Multi-parallel capacity optimal distributing method for active harmonic suppression device

A harmonic control and capacity optimization technology, applied in active power filtering, AC network to reduce harmonics/ripples, etc., can solve the problems of low utilization rate of the compensation capacity of the whole machine, lack of coordination of power units, poor scalability, etc. , to achieve maximum utilization, avoid hardware aging, and speed up response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

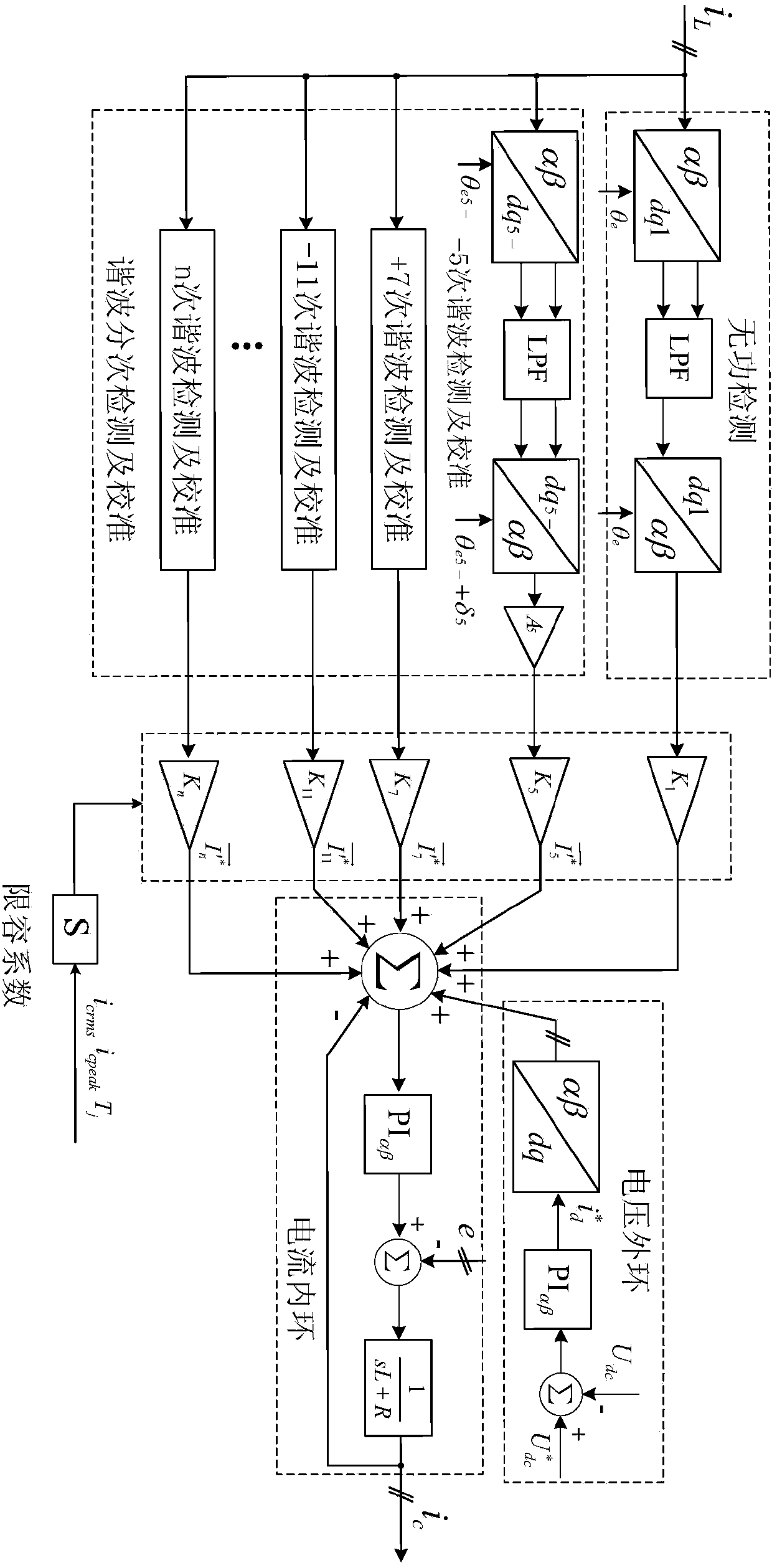

