Glue filling device with high-speed rotation working platform

A working platform, high-speed rotation technology, applied in the device, packaging, transportation packaging and other directions of coating liquid on the surface, can solve the problems of low work efficiency and low product yield, achieve simple structure, high yield, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

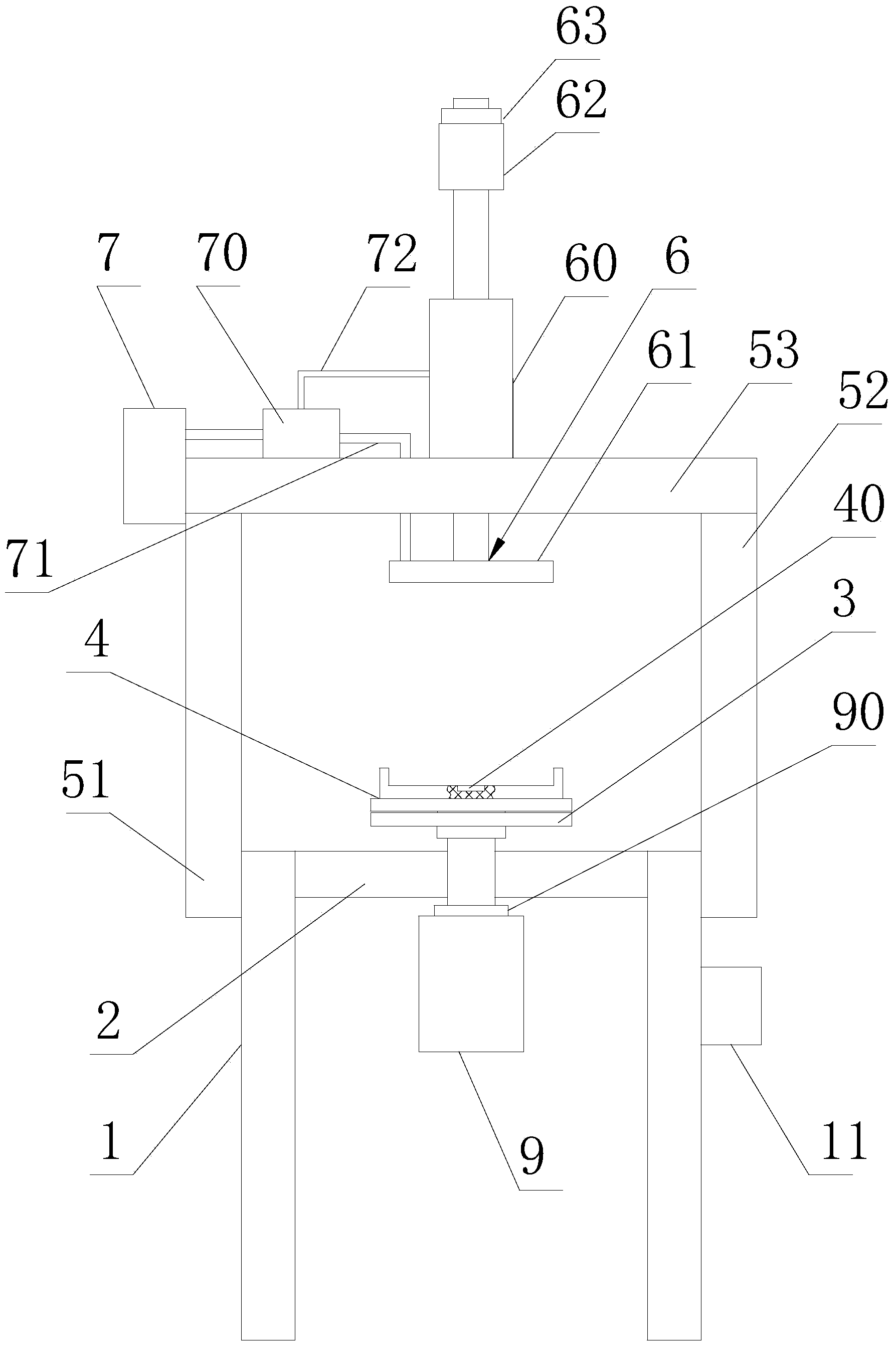

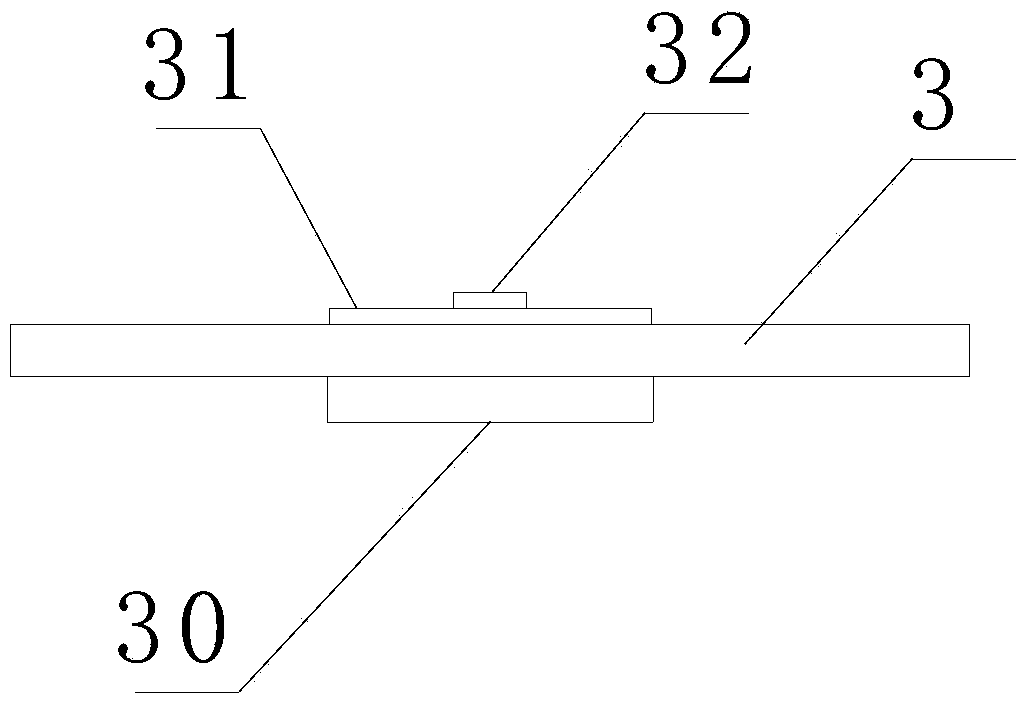

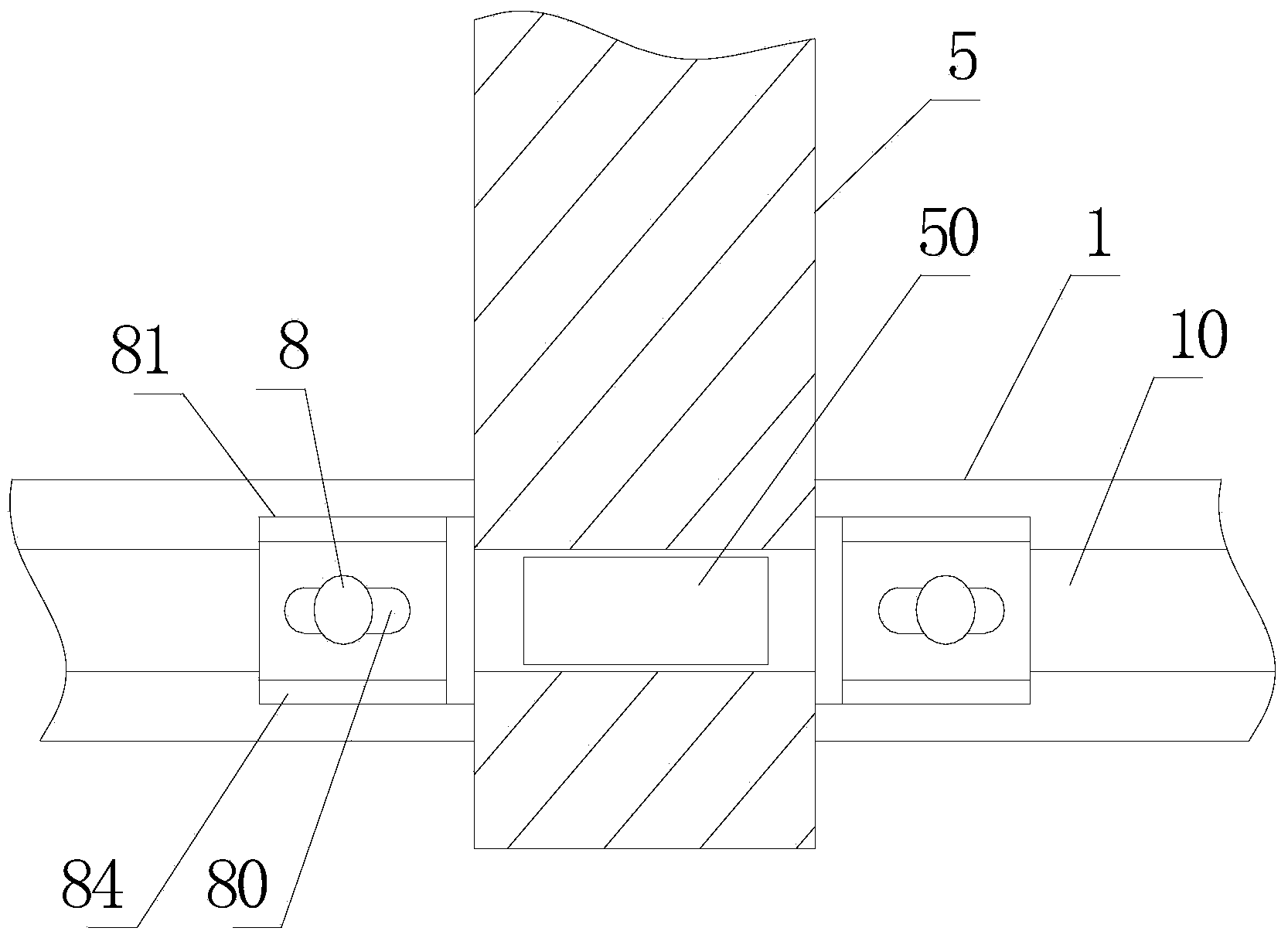

[0017] Such as figure 1 , figure 2 , image 3 As shown, a glue filling device with a high-speed rotating working platform includes a frame 1, a bottom plate 2 fixedly connected to the frame 1, at least one turntable 3 rotatably connected to the bottom plate 2, and a detachable turntable 3 The glue filling product 4 on the top, the middle part of the glue filling product 4 is provided with a glue filling hole 40 that is convenient for placing glue. Under the action of centrifugal force, it splashes around the glue filling product, which ensures the uniformity of glue application, facilitates glue discharge, and has a good effect. Along the horizontal direction of the bottom plate 2, a group of fixed components 5 are movably connected to the frame 1. The fixing assembly 5 includes a first column 51 and a second column 52 respectively movably connected to the frame 1, and a cross bar 53 for connecting between the first column 51 and the second column 52. There is a sealing as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com