Workshop sound-absorbing wall

A workshop, sound-absorbing cotton technology, applied in building components, layered products, buildings, etc., can solve the problems of poor low-frequency noise sound-absorbing effect, inability to take into account the dust reduction effect, and inability to have a good sound-absorbing effect, etc., to achieve the effect of reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

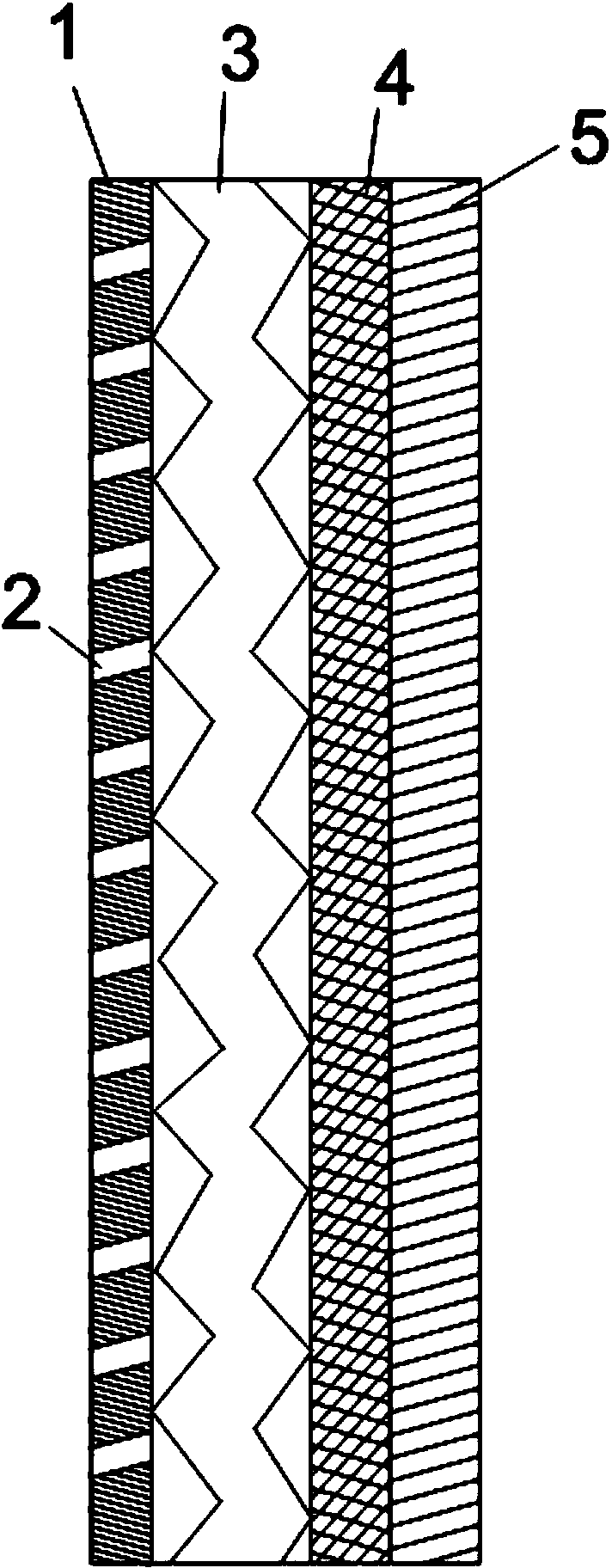

[0019] A workshop sound-absorbing wall, comprising a front plate 1, a sound-absorbing cotton layer 3, a sound-insulating foam 4, and a rear plate 5; the front plate 1, sound-absorbing cotton layer 3, sound-insulating foam 4, and the rear plate 5 overlap in sequence; the sound-absorbing cotton layer 3 is Wave-shaped, the curved part of the sound-absorbing cotton layer 3 forms a sound-absorbing cavity with the front pressure plate 1 and the sound-insulating foam 4 respectively;

