Inspection apparatus and method

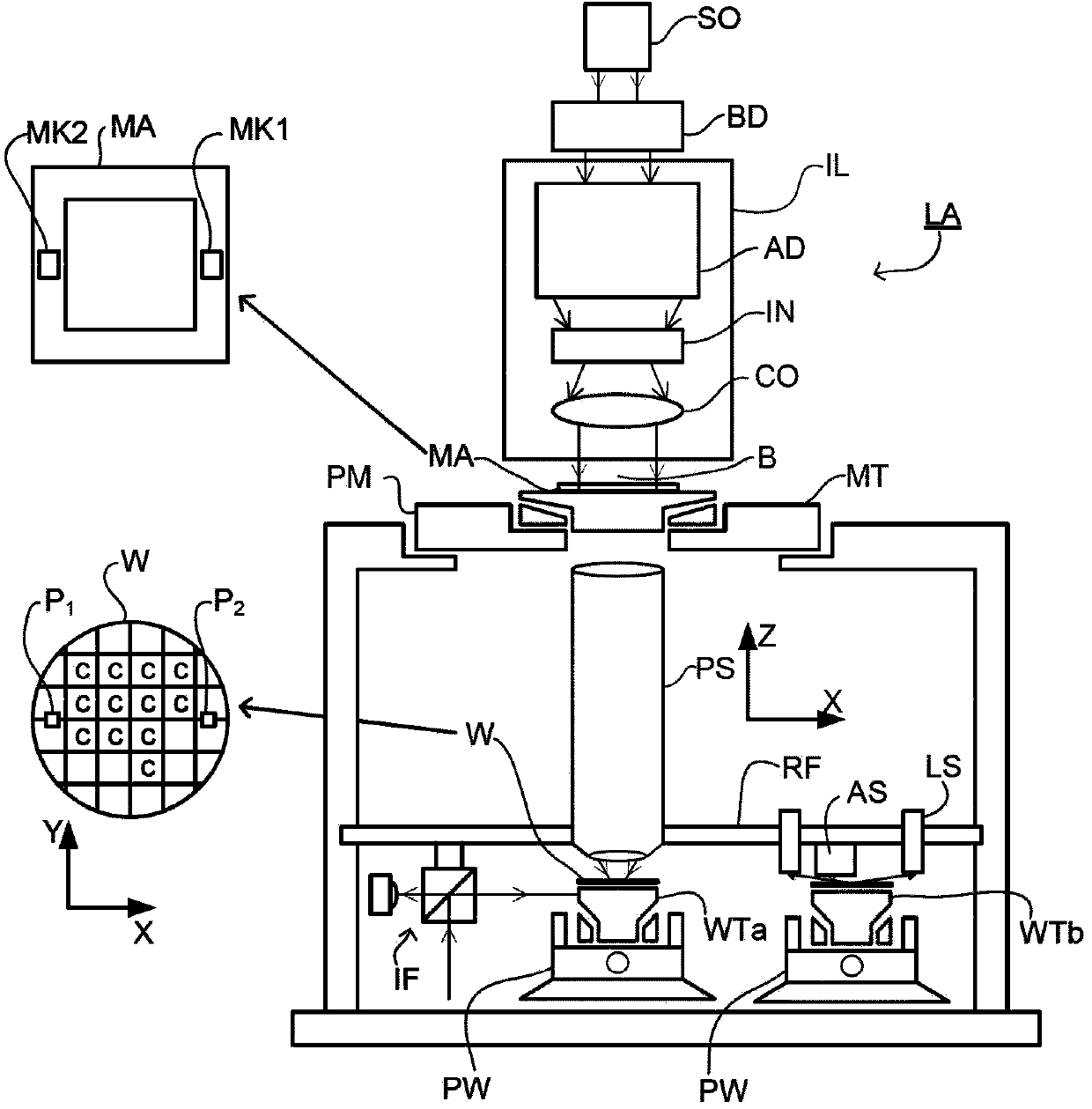

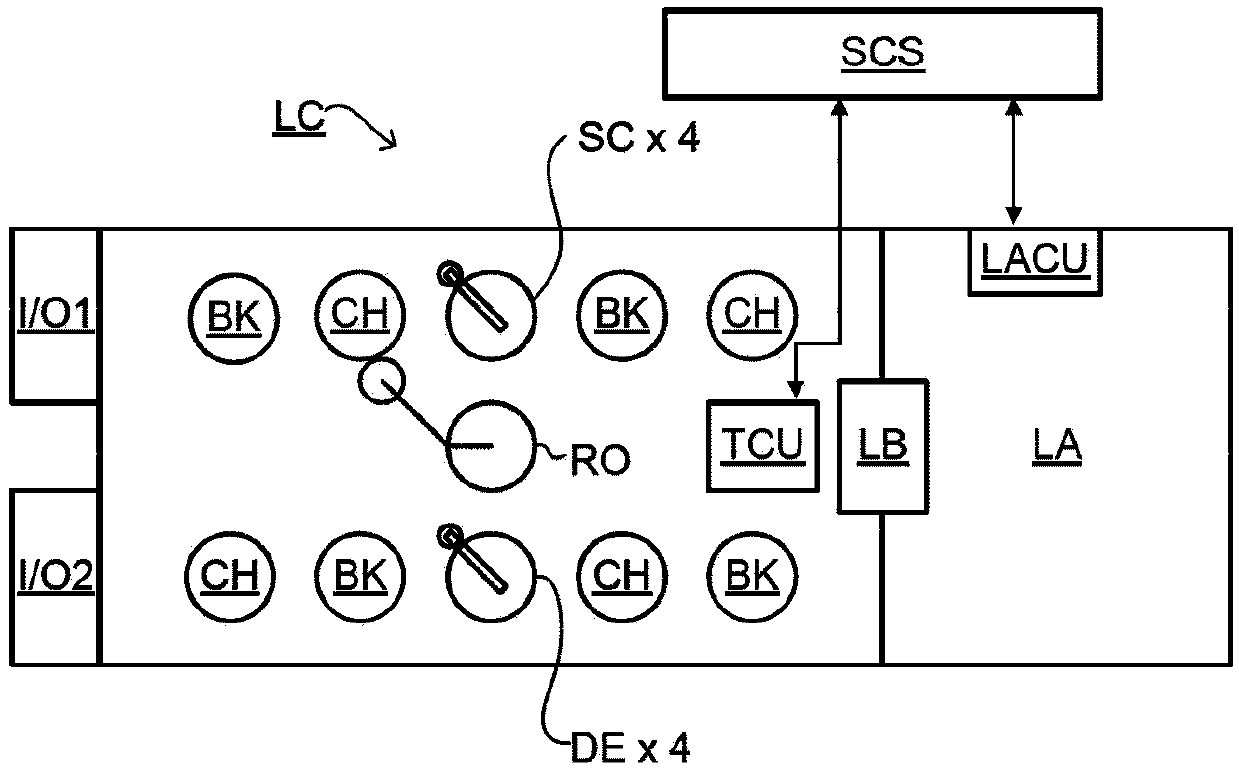

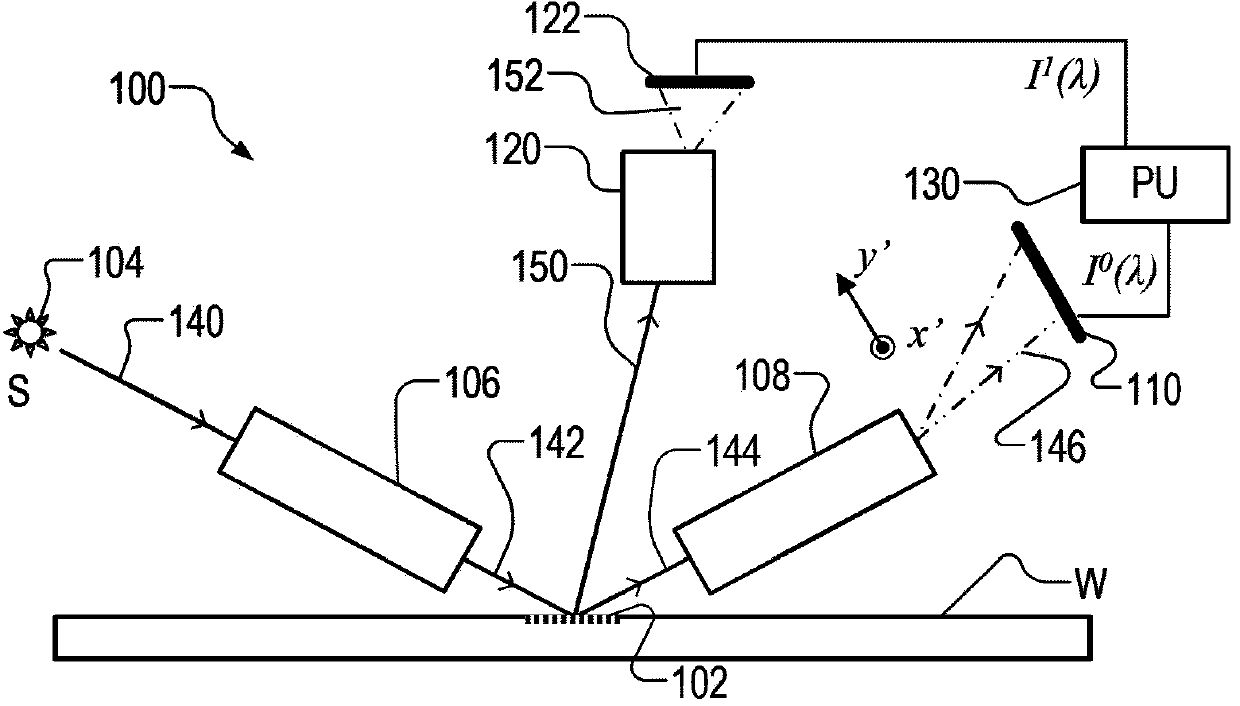

A technology for inspection equipment and detectors, applied in optomechanical equipment, microlithography exposure equipment, spectrum investigation, etc., can solve problems such as process influence height measurement, and achieve the effect of simple optical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] This specification discloses one or more embodiments that incorporate the features of this invention. The disclosed embodiments are merely illustrative of the invention. The scope of the invention is not limited to the disclosed embodiments. The invention is defined by the appended claims.

[0049] Embodiments are described, and references in the specification to "one embodiment," "an embodiment," "an exemplary embodiment," etc. indicate that the described embodiments may include particular features, structures, or characteristics, But not every embodiment must include a specific feature, structure or characteristic. Moreover, these phrases are not necessarily referring to the same embodiment. Furthermore, when particular features, structures or characteristics are described in conjunction with an embodiment, it should be understood that it is within the purview of those skilled in the art to implement those features, structures or characteristics in combination with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com