Pressurization solid phase extraction device

An extraction device and solid-phase extraction column technology, which is applied in the pretreatment field of analytical chemistry experiments, can solve the problems of unstable flow rate, long processing time, and high price, and achieve the effects of less air section, easy promotion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

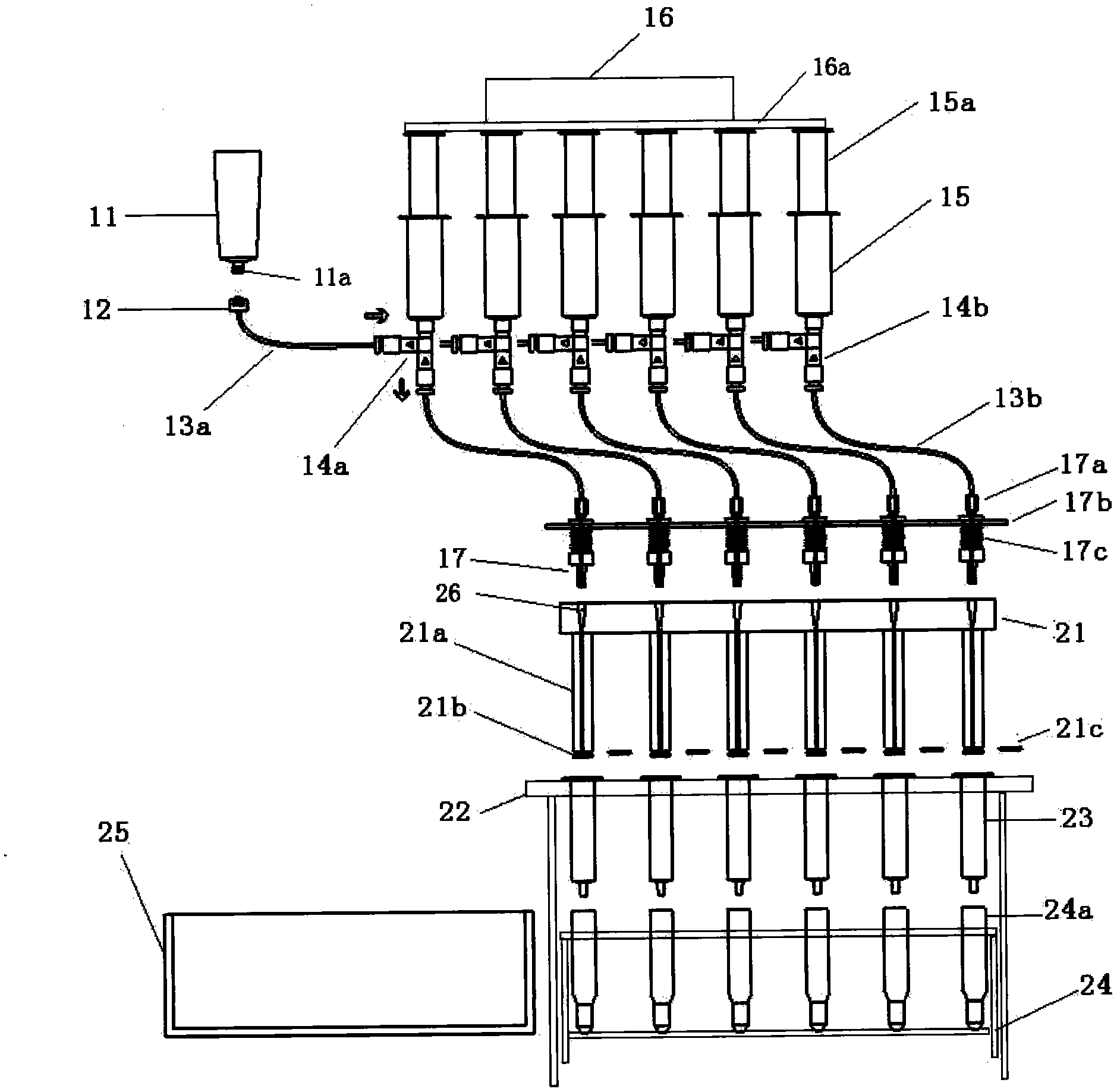

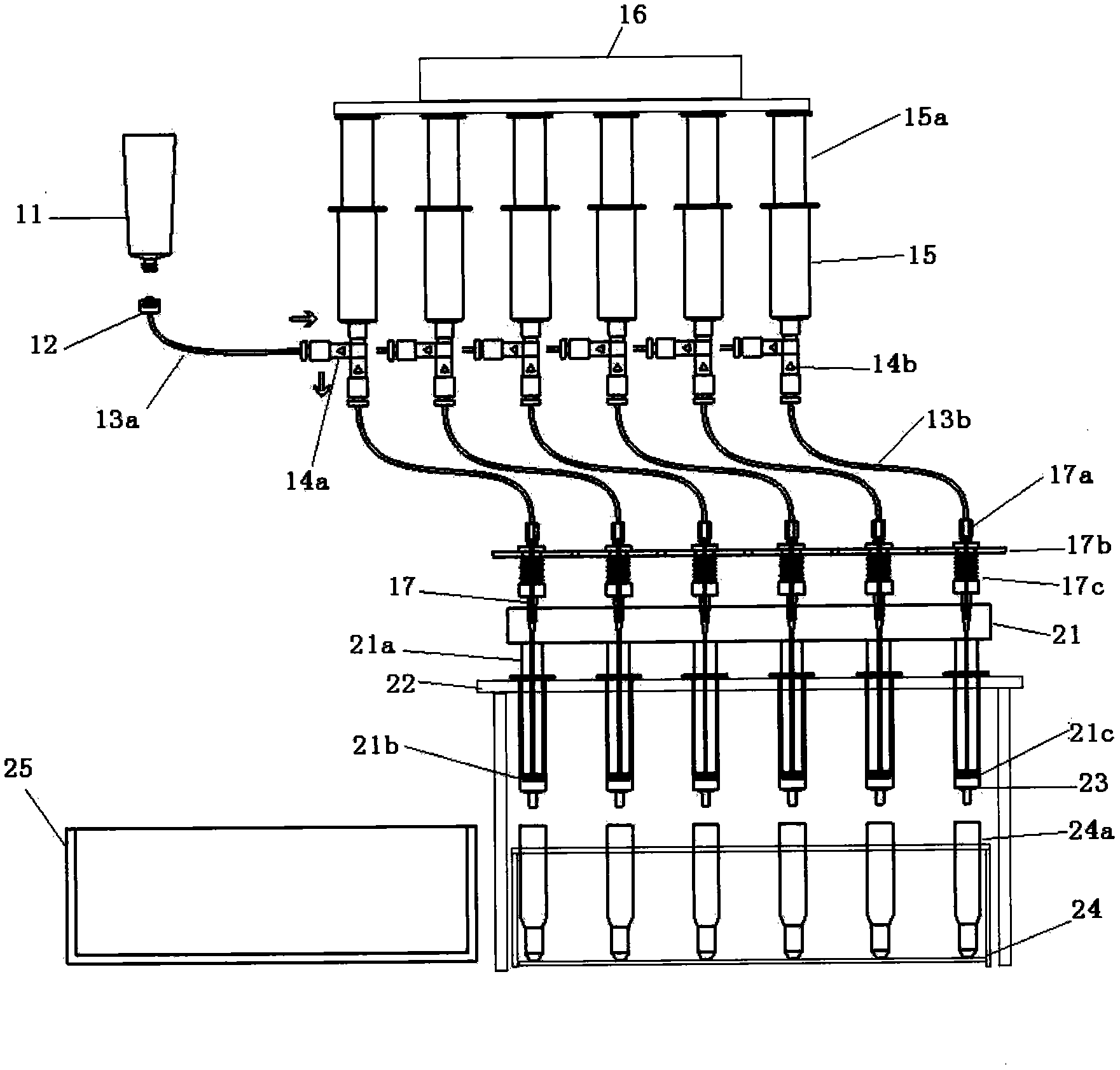

[0030] see figure 1 , taking the figure of six channels as an example, the pressurized solid phase extraction device of the present invention includes two parts: a pipetting component 1 and an extraction and elution component 2:

[0031] The pipetting assembly is provided with six pipetting channels, and each pipetting channel includes the following components: sample cup 11, female Luer connector 12, syringe pump 15, first one-way valve 14a, second one-way valve 14b, movable Connecting head 17, the first Teflon tube 13a, the second Teflon tube 13b; wherein the syringe pump 15 is upside down, and its function is to provide the power of pipetting for this channel, and the outlet is directly connected closely with two one-way valves, the first The one-way valve 14a only allows the liquid to enter the syringe pump, and the second one-way valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com