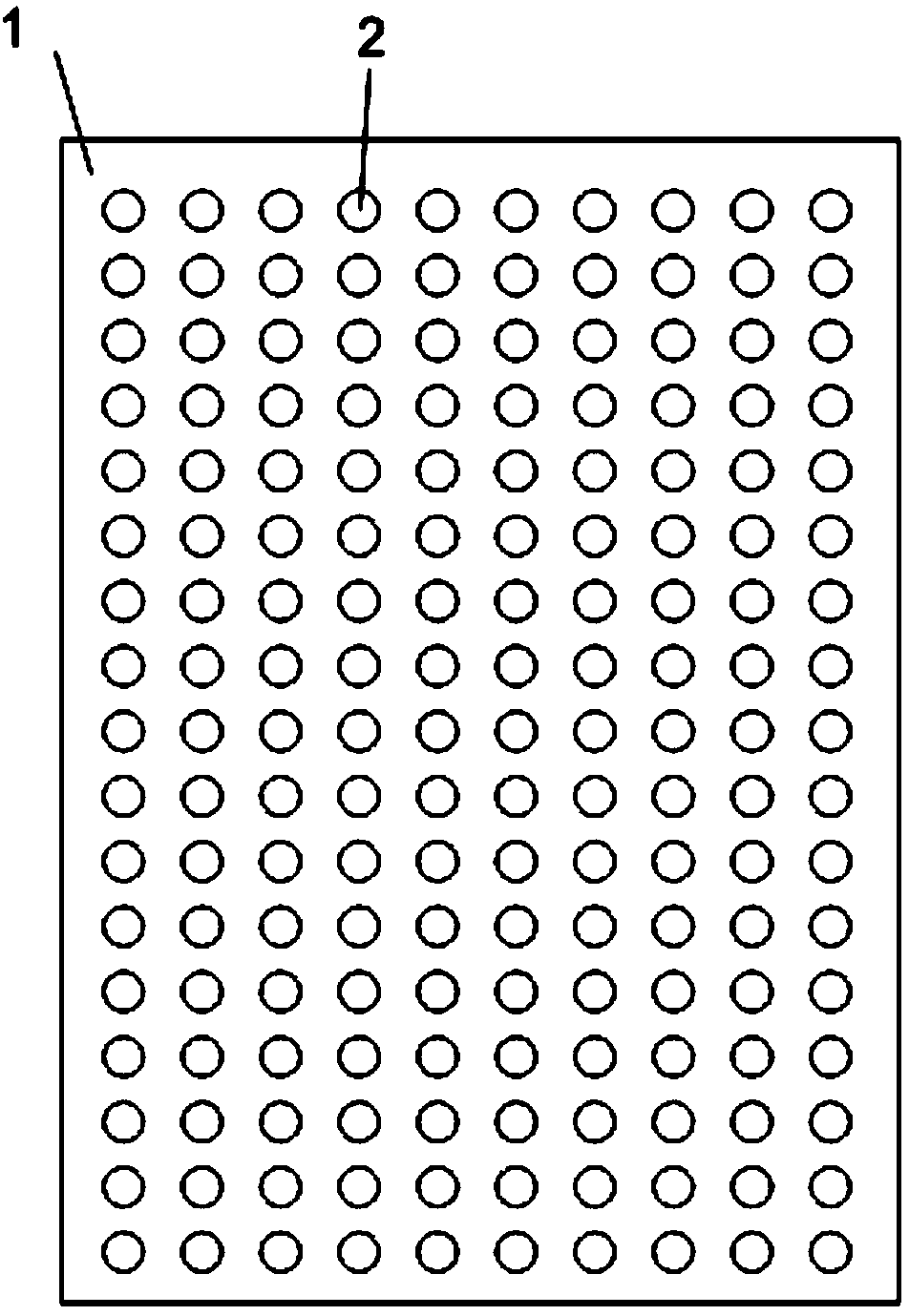

[0020] The preferred through holes 2 are arranged obliquely from top to bottom.

[0021] The preferred through-holes 2 are distributed in a rectangular shape on the front platen 1 .

[0022] When indoor noise is incident on the sound-absorbing wall, it enters the interior of the sound-absorbing wall through the porous front pressure plate, passes through the cavity, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com