Lens unit

A lens unit and lens technology, applied in optical components, instruments, manufacturing tools, etc., can solve the problems of lower yield, defective, difficult to control position, thickness, etc., and achieve high suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

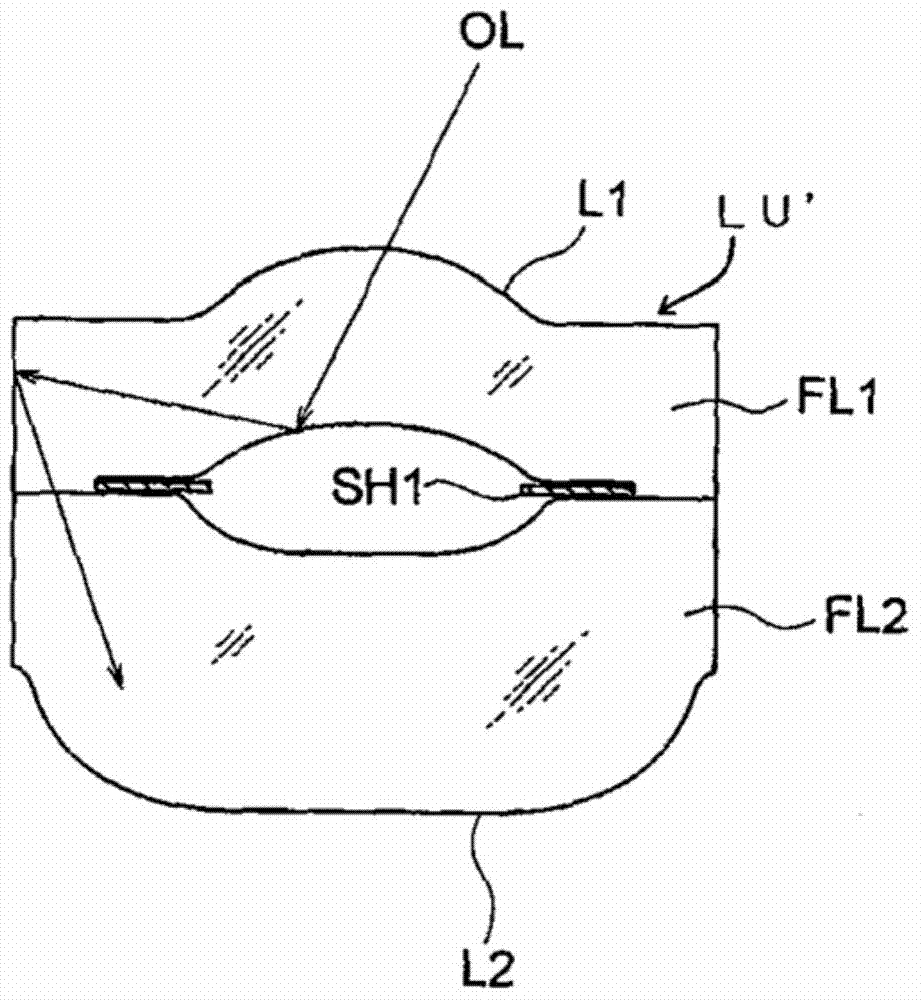

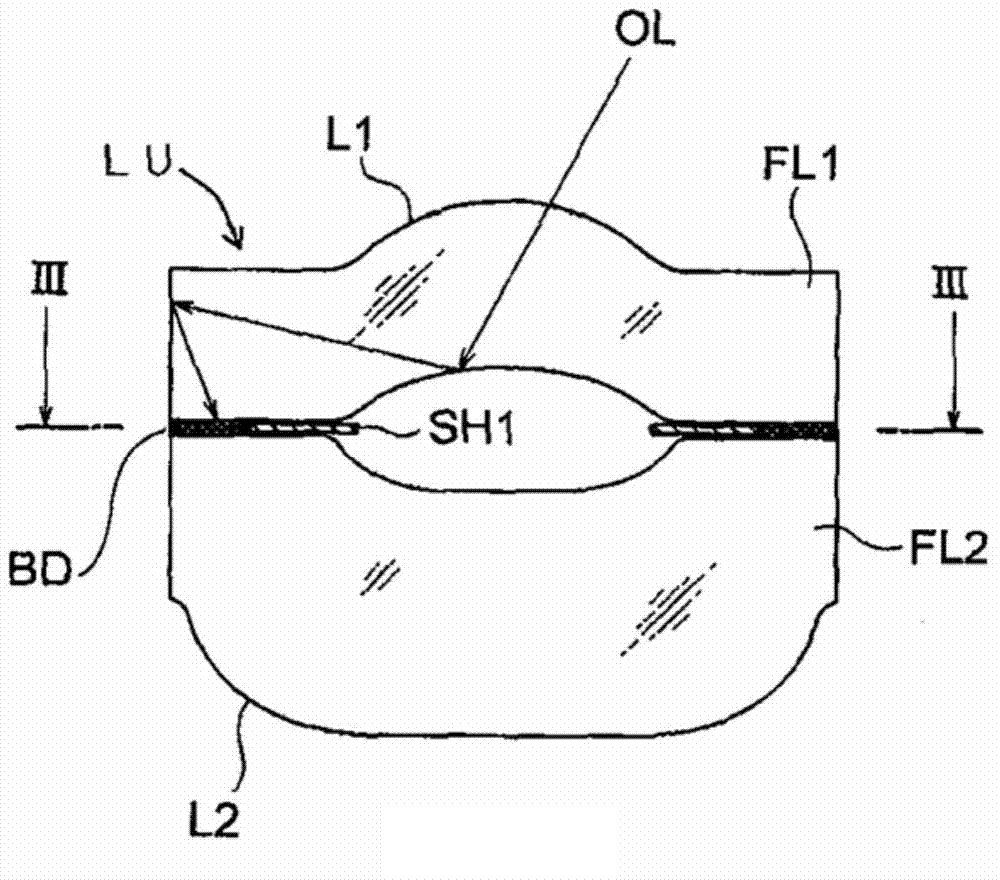

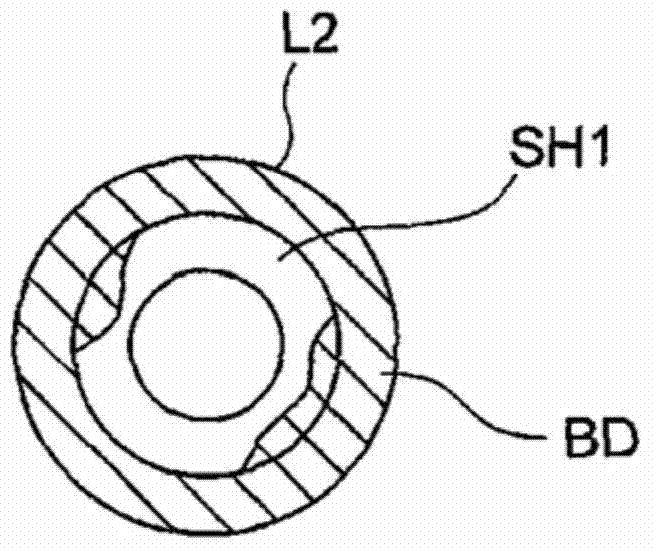

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 5 ~ Figure 8 It is a figure which shows the process of molding the lens array used in this embodiment using a molding die. On the lower surface 11 of the upper mold 10, four optical surface transfer surfaces 12 are protrudingly formed in two rows and two columns. The periphery of each optical surface transfer surface 12 forms a circular step portion 13 protruding from the lower surface 11 by one stage. The upper metal mold 10 can use hard and brittle materials that can also withstand glass forming, for example, materials such as cemented carbide and silicon carbide can be used. In addition, the same applies to the lower mold 20 described below.

[0051] On the other hand, on the upper surface 21 of the lower die 20, a substantially square flat blade land portion 22 is formed, and on the flat upper surface 23 of the flat blade land portion 22, depressions are for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com