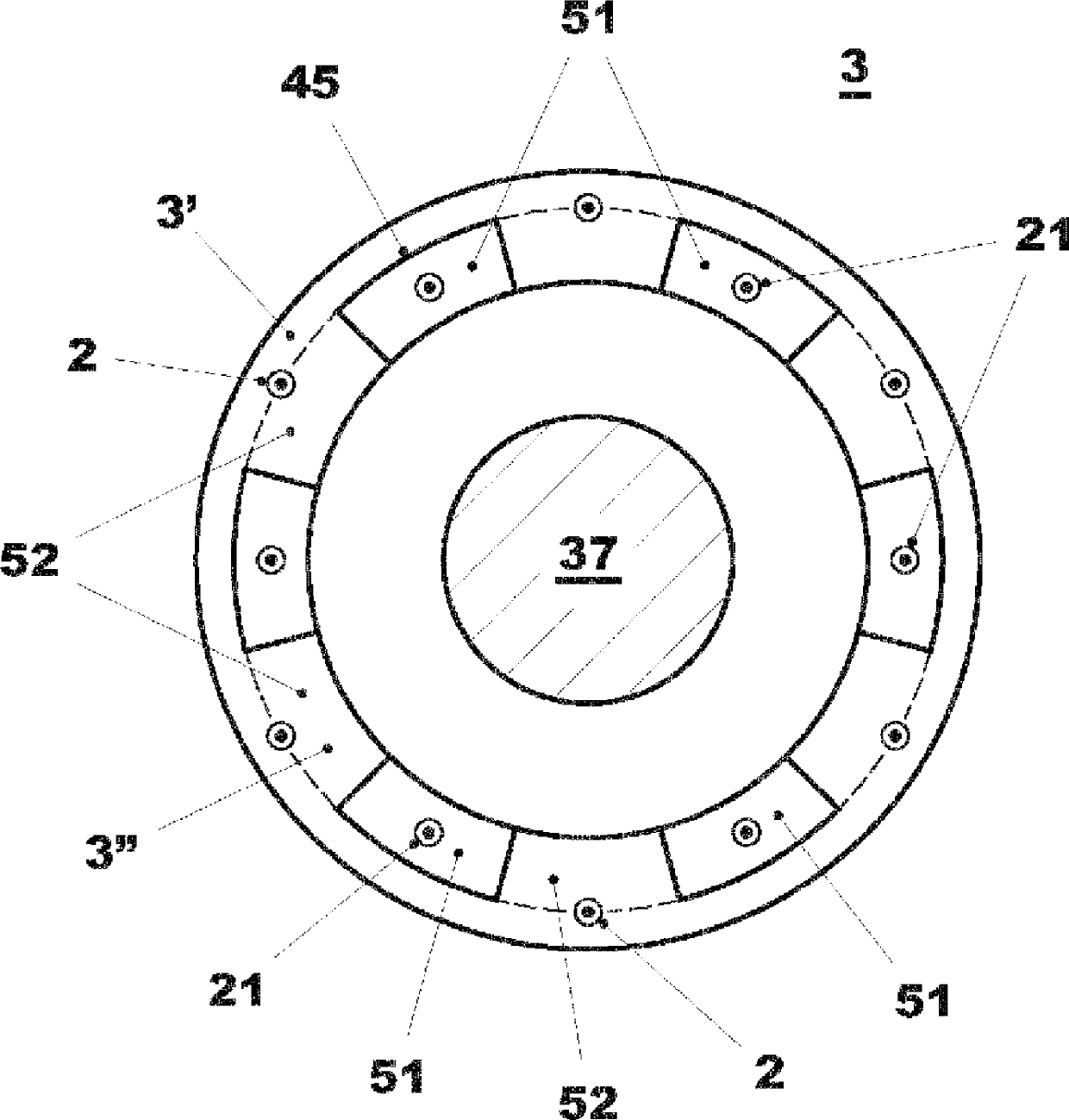

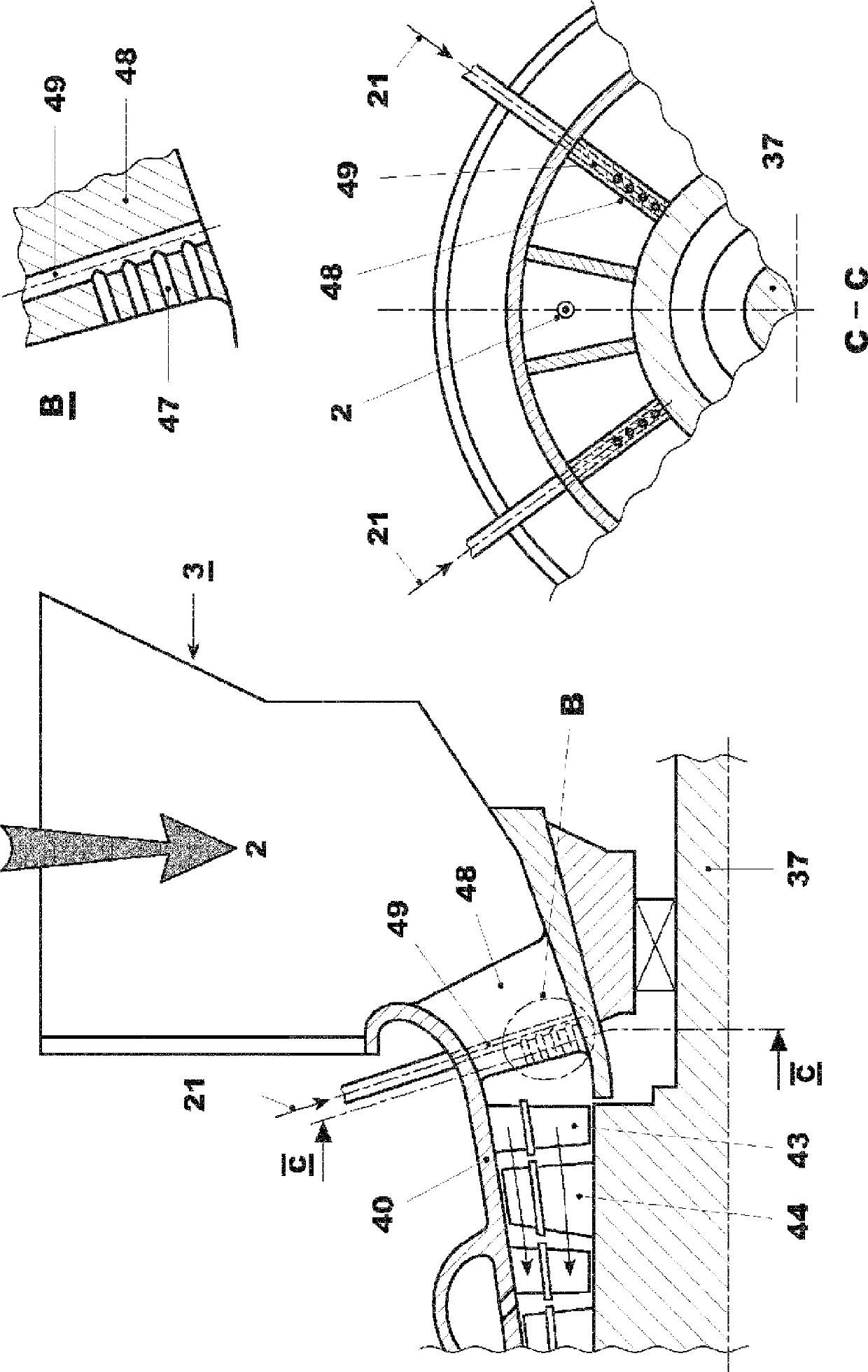

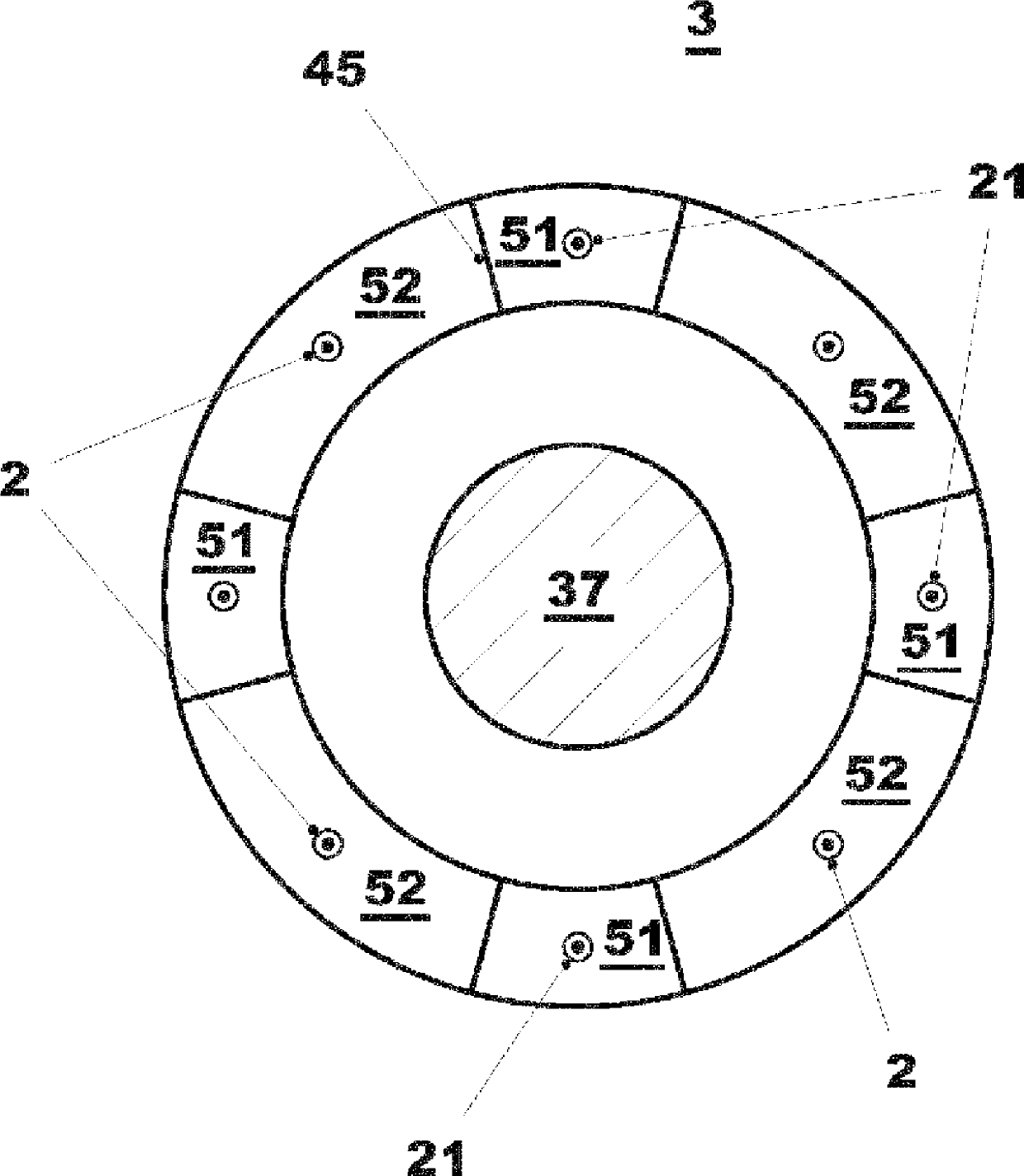

[0051] figure 1 The schematic diagram shows the necessary components of a gas turbine power station. The gas turbine 6 includes a compressor 1, and the combustion air compressed in the compressor 1 is supplied to the combustion chamber 4 and burned together with the fuel 5 there. The hot combustion gases then expand in the turbine 7. The usable energy generated in the turbine 7 is then converted into electrical energy by the first generator 25, for example, the first generator 25 is arranged on the same shaft 37.

[0052] In order to make best use of the energy still contained in it, the hot flue gas 8 discharged from the turbine 7 is used in the heat recovery steam generator (HRSG) 9 to generate fresh steam 30 for use in the steam turbine 13 or other devices . The usable energy generated in the steam turbine 13 is then converted into electrical energy, for example, by a second generator 26 which is arranged on the same shaft 37. The water-steam cycle is simplified in the exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com