Polyvinyl chloride solid wall pipe structure

A polyvinyl chloride, solid-wall pipe technology, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of poor sound insulation, poor flow diversion performance, and easy cracking of the pipe body, so as to achieve complete functions and reduce longitudinal cracks , the effect of not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

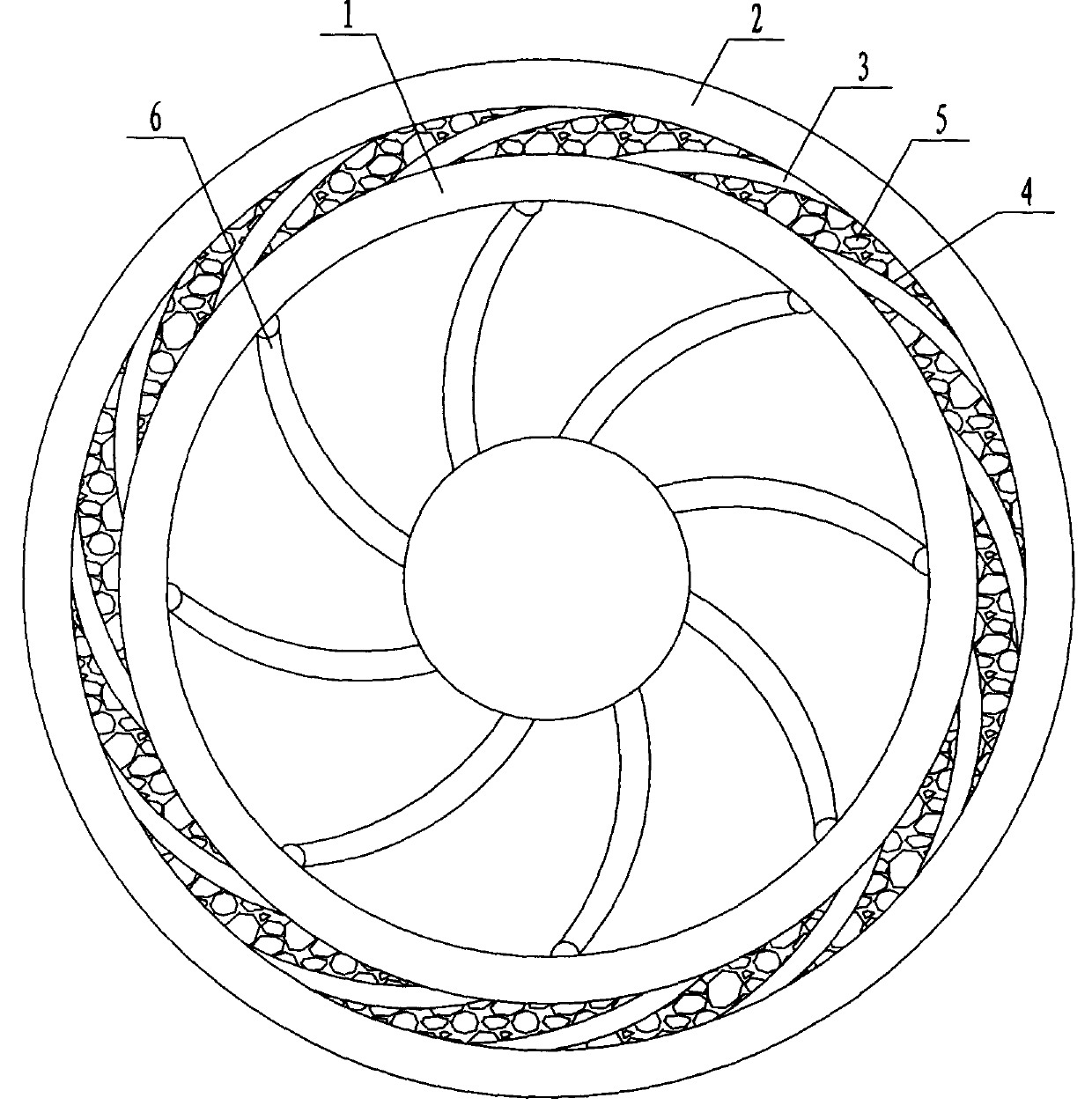

[0010] Such as figure 1 As shown, the polyvinyl chloride solid-wall pipe structure includes: an inner wall 1 and an outer wall 2, and the inner wall 1 and the outer wall 2 are connected into one body through several spiral support ribs 3, and the cavity 4 of the inner wall 1 and the outer wall 2 The inner wall is filled with sound-absorbing material 5, and eight spiral ribs 6 are arranged at equal intervals on the inner side of the inner wall 1.

[0011] Such as figure 1 As shown, in order to ensure the sound absorption effect, the sound absorption material 5 can be polyester fiber, straw wood, hole wood or regenerated wood.

[0012] Such as figure 1 As shown, in this example, in order to better buffer the longitudinal impact of the fluid on the pipe body, the eight helical ribs 6 have a circular arc structure.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com