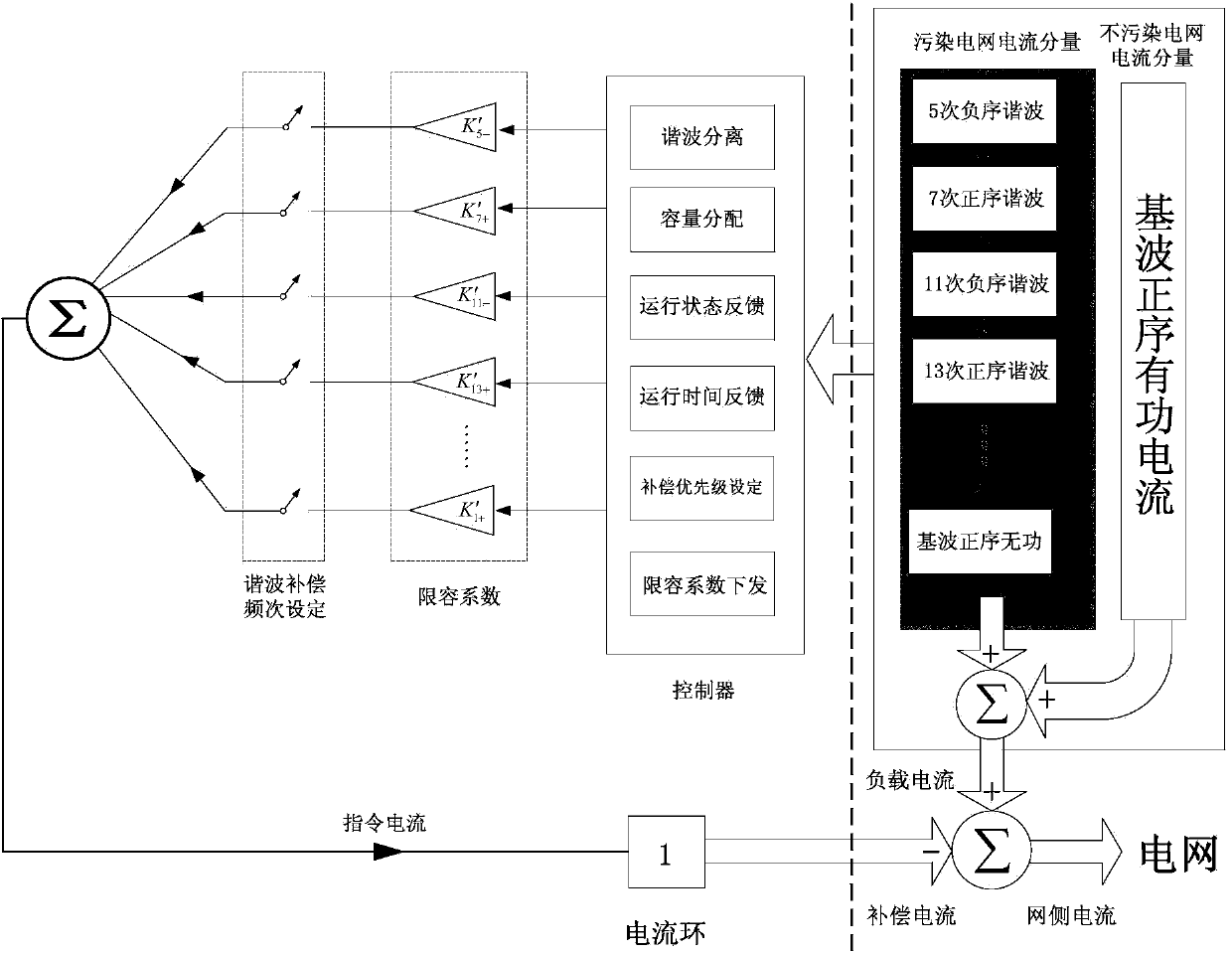

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

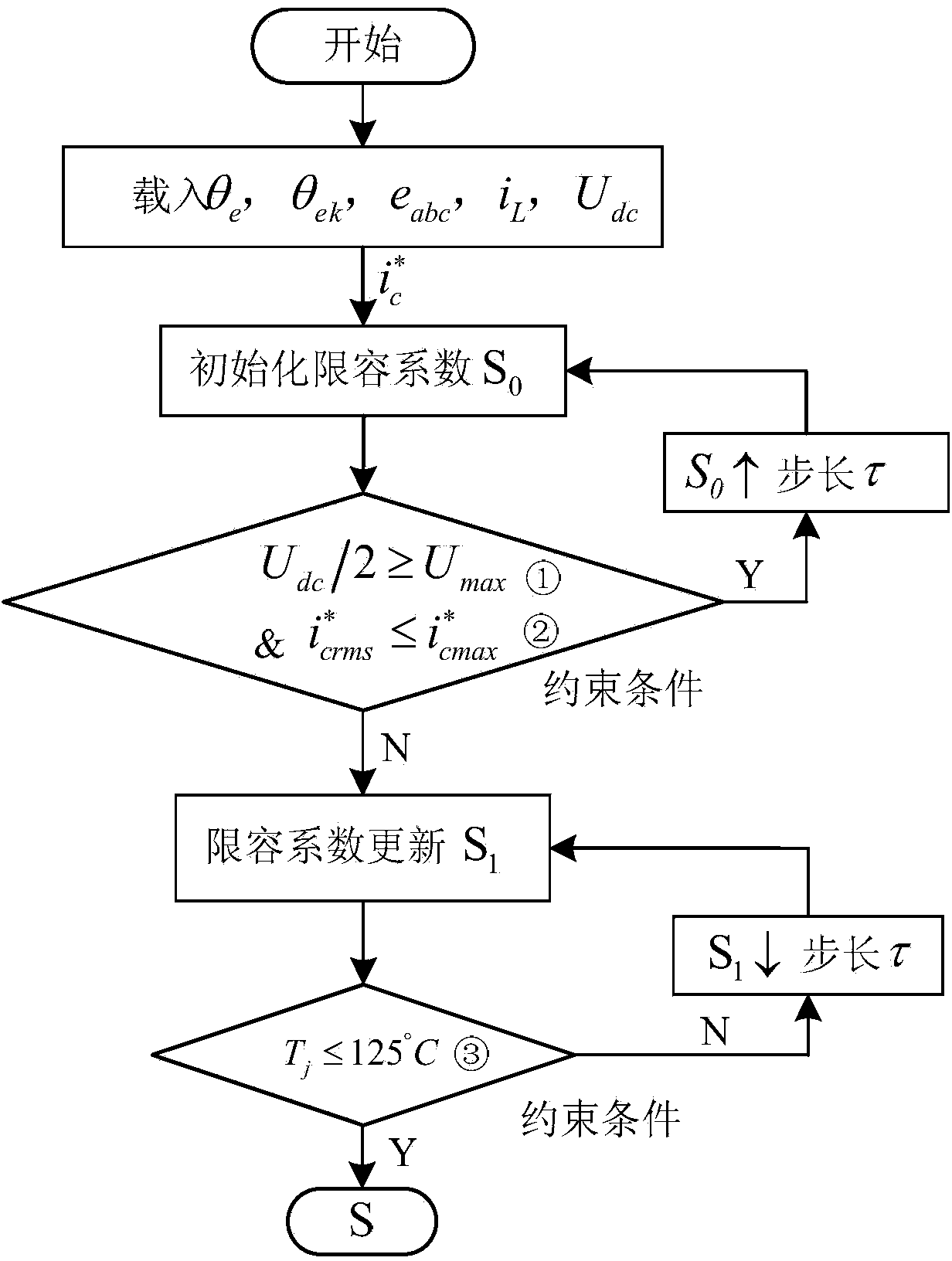

[0053] An optimal allocation method for multi-machine parallel connection capacity of an active harmonic control device, which adopts multi-machine redundancy and a master-slave control structure. Transmitting and carrier phase shifting, while the upper master controller is also responsible for receiving the operating state command of the power unit and the compensation capacity of the power unit sent by the slave controller of the lower layer, and the slave controller of the lower layer is responsible for the independent control of harmonics;

[0054] When the harmonic capacity is less than the parallel capacity, the whole machine runs in redundant mode, and the compensation capacity is allocated according to the principle of minimizing the number of power units in operation, and when the running time of a certain power unit exceeds the preset value, the upper-level ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com