Marking die with overload protection

An overload protection and mold technology, which is applied in the field of mechanical processing stamping molds, can solve the problems of mold damage, prone to stuffy cars, casualty accidents, etc., and achieve the effects of reducing product production costs, avoiding casualties, and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

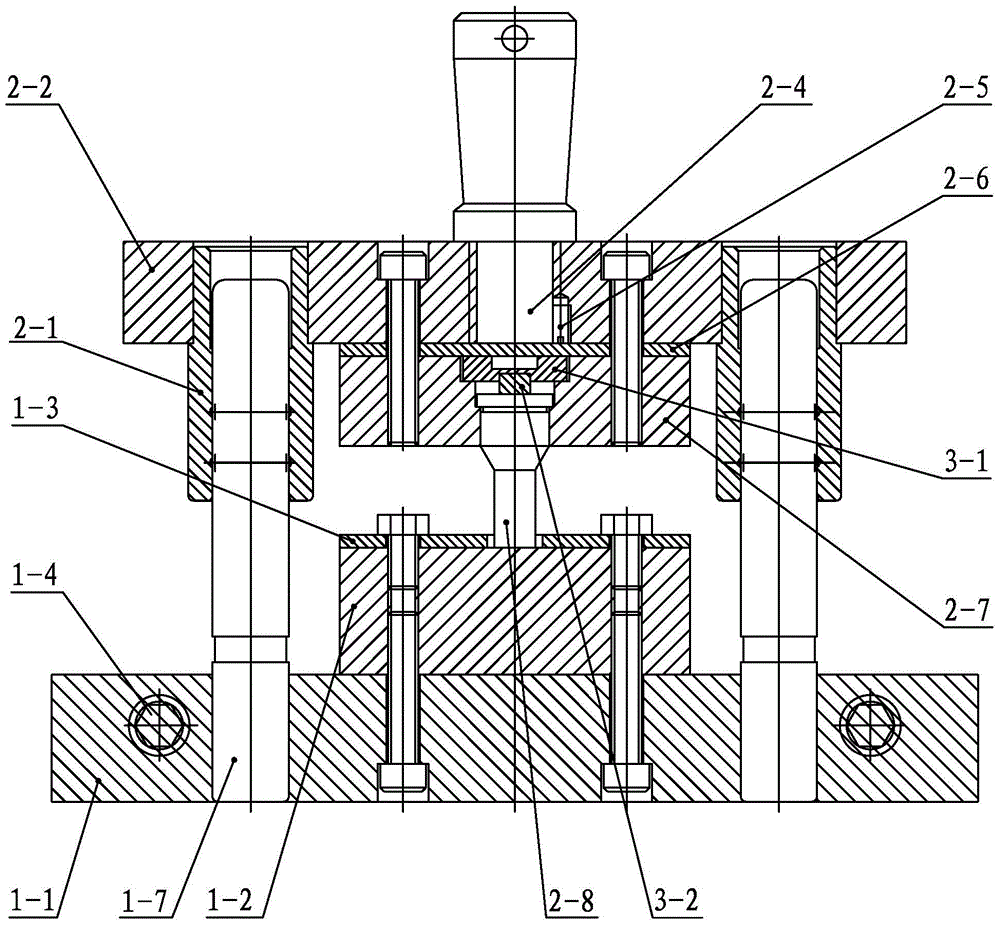

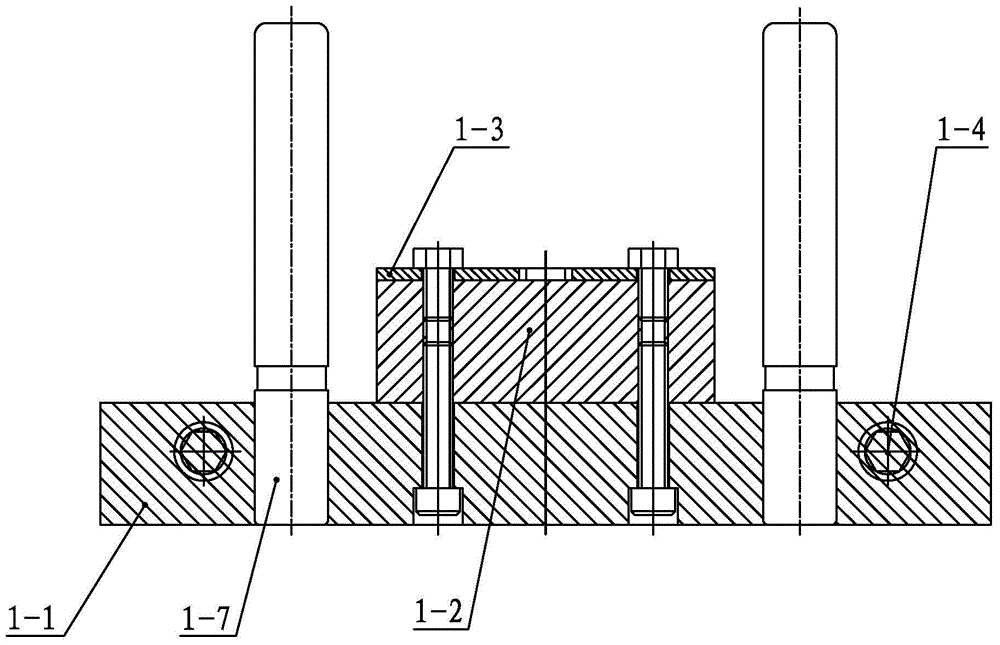

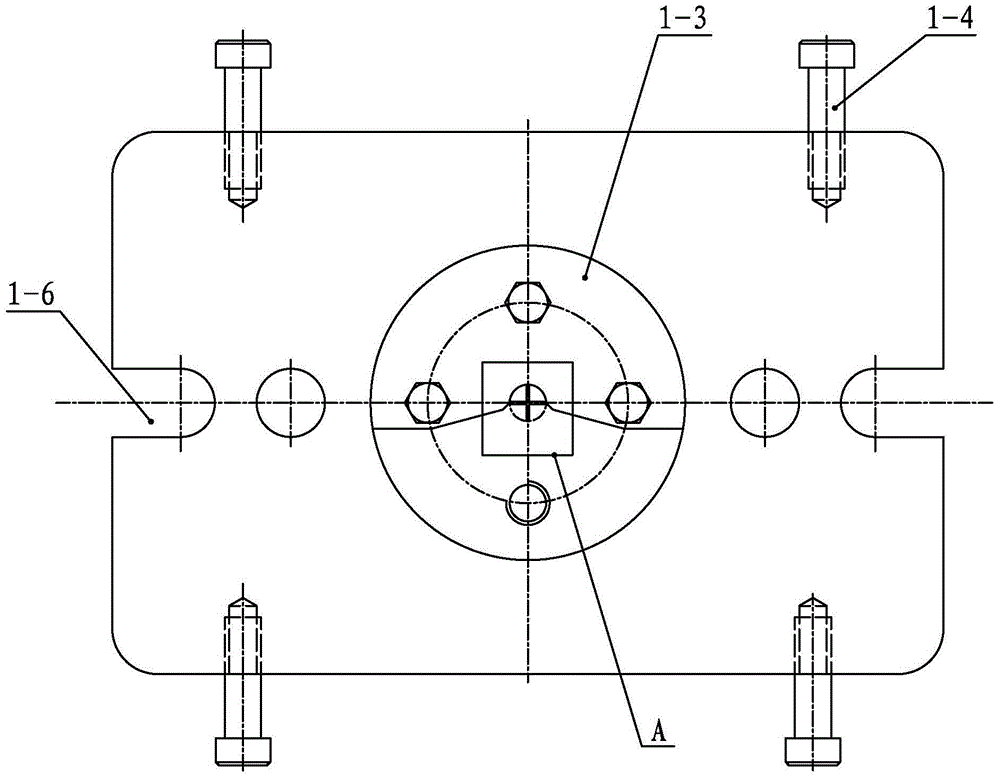

[0020] like Figure 1 to Figure 8 Shown, the engraving mold with overload protection device, it comprises upper mold assembly, lower mold assembly and overload protection device; Lower mold assembly includes lower template 1-1, lower mold 1-2, positioning plate 1-3 and Two guide pillars 1-7; the upper mold assembly includes an upper template 2-2, a mold handle 2-4, a backing plate 2-6, an upper mold fixing plate 2-7, an upper mold 2-8 and two guide sleeves 2 -1; the overload protection device includes a safety plate 3-1 and a safety pin 3-2; the lower mold 1-2 is arranged on the upper surface of the lower template 1-1, and the two are detachably connected; the middle part of the upper surface of the lower mold 1-2 There is a cross groove 1-5 for engraving a cross mark on the workpiece; the positioning plate 1-3 is arranged on the upper surface of the lower mold 1-2, and the two are detachably connected, and the cross of the positioning plate 1-3 and the lower mold 1-2 The cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com