Method and device for processing carbon fiber overhead transmission lines

An overhead transmission line and carbon fiber technology, which is applied to circuits, electrical components, marking conductors/cables, etc., can solve problems such as the difficulty of carbon fiber overhead transmission lines, and achieve the effects of simple structure, improved production efficiency, and ingenious ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

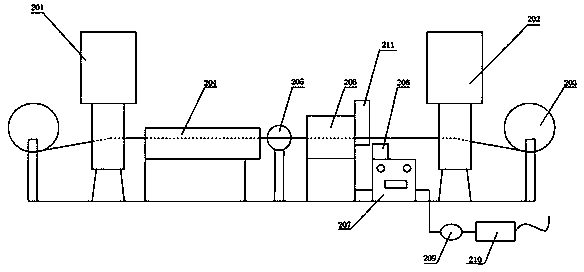

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0016] like figure 1 Shown, the processing method of carbon fiber overhead power transmission line, comprises the following steps:

[0017] Step 1. Cooling: Lead the carbon fiber overhead transmission line processed from the cable extruder into the cooling water tank for cooling. The temperature of the cooling water in the cooling water tank is 10-20 °C;

[0018] Step 2. Blowing water: Blow the carbon fiber overhead transmission line cooled in the cooling water tank with a water blower to dry the water on the carbon fiber overhead transmission line to prevent discoloration and corrosion;

[0019] Step 3. On-line power frequency withstand voltage test: carry out the withstand voltage test on the carbon fiber overhead transmission line through the power frequency withstand voltage test device, and find the carbon fiber overhead transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com