Power module substrate with heat sink, and method for producing power module substrate with heat sink

A technology of a power module and a manufacturing method, which is applied in the field of manufacture of a substrate for a power module with a self-contained heat sink and a substrate for a power module with a self-contained heat sink, can solve the complex brazing operation and the reliability of bonding between a ceramic substrate and a metal plate. Problems such as drop, achieve the effect of excellent bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

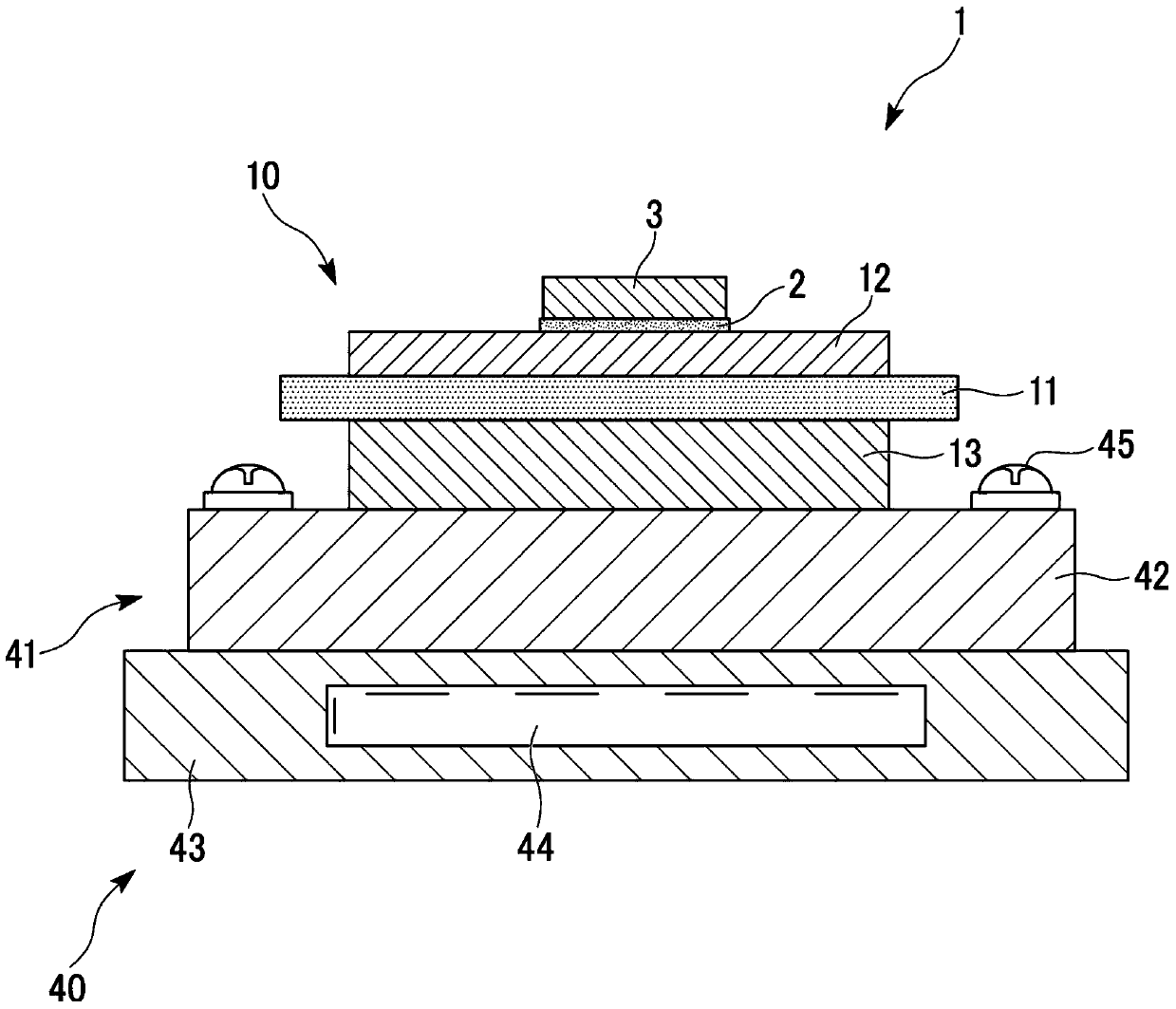

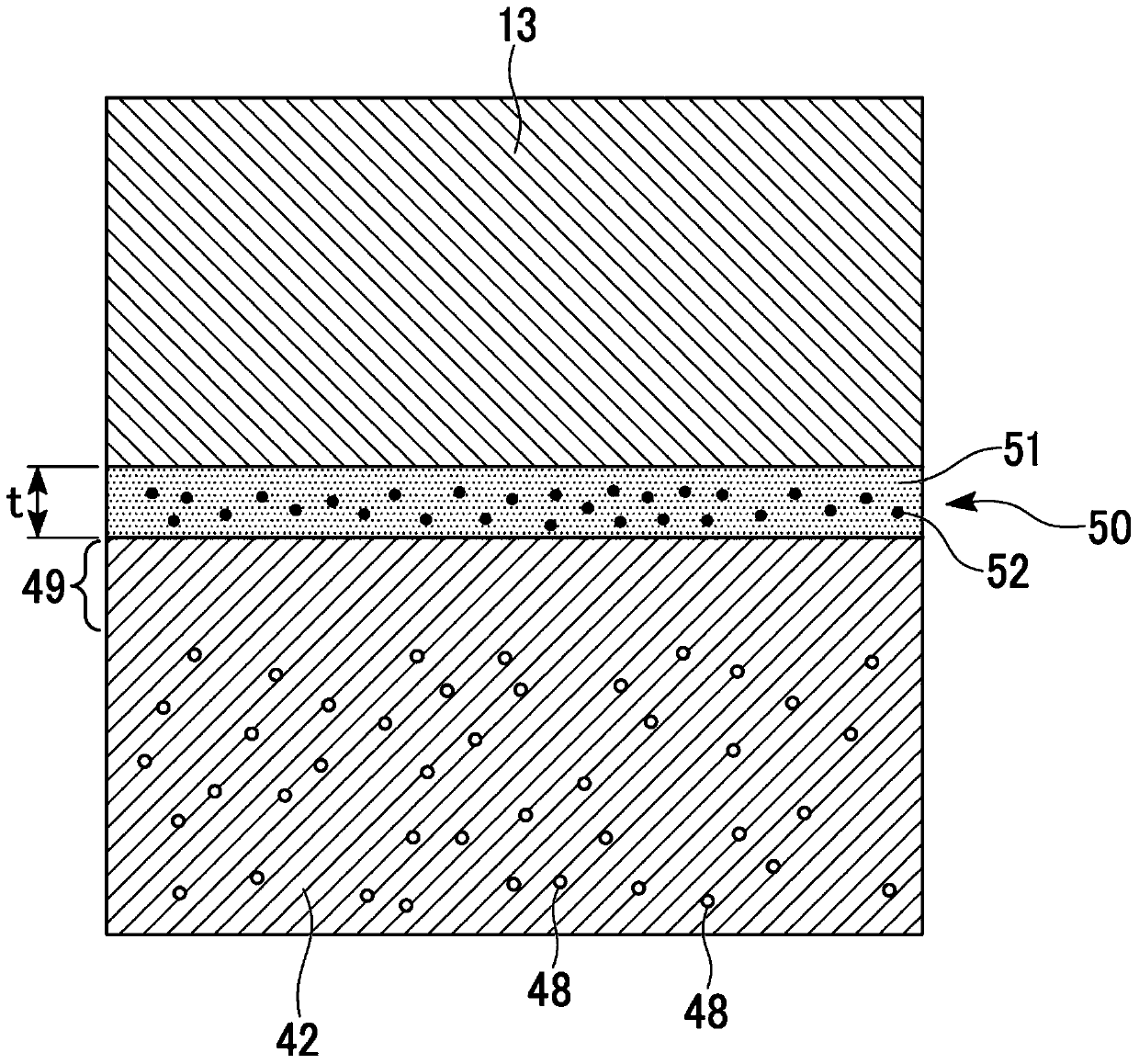

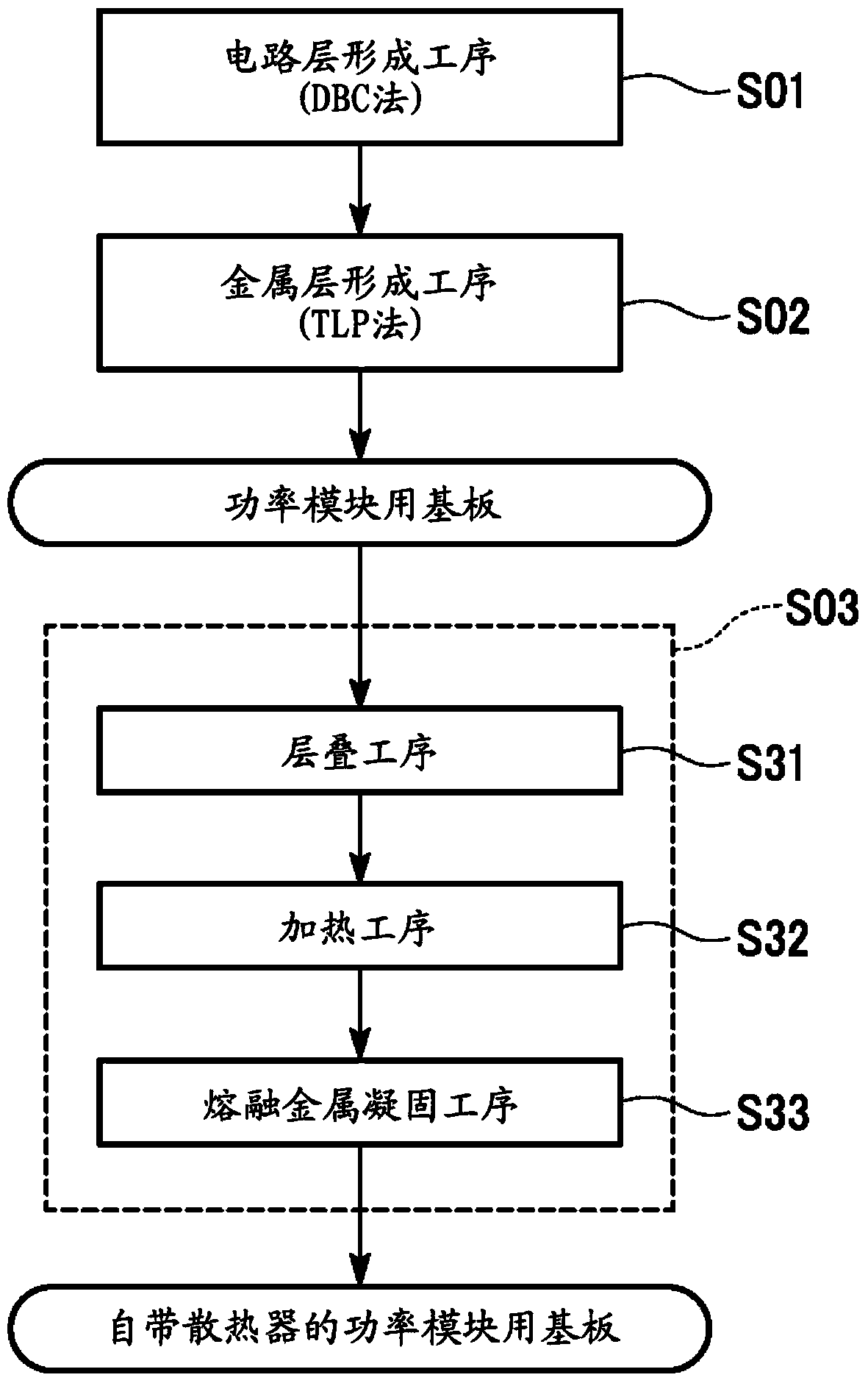

Examples

Embodiment

[0109] Hereinafter, the results of confirmation experiments conducted to confirm the effects of the present invention will be described.

[0110] As shown in Table 1, an insulating substrate, an aluminum plate as a circuit layer, and an aluminum plate as a metal layer were bonded to produce a power module substrate.

[0111] The bonding of the aluminum plate and the insulating substrate as the circuit layer, and the bonding of the insulating substrate and the aluminum plate as the metal layer was implemented under the following conditions. The aluminum plate as the circuit layer, the insulating substrate, and the aluminum plate as the metal layer are laminated through the solder foil of Al-10 mass % Si, and the aluminum plate is laminated at 5 kgf / cm in the lamination direction. 2 In a pressurized state, they were placed in a vacuum heating furnace and heated at 650° C. for 30 minutes to join them.

[0112] A1100 used for the metal layer in Table 1 is aluminum having an Al pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com