Anti-dazzling hard coating

An anti-glare and hard coating technology, which is applied in coatings, nonlinear optics, instruments, etc., can solve problems such as difficulty and good writing, and achieve the effect of good writing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

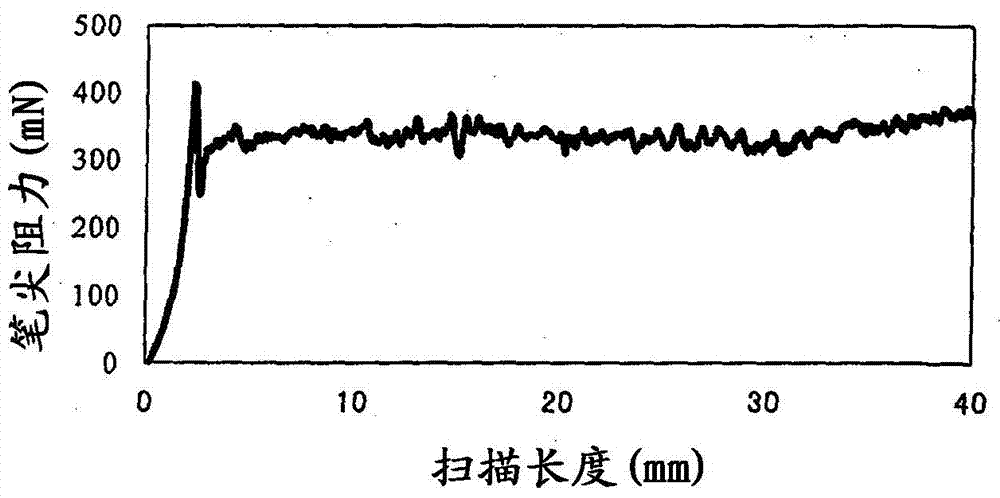

Embodiment 1

[0101] 100 parts by mass of dipentaerythritol hexaacrylate (manufactured by Shin-Nakamura Chemical Industries, NK Ester A-DPH) as a polyfunctional (meth)acrylate (expressed in terms of solid content. Hereinafter, the same applies to other components.); 4.3 parts by mass of 1-hydroxycyclohexyl phenyl ketone (manufactured by BASF Corporation, Ilgakyua 184) as a photopolymerization initiator; silica microparticles (manufactured by Fuji Silicone Chemical Co., Ltd., Cyclohobic 702); average particle diameter: 4.1 μm, CV value 48%, amorphous) 11 parts by mass; 0.01 parts by mass of polydimethylsiloxane (manufactured by Toray Dou Corning Co., SH28) and silica nanoparticles (manufactured by Nissan Chemical Industry Co., Ltd., MIBK) as a leveling agent -ST, average particle diameter: 10 nm) 8.3 parts by mass were mixed to obtain a coating composition. This coating composition was diluted with propylene glycol monomethyl ether to prepare a coating liquid having a solid content concentra...

Embodiment 2

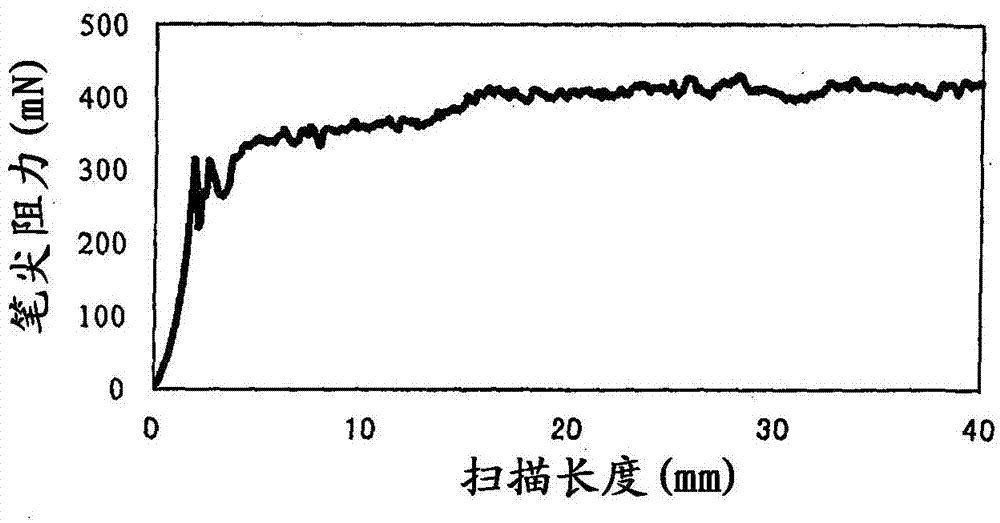

[0110] Except having changed the compounding quantity of a leveling agent into 0.14 mass part, and having formed an anti-glare hard-coat layer, it carried out similarly to Example 1, and produced the anti-glare hard-coat film.

Embodiment 3

[0112] Except having changed the compounding quantity of a leveling agent into 0.70 mass part, and having formed an anti-glare hard-coat layer, it carried out similarly to Example 1, and produced the anti-glare hard-coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com