Corrosion prevention method for margin plate of storage tank

A technology of edge boards and storage tanks, applied in the direction of adhesives, etc., can solve problems such as increased investment in manpower and material resources, safety problems of oil storage tanks, poor aging resistance, etc., to achieve convenient construction, simple structure, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

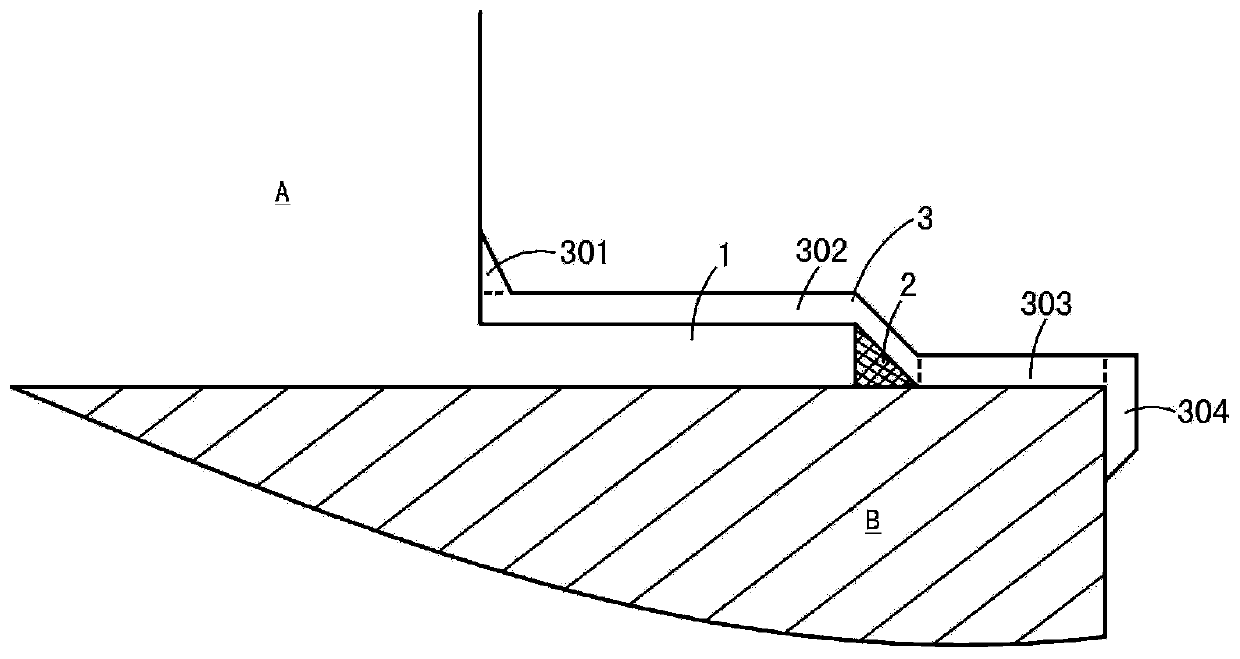

[0034] The invention provides an anticorrosion method for an edge plate of a storage tank, comprising:

[0035] Coating butyl viscoelastic anticorrosion paste at the lap joint of the edge plate and the abutment; and

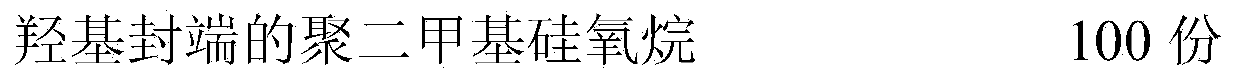

[0036] Silicone anticorrosion sealant is coated on the edge board and the butyl viscoelastic anticorrosion paste.

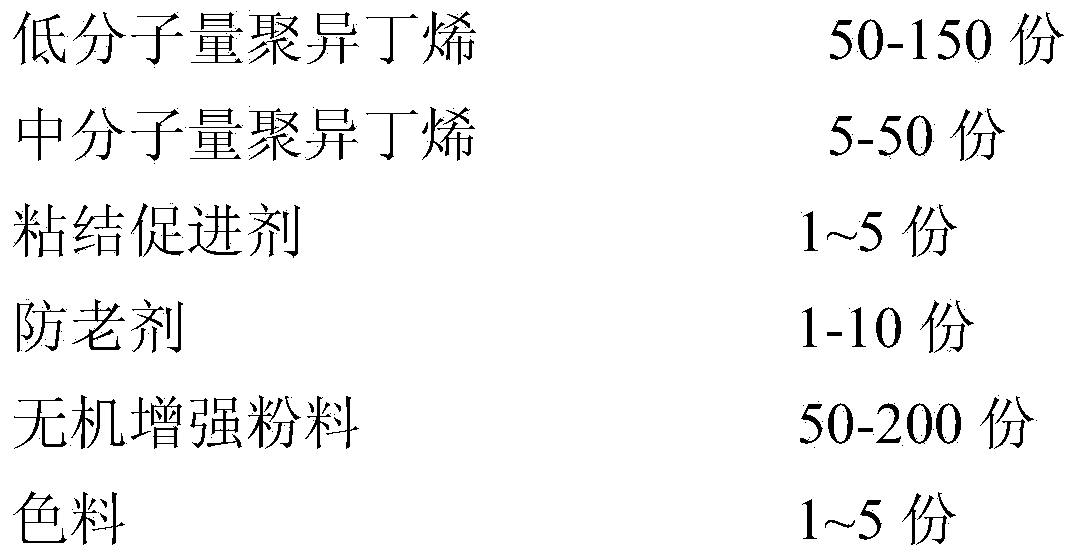

[0037] The raw materials of the butyl viscoelastic anticorrosion paste used in the present invention include polyisobutylene, adhesion promoter, inorganic reinforcing powder and anti-aging agent, etc., and its main technical indicators are as shown in Table 1.

[0038] Table 1: Main technical indicators of butyl viscoelastic anticorrosion pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com