Simple floating heat exchanger pressure test tool

A floating head heat exchanger and heat exchanger technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the waste of materials, increase the manufacturing cost, and the welding workload is large and other problems, to achieve the effect of reducing tooling costs, avoiding disassembly difficulties, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

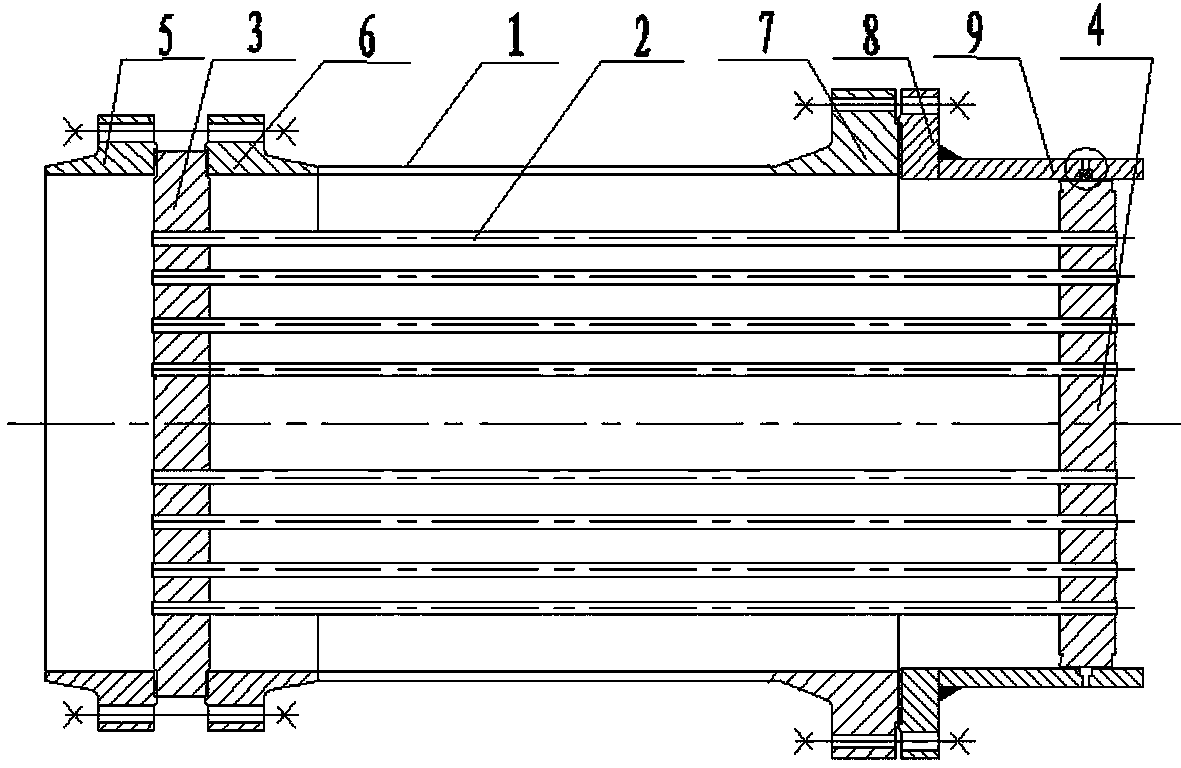

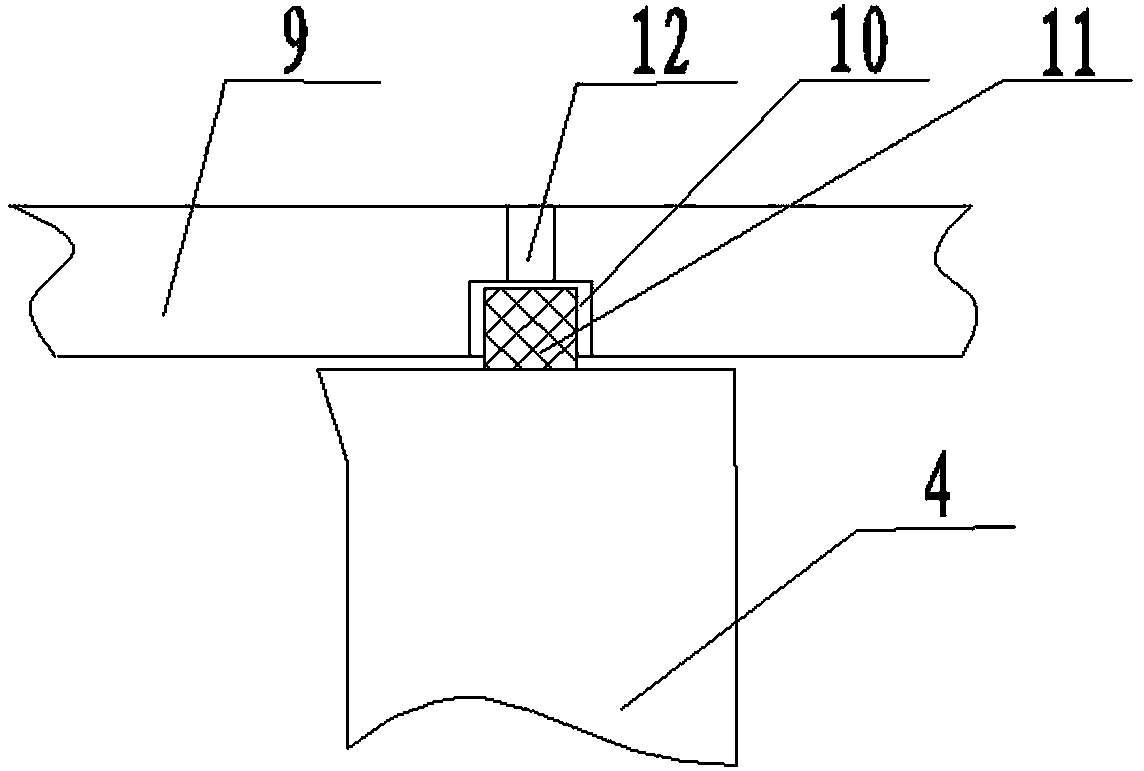

[0013] As shown in the figure, a simple floating head heat exchanger pressure test tool includes a heat exchanger cylinder 1, a fixed tube sheet 3, a floating tube sheet 4 and a heat exchange tube bundle 2 arranged in the heat exchanger cylinder 1, Among them, the two ends of the heat exchanger cylinder 1 are respectively welded with the tube box side flange 6 and the outer head cover side flange 7, the fixed tube sheet 3 and the floating tube sheet 4 are welded into an integrated structure through the heat exchange tube bundle 2, and the tube box is used The flange 5 and the tube box side flange 6 cooperate to fix the fixed tube plate 3 on one end of the heat exchanger shell 1, and the feature is that: the other end of the heat exchanger shell 1 is provided with a floating tube plate 4 The pressure test cylinder section 9 fixed inside it, and the pressure test cylinder section 9 cooperates with the outer head cover side flange 7 through the tooling flange 8 provided on it to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com