Dust-collecting grinding mobile purifier

A purifier and dust collection technology, applied in chemical instruments and methods, climate change adaptation, climate sustainability, etc., can solve the problems of reducing work efficiency, prolonging work cycle, increasing work burden, etc., to improve work efficiency and cost. Low cost and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

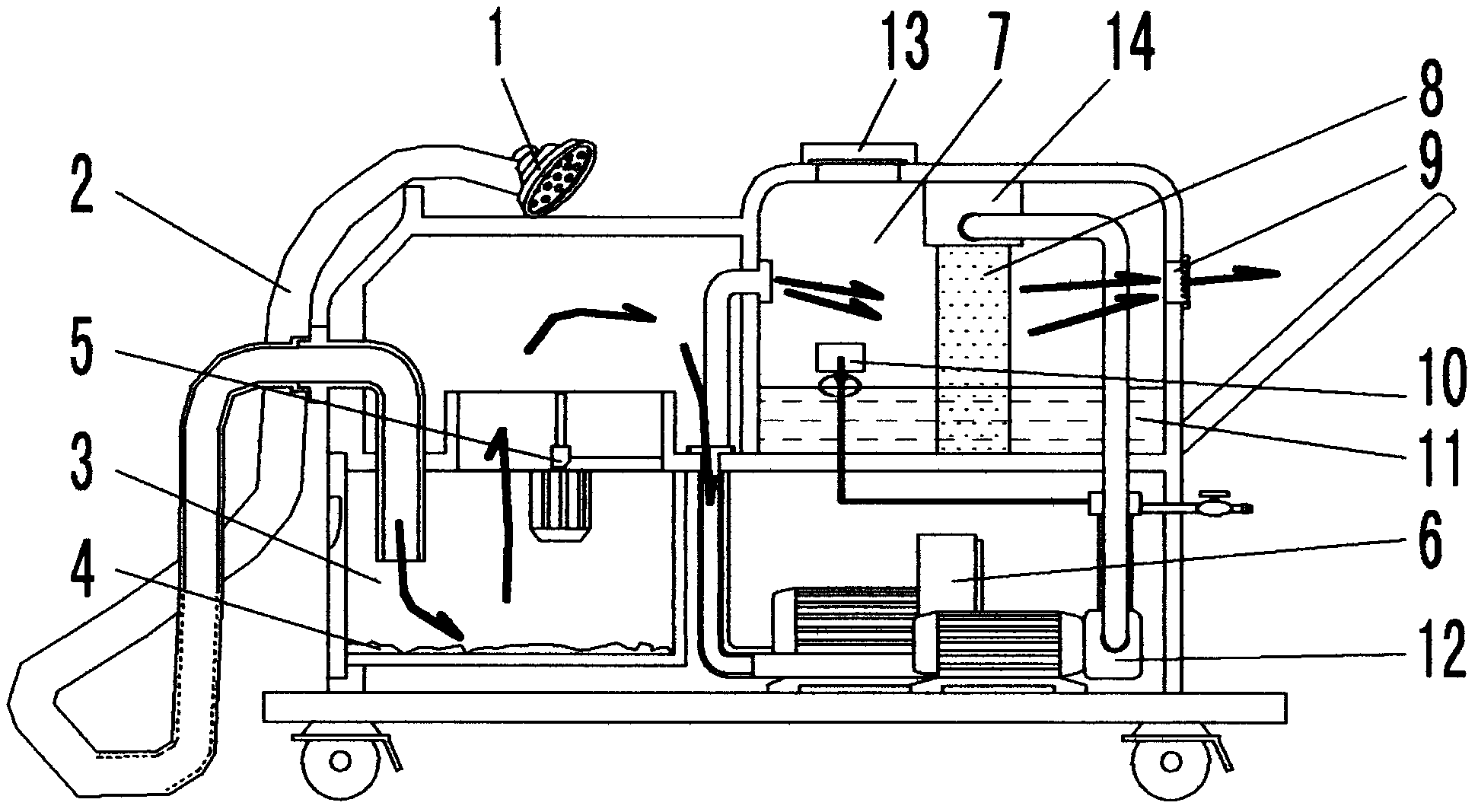

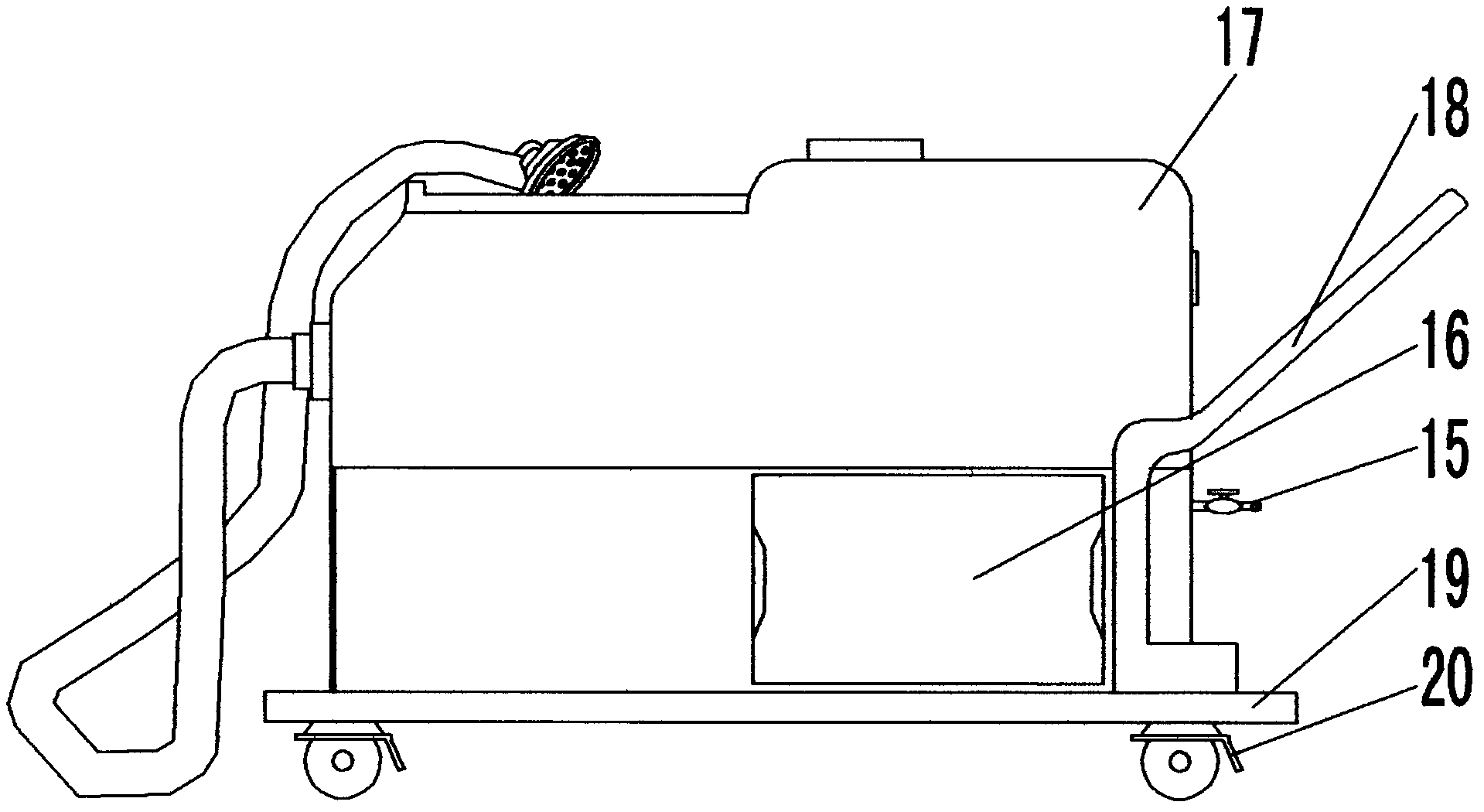

[0022] In order to make the objects, technical solutions and advantages of the present invention clearer to those skilled in the art, the present invention will be further elaborated below in conjunction with the accompanying drawings and examples.

[0023] The electric or pneumatic abrasive tool (1) of this product is used to grind the inhaled flying dust. The inhaled flying dust is filtered through the stainless steel filter layer (5), and then passed through the microporous sponge (8) of the hydrolysis filter chamber (7). After hydrolysis and filtration treatment, the purified gas can be discharged safely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com