Method and device for non-contact measurement of object volume based on mirror secondary imaging

A non-contact measurement and secondary imaging technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as being unsuitable for detecting large-scale objects, and can only measure the morphology of microscopic surfaces, so as to reduce the impact of ambient light. , The effect of stable measurement results and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

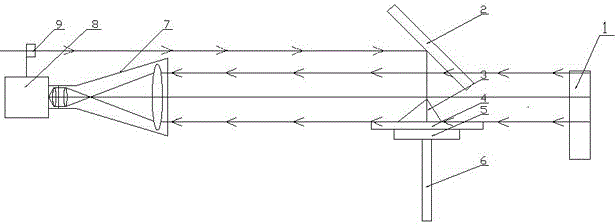

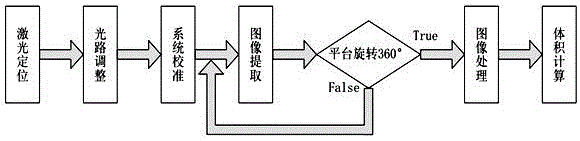

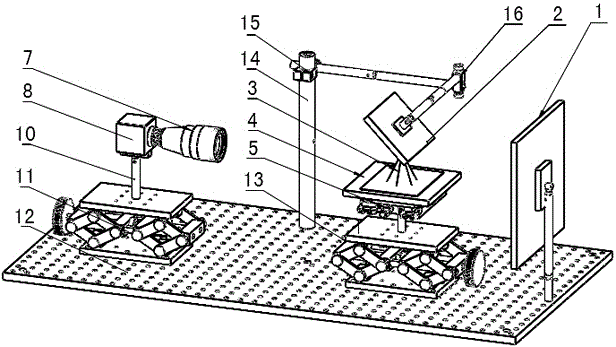

[0030] Such as Figure 1~7 As shown, a non-contact measuring device for object volume based on secondary imaging of a mirror includes a rotating stage 5 on which a first parallel light source 4 for placing an object to be measured 3 is laid flat, The center of the first parallel light source 4 coincides with the center of the rotating stage 5, and the top of the rotating stage 5 is provided with a plane reflector 2 with an angle of 45° with the vertical direction, and the rotating stage 5 A second parallel light source 1 is vertically arranged on one side of the rotating stage 5, and a double-sided telecentric lens 7 facing the second parallel light source 1 is arranged on the other side of the rotary stage 5, and the double-sided telecentric lens 7 is installed On the CCD camera 8, the optical axis of the CCD camera 8 is parallel to the upper surface of the rotary stage 5, and the top of the CCD camera 8 is provided with a laser beam that is horizontally emitted to the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com